Buried enhanced and modified polypropylene ripple cable sleeve

A cable sleeve, polypropylene technology, applied in the field of wires and cables, can solve the problems of aging resistance and friction performance deviation, small ring stiffness inner wall friction coefficient, low low temperature impact strength, etc., to achieve improved aging resistance performance, inner wall friction coefficient Small, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

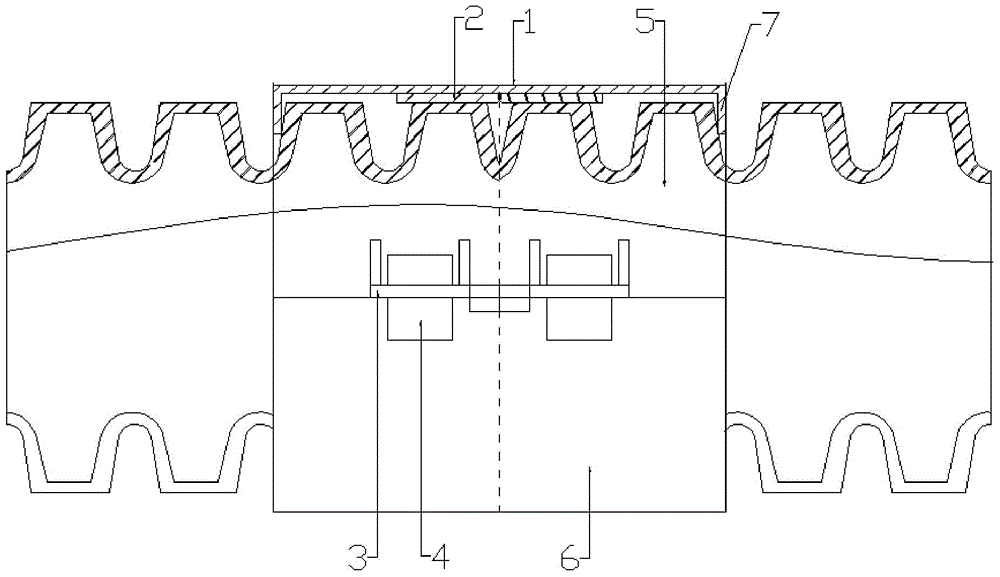

[0019] Such as figure 1 , figure 2 As shown, a buried reinforced modified polypropylene corrugated cable sleeve includes a single-wall corrugated pipe wall extending along the length direction of the sleeve, a buckle fitting 1 and a sealing ring 2;

[0020] The outer wall of the single-wall bellows is provided with several annular protrusions, the cross-section of the annular protrusions is isosceles trapezoidal, and the circular arc transitions between the annular protrusions;

[0021] The inner wall of the sealing ring 2 is socketed on one end of the outer wall of the single-wall corrugated pipe; the inner wall of the buckle pipe fitting 1 is socketed on the outer wall of the sealing ring 2 for connecting two walls of the single-wall corrugated pipe;

[0022] The buckle pipe fitting 1 includes a first pipe fitting 5 and a second pipe fitting 6 that are both arched; the arc-shaped sides of the first pipe fitting 5 and the second pipe fitting 6 are provided with vertical sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com