Method for preparing biological enzyme drink

A bio-enzyme and drink technology, applied in the field of preparation of bio-enzyme drinks, can solve the problems of long fermentation time, unfavorable industrial production, difficult control of fermentation conditions, etc., and achieve the effect of high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

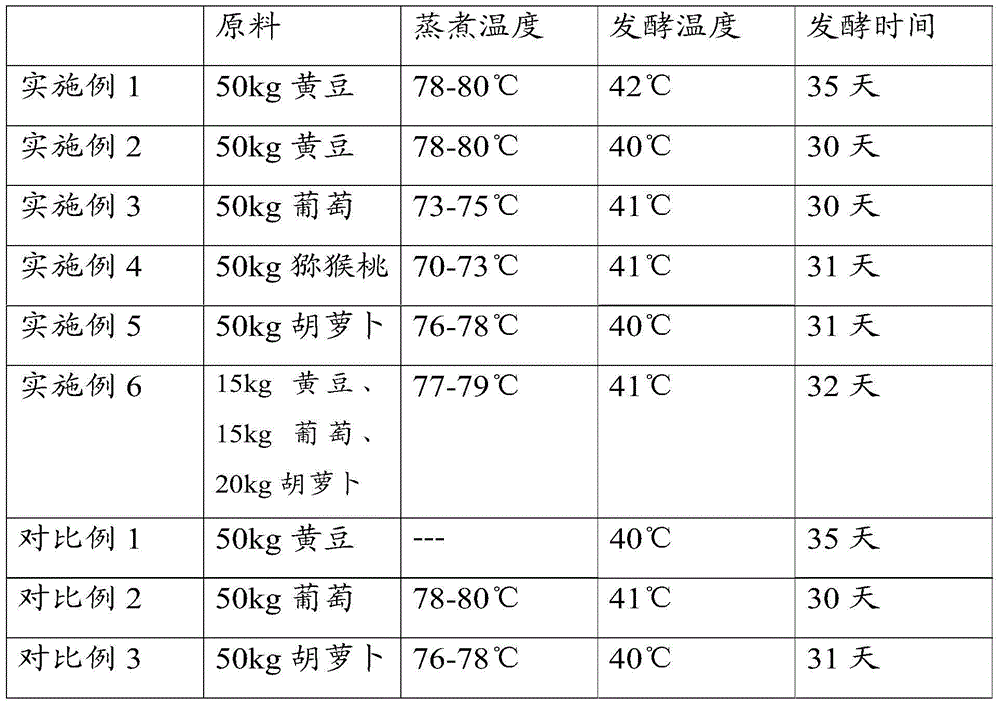

Examples

Embodiment 1

[0043]Select 50kg of fresh soybeans without bad seeds, wash them and put them in a steamer for cooking, keeping the temperature of the water vapor in the steamer at 78-80°C; after cooking, add 16.7kg of pure water to the steamed soybeans , and then sealed; after sealing, ferment at 42°C for 35 days.

Embodiment 2

[0045] Select 50kg of fresh soybeans without bad seeds. Because the hardness of soybeans is relatively high, soak the selected soybeans in clear water for 3 hours to ensure that they are evenly cooked during cooking; put the soaked soybeans into a steamer for steaming. Maintain the temperature of the water vapor in the steamer at 78-80°C; after cooking, cool the steamed soybeans to room temperature naturally, then add 12.5kg of pure water, and then seal; after sealing, ferment at 40°C for 30 days.

[0046] After the fermentation is over, the solid-liquid mixture is obtained, the supernatant is collected, and it is injected into a diatomite filter device for filtration, and impurities and various harmful microorganisms are further removed to ensure the taste and purity of the product; the end of filtration Finally, it is sterilized by a pasteurization machine, the sterilizing temperature is set to 70° C., and the sterilizing time is 1 minute.

Embodiment 3

[0048] Select 50kg of fresh, non-rotten grapes, wash them and put them in a steamer for steaming, keeping the temperature of the steam in the steamer at 73-75°C; after cooking, cool the steamed soybeans to room temperature naturally, then Add 11.2kg of pure water; in order to ensure that the grapes are evenly mixed with the pure water, stir after adding water, and seal after stirring; after sealing, ferment at 41°C for 30 days.

[0049] After the fermentation is over, the solid-liquid mixture is obtained, the supernatant is collected, and it is injected into a diatomite filter device for filtration, and impurities and various harmful microorganisms are further removed to ensure the taste and purity of the product; the end of filtration Finally, it is sterilized by a pasteurization machine, the sterilizing temperature is set to 80° C., and the sterilizing time is 1 minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com