Brick cutter for cement rotary kiln firebrick

A cement rotary kiln and refractory brick technology, applied in stone processing equipment, grinding machines, grinding/polishing equipment, etc., can solve problems such as time-consuming, inconvenient consignment, and physical hazards for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

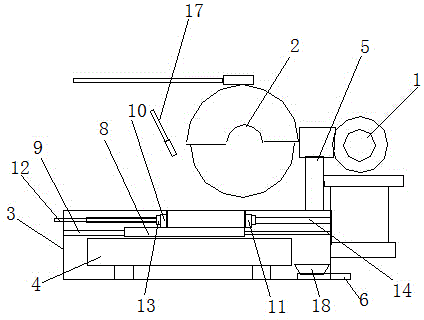

[0017] Such as figure 1 , 2 As shown, a brick cutter suitable for refractory bricks in a cement rotary kiln includes a motor 1 and a cutting wheel 2 driven by the motor, and a water shower nozzle 17 is provided at the same time. The vertical position of the lower part of the cutting wheel 2 is provided with a brick cutting Bracket 3, the brick body cutting bracket 3 is provided with a brick body fixing platform 4, and the brick body clamping structure on the brick body fixing platform is provided between the cutting wheel 2 and the brick body cutting bracket 3 A dust collector 5, and a dust suction pipe 6 is also arranged in the brick body cutting pallet 3 . The dust collector 5 is a rectangle and is hollowed out to the side and bottom of the cutting wheel 2 . The dust collector 5 collects the cutting dust and falls into the collection port 18 of the dust suction pipe 6 .

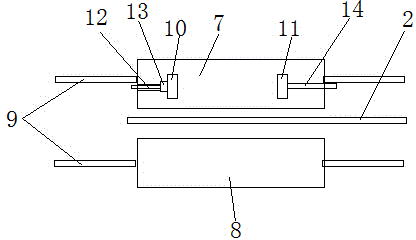

[0018] Described brick body fixed platform comprises left fixed platform 7, right fixed platform 8, an...

Embodiment 2

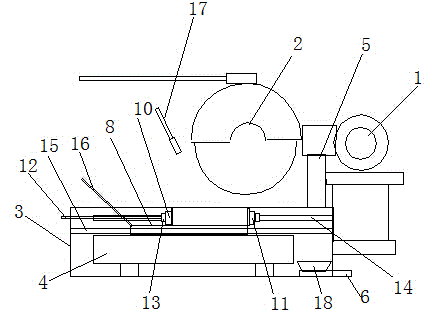

[0020] Example 2, such as image 3 As shown, on the basis of Embodiment 1, for the convenience of cutting and adjustment, a sliding rod 15 is arranged in the left fixed platform 7 and the right fixed platform 8, and is arranged at the left end of the left fixed platform 7 and the right fixed platform 8 There is a linkage pull rod 16.

[0021] The weight of the brick cutter is only 200 kg, and it is convenient for consignment; it is convenient to operate, reduces the workload of refractory bricks back and forth, reduces labor costs, and is equipped with a clamping device, so that the processing quality can meet the requirements of masonry; the addition of a dust collection device makes the processing When the dust is greatly reduced, the body of the operator is protected from injury;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com