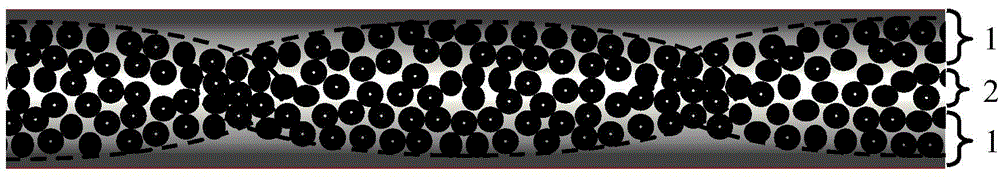

Preparation method of gradient prepreg with air guiding passage in layer

A prepreg, gradient technology, applied in the coating and other directions, can solve the problems of limiting the promotion and application of composite materials, high molding process costs, collapsed vacuum bag rupture, etc., so as to reduce the risk of collapse and vacuum bag rupture, and reduce process costs. , Improve the effect of surface viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0023] Select a typical high-temperature epoxy resin system to study its rheological properties, select the temperature point corresponding to the viscosity of 150Pa·s as the preparation temperature of the resin film, and the surface density of the single-sided film is 35.8g / m 2 . The domestic carbon fiber CCF300 is selected as the reinforcement, and the fiber surface density is 133g / m 2 . The resin content in the prepreg is about 35%. The composite operation of the gradient prepreg is carried out at 75°C. At this time, the viscosity of the adhesive film is about 100Pa·s, and the pressure of the pressing roller is adjusted to 0.4MPa, and then the preparation of the gradient prepreg with the function of air guiding is completed.

specific Embodiment 2

[0024] Select a typical high-temperature double-horse resin system to study its rheological properties, select the temperature point corresponding to the viscosity of 140Pa·s as the preparation temperature of the resin film, and the surface density of the single-sided film is 39.0g / m 2 . The domestic carbon fiber CCF800 is selected as the reinforcement, and the fiber surface density is 145g / m 2 . The resin content in the prepreg is about 35%. The composite operation of the gradient prepreg is carried out at 110°C. At this time, the viscosity of the adhesive film is about 90Pa·s, and the pressure of the pressing roller is adjusted to 0.3MPa, and then the preparation of the gradient prepreg with the function of air guiding is completed.

specific Embodiment 3

[0025] Select a typical cyanate resin system, study its rheological properties, select the temperature point corresponding to the viscosity of 150Pa·s as the preparation temperature of the resin film, and the surface density of the single-sided film is 76.7g / m 2 . The domestic quartz fiber fabric QW280 is selected as the reinforcement, and the fiber surface density is 285g / m 2 . The resin content in the prepreg is about 35%. The composite operation of the gradient prepreg is carried out at 100°C. At this time, the viscosity of the adhesive film is about 110Pa·s, and the pressure of the pressing roller is adjusted to 0.5MPa, and then the preparation of the fabric gradient prepreg with air guiding function is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com