Asynchronous motor soft starter based on single-chip microcomputer

A technology of asynchronous motor and soft starter, applied in the field of soft start, which can solve problems such as large starting torque, reduced service life of the motor, overheating of the motor, etc., and achieves the advantages of small impact torque and impact current, simple control and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

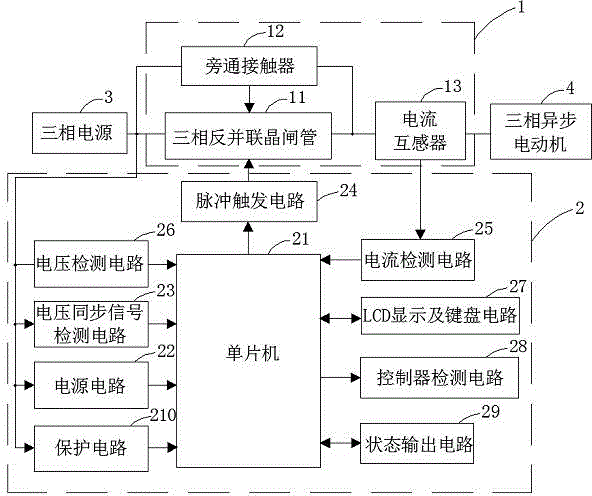

[0022] Such as figure 1 As shown, the soft starter for an asynchronous motor based on a single-chip microcomputer includes a main circuit 1 and a control circuit 2. The main circuit 1 and the control circuit 2 are connected to a three-phase power supply 3. The main circuit 1 consists of three groups of anti-parallel thyristors 11 and a bypass contactor 12. Composed of a current transformer 13, the control loop 2 is composed of a single-chip microcomputer 21 and a power supply circuit 22 connected thereto, a voltage synchronization signal detection circuit 23, a pulse trigger circuit 24 for generating a thyristor gate trigger signal, a current detection circuit 25, and a voltage detection circuit 26. LCD display and keyboard circuit 27, contactor control circuit 28, state output circuit 29 and protection circuit 210, single-chip micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com