Device for accurately measuring pressure difference of slag hole of gasification furnace and measurement method thereof

An accurate measurement and gasifier technology, which is used in measurement devices, measurement of fluid pressure, granular/powder fuel gasification, etc., can solve the problem of not being able to accurately and timely reflect the actual state of the gasifier slag mouth, and reduce accidents. The number of stops and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

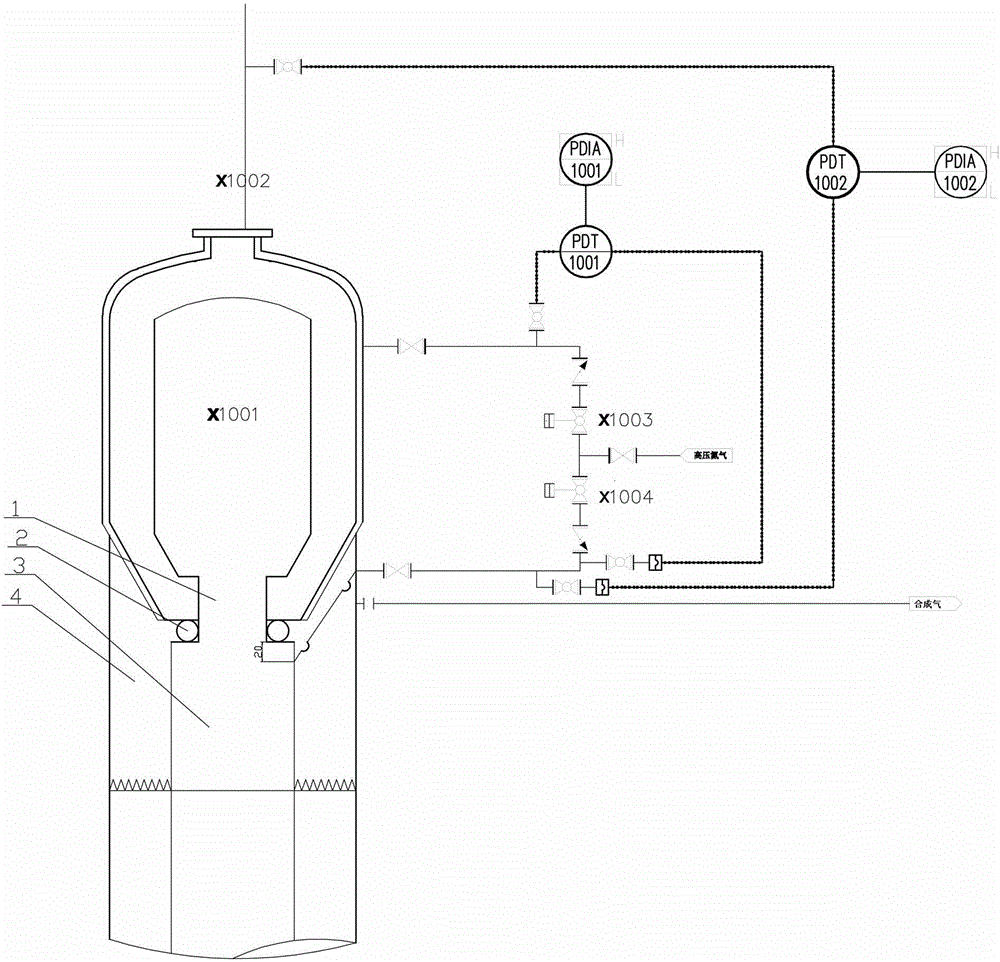

[0023] The original slag hole pressure differential pressure measurement method is the difference between the pressure of the combustion chamber X1001 of the gasifier and the pressure of the synthesis gas pipeline out of the gasifier (see attached figure 1 ).

[0024] The measurement of the pressure in the combustion chamber of the hot-wall gasifier is generally to reserve a pressure-taking flange on the furnace wall, using the "blowing method" (1.5Nm 3 The low flow rate of high pressure nitrogen per hour is continuously fed into the gasifier) for pressure measurement; the pressure measurement of the combustion chamber of the cold wall gasifier is generally through the flame protection nitrogen channel. The gasifier flame detector X1002 (referred to as the flame detector) is a device that monitors the combustion state in the furnace during the ignition and operation of the cold-wall gasifier. The flame detection signal enters the safety interlock system, and the flame detection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com