Novel organic silicon defoaming agent with excellent stability and defoaming ability

A technology of silicone defoamer and stability, which is applied in the field of new emulsion type silicone defoamer, which can solve problems such as limitations, difficulty in developing the excellent properties of emulsion, and easy demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Embodiment 1: prepare 150g of emulsion type silicone defoamer, its preparation method is:

[0007] 1) Add silicone paste 10% + 3% compound emulsifier into a 250ml beaker (of which: 64% Pingping + 36% C 18 ~C 16 Alcohol)+CMC- HV 0.6%;

[0008] 2) Then use a heater to control a certain temperature (70 ° C ~ 80 ° C) to heat it into a molten state, stir it evenly with a glass rod, stop heating, and cool to room temperature;

[0009] 3) Finally, the defoamer was emulsified by a high-shear emulsifier at a speed of 10,000 r / min for 5 minutes while adding water to obtain the defoamer.

Embodiment 2

[0010] Embodiment 2: prepare 150g of emulsion type silicone defoamer, its preparation method is:

[0011] 1) Add silicone paste 10% + 3% compound emulsifier into a 250ml beaker (of which: 64% Pingping + 36% C 18 ~C 16 Alcohol)+CMC- HV 0.6% + diethylene glycol methyl ether 2%;

[0012] 2) Then use a heater to control a certain temperature (70 ° C ~ 80 ° C) to heat it into a molten state, stir it evenly with a glass rod, stop heating, and cool to room temperature;

[0013] 3) Finally, the defoamer was emulsified by a high-shear emulsifier at a speed of 10,000 r / min for 5 minutes while adding water to obtain the defoamer.

Embodiment 3

[0014] Embodiment 3: prepare 150g of emulsion type silicone defoamer, its preparation method is:

[0015] 1) Add silicone paste 10% + 3% compound emulsifier into a 250ml beaker (of which: 64% Pingping + 36% C 18 ~C 16 Alcohol)+CMC- HV 0.6% + diethylene glycol methyl ether 3%;

[0016] 2) Then use a heater to control a certain temperature (70 ° C ~ 80 ° C) to heat it into a molten state, stir it evenly with a glass rod, stop heating, and cool to room temperature;

[0017] 3) Finally, the defoamer was emulsified by a high-shear emulsifier at a speed of 10,000 r / min for 5 minutes while adding water to obtain the defoamer.

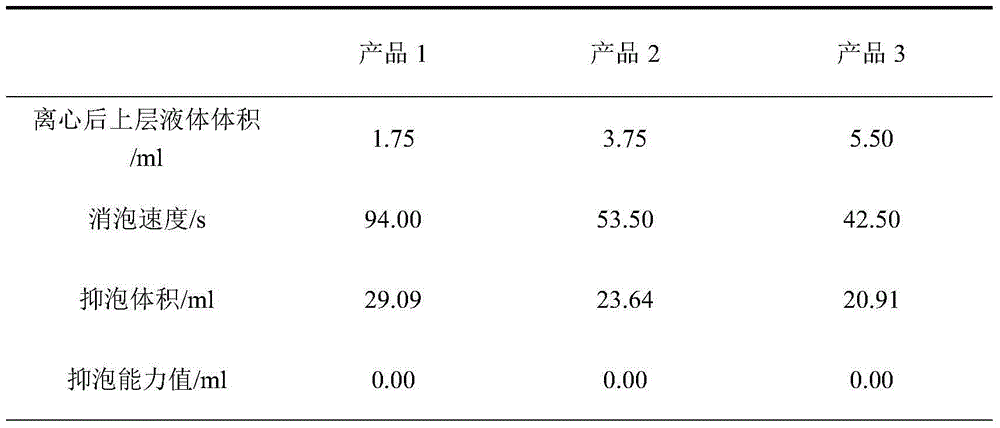

[0018] Performance evaluation:

[0019] 1) Preparation of foaming liquid: Accurately weigh K12 (sodium lauryl sulfate) foaming agent, dissolve it in standard mineralized water (CaCl 2 5.2g / L, MgCl 2 .6H 2 O 3.5g / L, Na 2 SO 4 7.0g / L, NaCl14.3g / L), be made into 0.05% foaming agent mineralized aqueous solution.

[0020] 2) Preparation of defoaming solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com