Composite flexible flashing band and preparation method thereof

A flashing belt, flexible technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, snow traps, etc., can solve the problems of inability to use waterproof node processing technology, inability to solve waterproof requirements, and lack of air permeability, etc., to achieve Excellent aging resistance, obvious waterproof effect, excellent tensile and ductile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

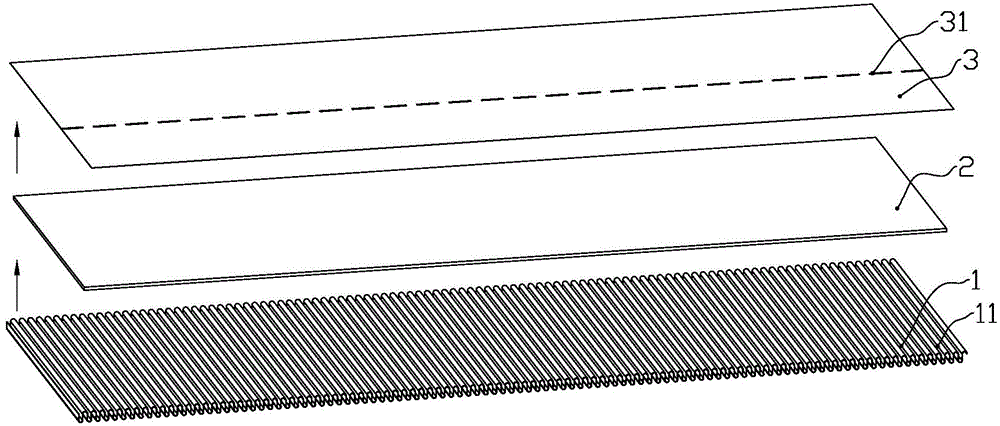

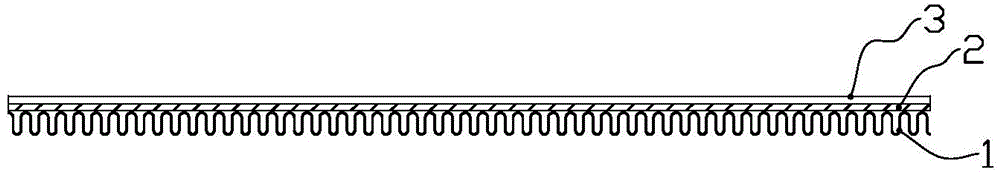

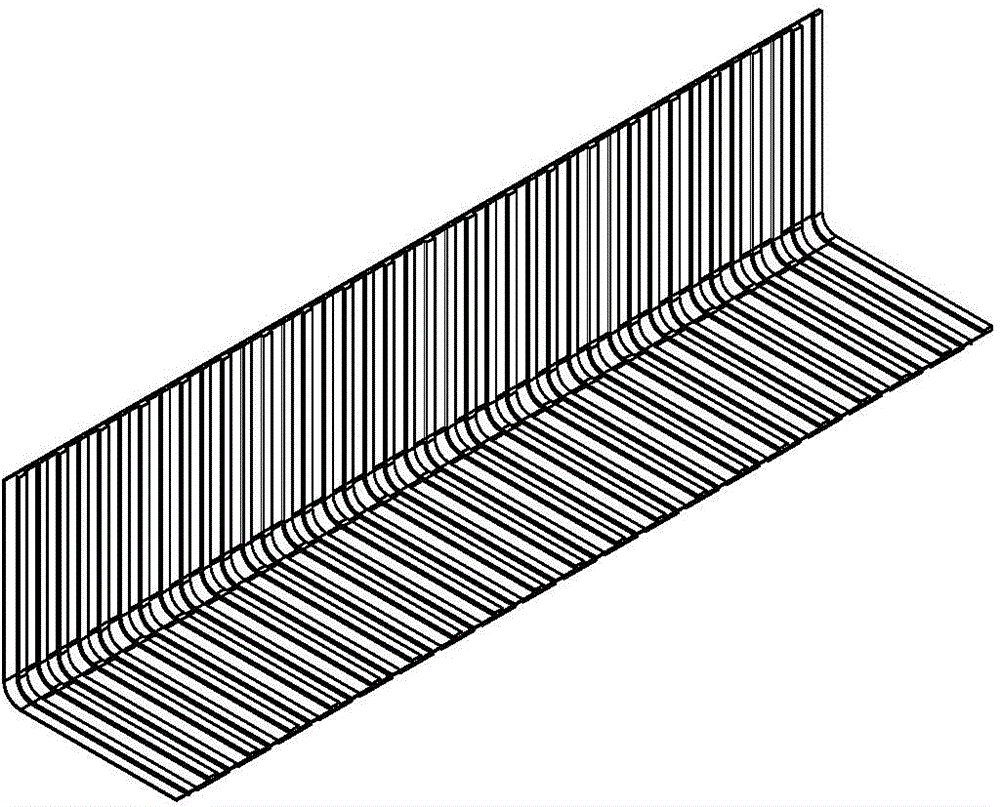

[0043] Such as Figure 1 to Figure 2 As shown, the composition of the composite flexible flashing tape includes three layers of spun-bonded olefin film substrate 1, butyl rubber 2 and single silicon white release paper substrate 3 from bottom to top. By selecting a spun-bonded olefin film with a thickness of 0.1 mm to 0.7 mm, and forming an elastic belt with wrinkles with no less than 80 wrinkles per 10 cm and a stretch rate of no less than 50% by extrusion, The setting of the pleats 11 fully considers the ductility, waterproofness and ease of use, and is a flexible flashing belt compounded with butyl rubber with a thickness of 1 mm to 2 mm through hot melting and other processes.

[0044] Optimally, the width of the above-mentioned flashing belt is designed to be 15 centimeters wide, too narrow to form effective waterproofing, too wide to waste materials, and a disconnection line 31 is provided at a third of the substrate, which can be conveniently It is bent and partly torn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com