A kind of biological glass-sodium alginate composite biological material and its kit and application

A composite biomaterial, sodium alginate technology, applied in the field of curable bioglass-sodium alginate composite biomaterial and its preparation, can solve the problem of poor clinical operability, long curing time and unsatisfactory antibacterial effect of mineral trioxide aggregates and other issues, to achieve excellent biological activity and biocompatibility, and to promote the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

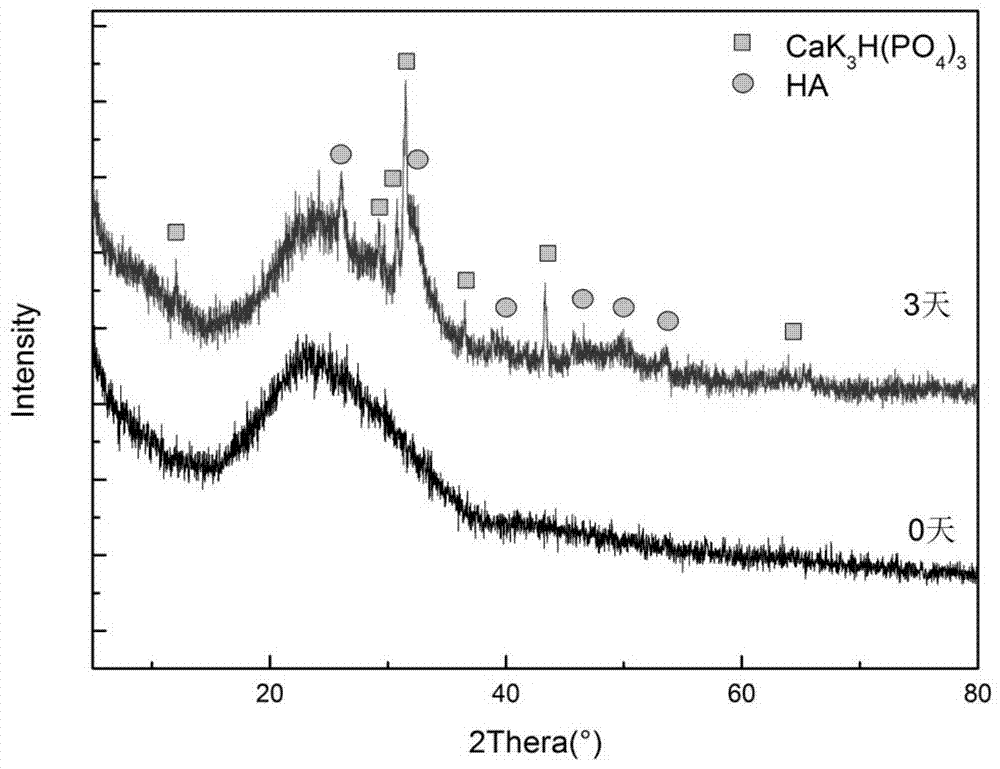

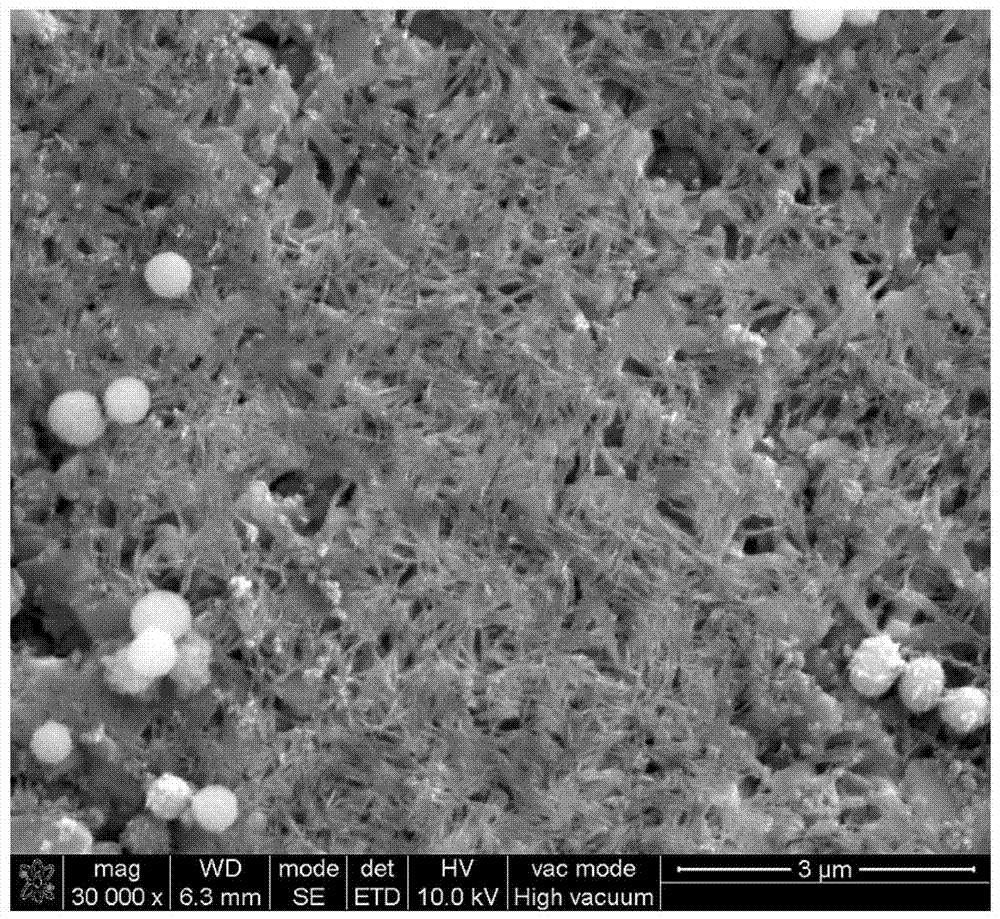

Embodiment 1

[0032] Step 1: Preparation of bioglass nanospheres

[0033] Using tetraethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate as raw materials, weigh the corresponding substances in molar ratio, so that the oxides corresponding to each substance in the raw materials are calculated according to the SiO 2 :P 2 o 5 : The molar percentage of CaO was 40:5:55 to prepare bioglass nanospheres. Dissolve 4g of dodecylamine in a mixed solution of 105mL deionized water and absolute ethanol. During the synthesis process, the temperature is controlled at 40°C. After stirring for 10 minutes, 16.00mL of ethyl orthosilicate, 16.32mL of triethyl phosphate, 28.25g Calcium nitrate tetrahydrate, the interval between each feeding is 30min. Stirring was continued for 3 hours after the addition was completed, a white emulsion was obtained, and a wet powder was obtained after centrifugation. The powder is freeze-dried, placed in a box-type electric furnace, and subjected to heat...

Embodiment 2

[0039] According to Example 1, ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate are used as raw materials, and the corresponding substances are weighed in molar ratios, so that the oxides corresponding to each substance in the raw materials are calculated according to the SiO 2 :P 2 o 5 : The molar percentage of CaO was 37:8:55 to prepare bioglass nanospheres. The specific operation of Step 1 is the same as that of Embodiment 1.

[0040] Step 2: Preparation of Phosphate Buffered Solidification Solution

[0041] Dipotassium hydrogen phosphate and sodium dihydrogen phosphate are added to a certain amount of water in turn to obtain a phosphate buffer solution. The phosphate concentration was 4M and the pH of the solution was 7.

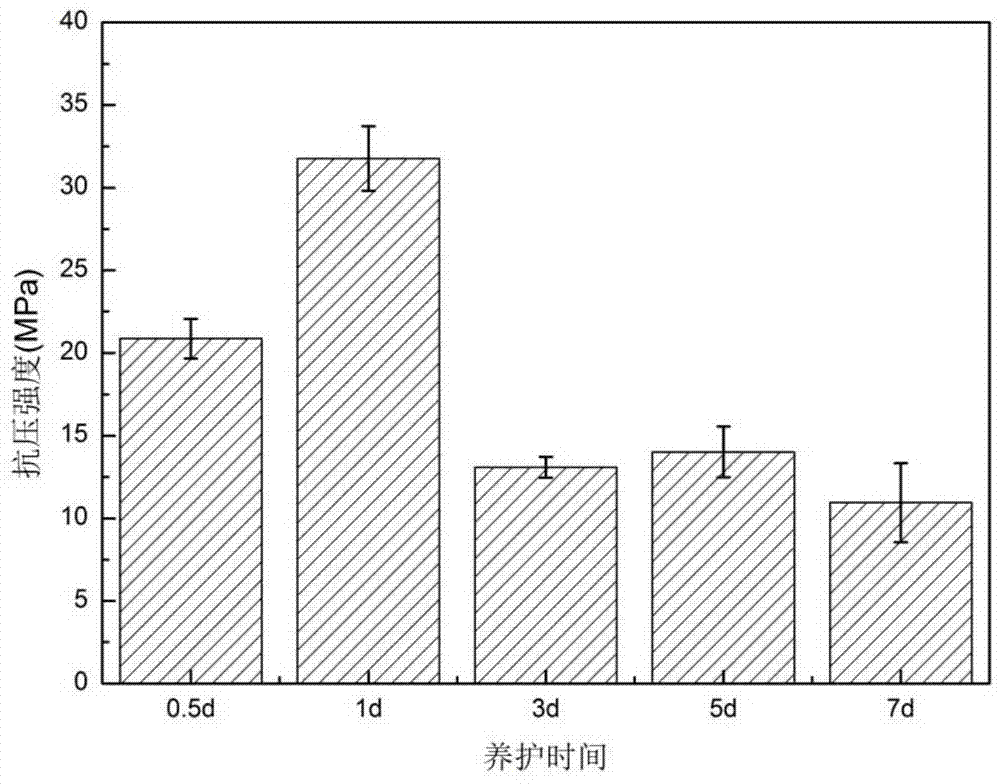

[0042] Step 3: Preparation of bioglass-sodium alginate composite biomaterial:

[0043]The solid powder prepared above was mixed with the solidification solution at 1.60 g / mL to form a paste. Fill the reconciled paste into a...

Embodiment 3

[0045] According to Example 1, ethyl orthosilicate, triethyl phosphate, and calcium nitrate tetrahydrate are used as raw materials, and the corresponding substances are weighed in molar ratios, so that the oxides corresponding to each substance in the raw materials are calculated according to the SiO 2 :P 2 o 5 : The molar percentage of CaO was 37:8:55 to prepare bioglass nanospheres. The specific operation of Step 1 is the same as that of Embodiment 1.

[0046] Step 2: Preparation of Sodium Alginate Phosphate Buffer Solidification Solution

[0047] Weigh sodium alginate and dissolve it in deionized water to prepare sodium alginate solution. Dipotassium hydrogen phosphate and sodium dihydrogen phosphate were sequentially added to the sodium alginate solution to obtain a 0.5% alginic acid phosphate buffer solution with a phosphate concentration of 4M.

[0048] Step 3: Preparation of bioglass-sodium alginate composite biomaterial:

[0049] The solid powder prepared above wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com