Side wall inner plate

A technology of side wall inner plate and reinforcing plate, which is applied in the directions of superstructure, sub-assembly of superstructure, transportation and packaging, etc., can solve problems such as cracking and poor toughness, and achieve the effect of increasing toughness and strengthening strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings.

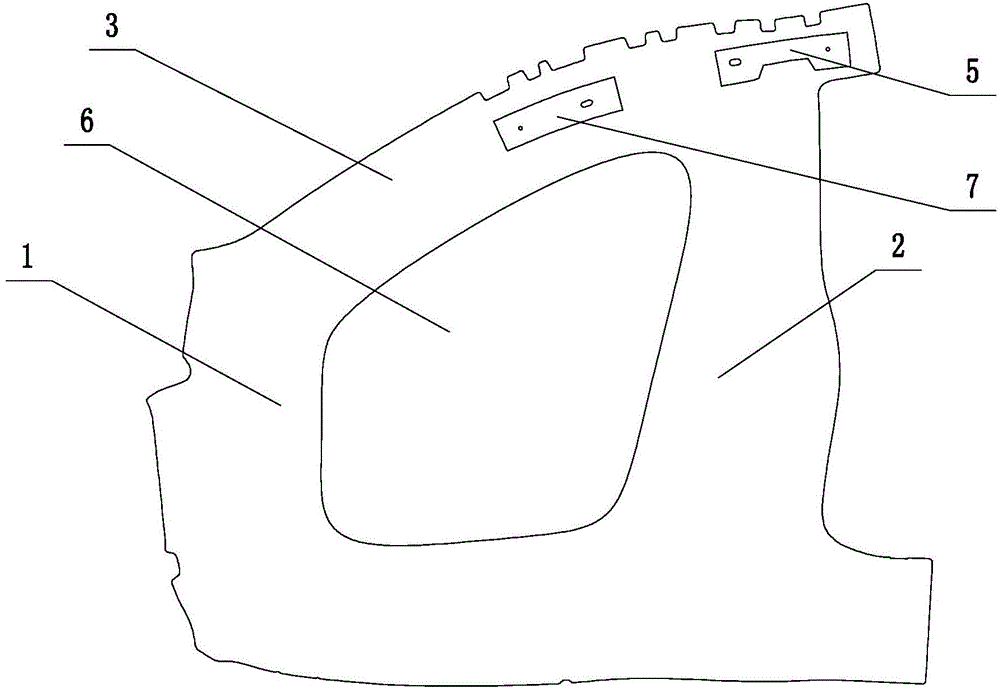

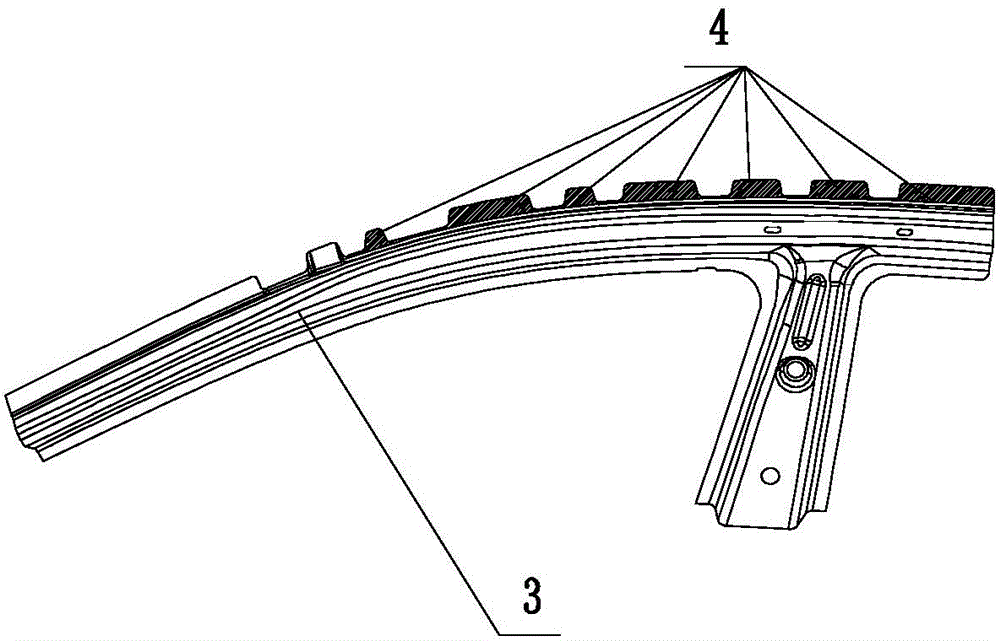

[0011] like Figure 1 ~ Figure 2 As shown: the side wall inner panel includes a side wall inner panel body 1, a B-pillar body 2, an A-pillar body 3, a flange surface 4, a first reinforcement plate 5, a windshield installation hole 6, and a second reinforcement plate 7 wait.

[0012] like figure 1 As shown, the present invention includes a side wall inner panel body 1, the side wall inner panel body 1 is a ring structure, one side of the ring structure is the B-pillar body 2, and the upper side of the ring structure is the A-pillar body 3; The main part of the inner plate body 1 is obtained by hot forming of ultra-high strength steel, and has a martensitic structure with a strength of 1300-1500 MPa; figure 2 As shown, the upper surface of the A-pillar body 3 is a flange surface 4 overlapping with the top cover. The flange surface 4 is obtained by slow cooling in the ultra-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Body thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com