Mobile terminal

A mobile terminal and mobile technology, which is applied in the construction parts of electrical equipment, telephone communications, instruments, etc., can solve problems such as low cost, damage, and impact on product safety, and achieve low cost, improved safety, and improved heat dissipation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments according to the present invention will be described with reference to the drawings. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

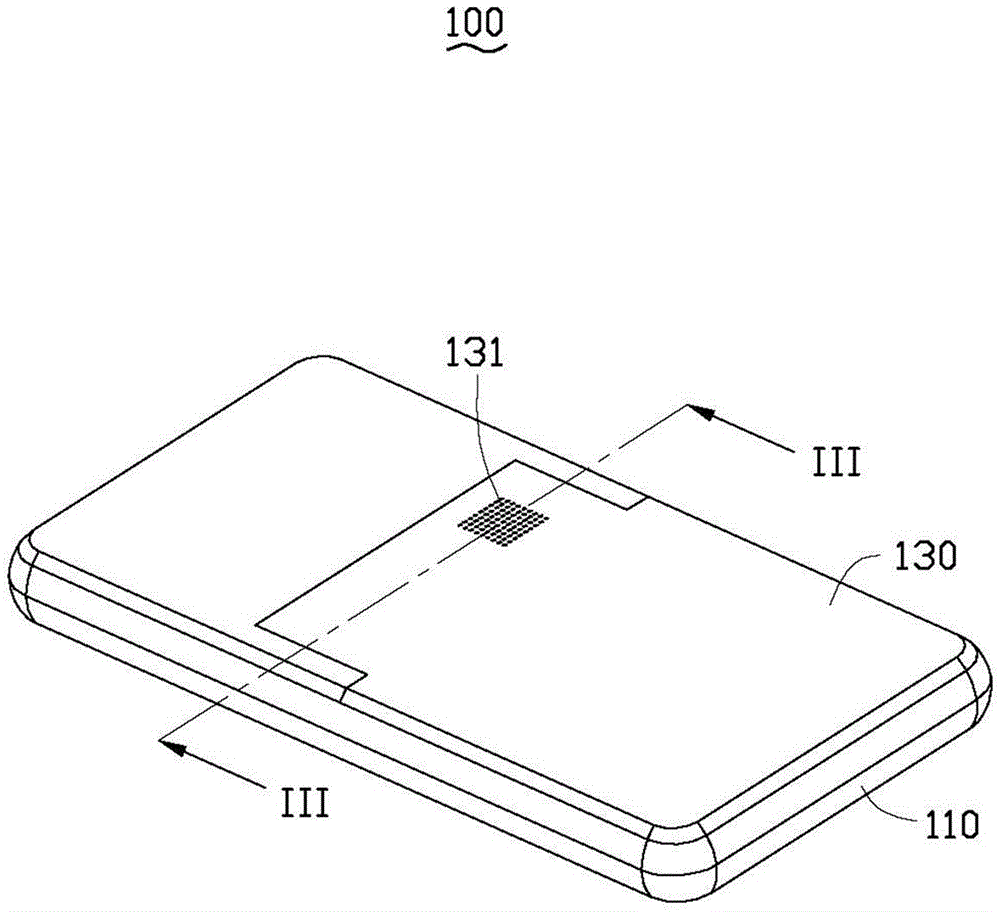

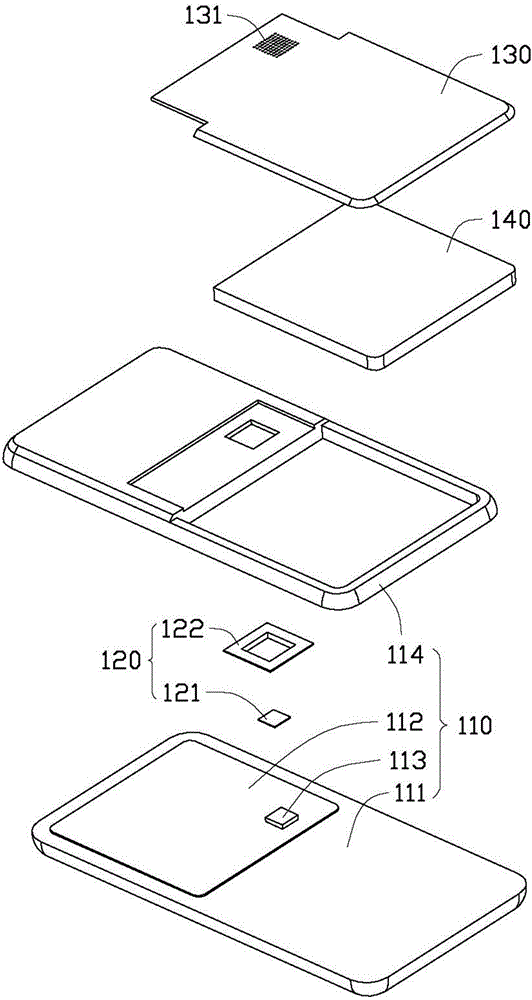

[0018] see figure 1 and figure 2 , the mobile terminal 100 in the first embodiment of the present invention includes a body 110 , a heat sink 120 and a rear cover 130 . The heat dissipation part 120 is disposed inside the body 110 and is covered by a rear cover 130 . The rear cover 130 is movably connected to the body 110 . The rear cover 130 can be a battery button cover for sealing the battery 140 .

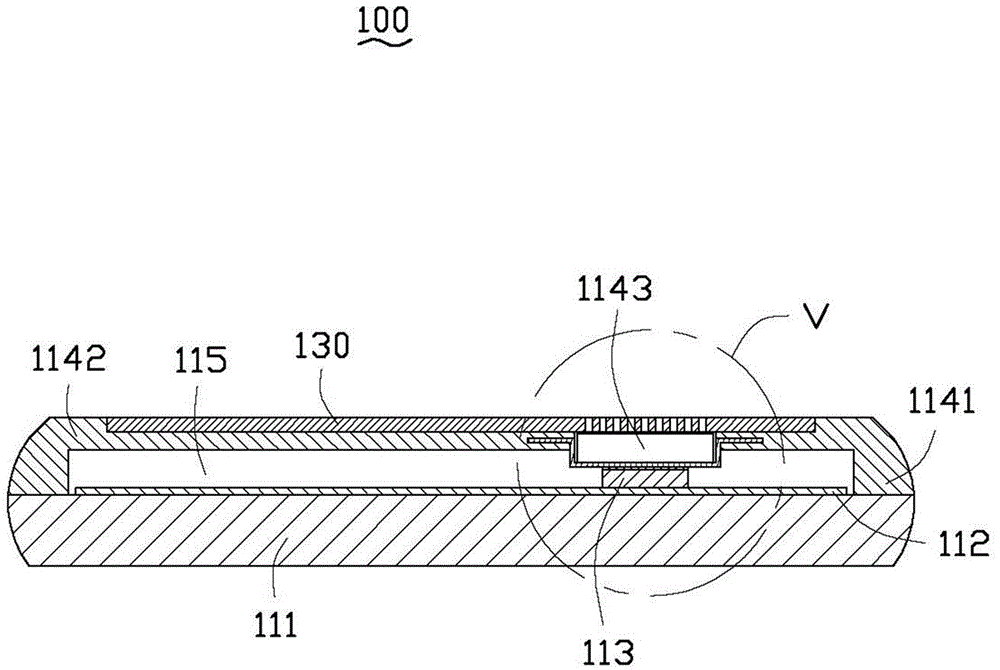

[0019] Please also refer to image 3 , the body 110 includes a front panel 111 , a circuit substrate 112 , a heating element 113 and a rear panel 114 . The front panel 111 can be used for installing components such as a display screen and buttons. The circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com