Nanocomposite, method for preparing nanocomposite, and lithium ion battery

A nano-composite material and nano-layer technology, applied in the field of nano-materials, can solve the problems of easy aggregation of nano-materials, easy formation of lithium dendrites, and material pulverization, and achieve excellent cycle stability, high-rate discharge performance, and high surface reaction. Active, material non-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (2) The preparation method of the nanocomposite

[0043] The preparation method of the nanocomposite material described in the above-mentioned technical scheme, comprises the steps:

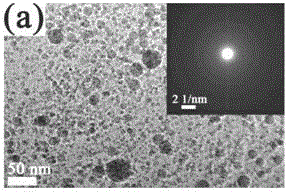

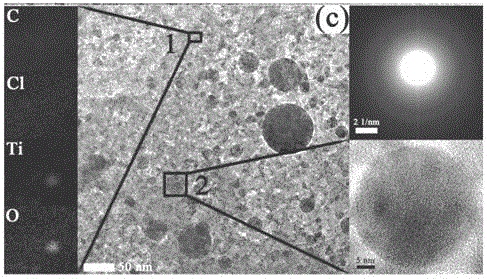

[0044] Step 1, adopt Hummers method to prepare the mixed solution of graphite oxide and hydrochloric acid, and in the mixed solution of graphite oxide and hydrochloric acid, adopt rotating TiO 2 The target is subjected to liquid phase laser ablation to produce amorphous TiO 2 In situ grown highly active TiO 2 / GO Composite.

[0045] Step 2, for the highly active TiO produced in step 1 2 / GO composite material is stirred in an ice bath, after stirring for half an hour, aniline monomer is added, and after stirring evenly (usually it takes half an hour to achieve a uniform state of stirring), ammonium persulfate is added for oxidative polymerization, thereby obtaining PANI / TiO 2 / GO ternary nanocomposites.

[0046] Specifically, it is best to carry out the treatment of step 2 quickly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com