A kind of easy-off and anti-blocking original edge ceramic tile forming mold

A technology for molding molds and ceramic tiles, which is applied in the field of powder molding, and can solve problems such as easy blockage of through holes, reduction of exhaust volume, and reduction of pressing speed, so as to prevent sedimentation or even blockage, protect the complete structure, and reduce demoulding resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] The present invention defines the corresponding up and down positions in use as upper and lower in turn; the side close to the center of the mold cavity 4 is defined as the inner side, and the other side away from the center of the mold cavity 4 is defined as the outer side accordingly; and refer to The flow direction of the gas defines the end where the gas enters as the front end, and correspondingly defines the other end where the gas exits as the rear end.

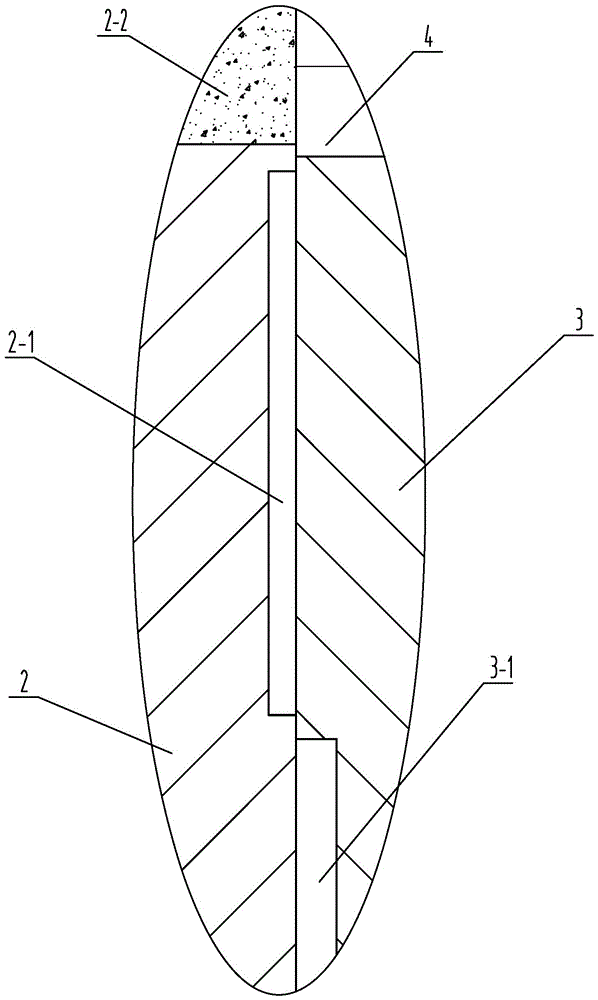

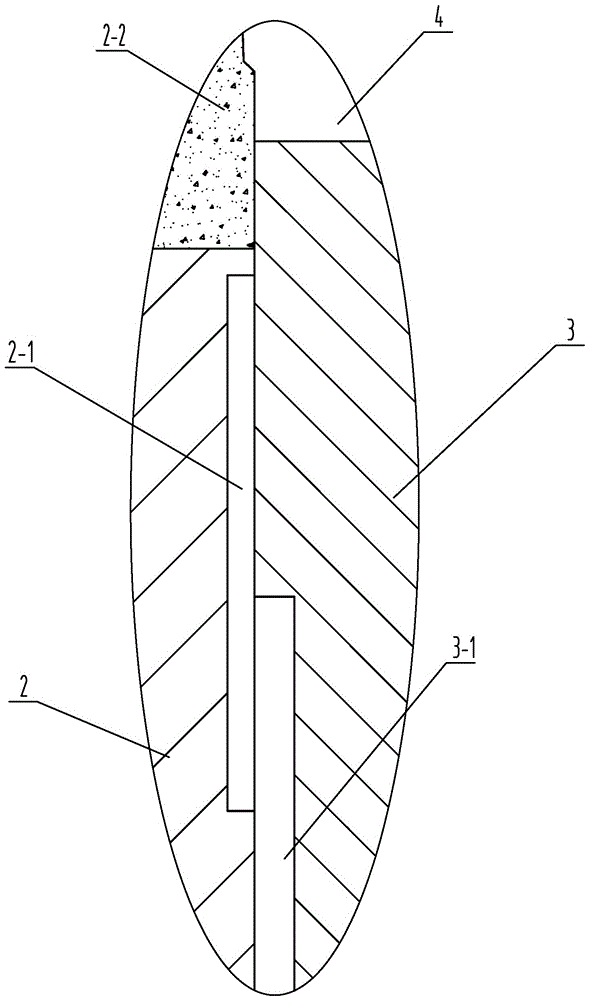

[0049] Such as figure 1 , Figure 4 , Figure 6 and Figure 7 As shown, the present invention is provided with an upper mold core 1 , a side plate and a lower mold core 3 that jointly surround a mold cavity 4 . An air passage 1-1 and a plurality of exhaust holes 1-2 are provided in the upper mold core 1, one end of the air outlet 1-2 is connected to the bottom surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com