Yaw-control system and method based on frequency converter effective damping

A technology of yaw system and frequency converter, applied in the direction of machine/engine, wind engine control, engine function, etc., can solve the problems of wind power generation system safety threat, yaw actuator damage, tower, blade vibration, etc. Achieve the effect of preventing premature damage of gear teeth, reducing damage, and smooth operation of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

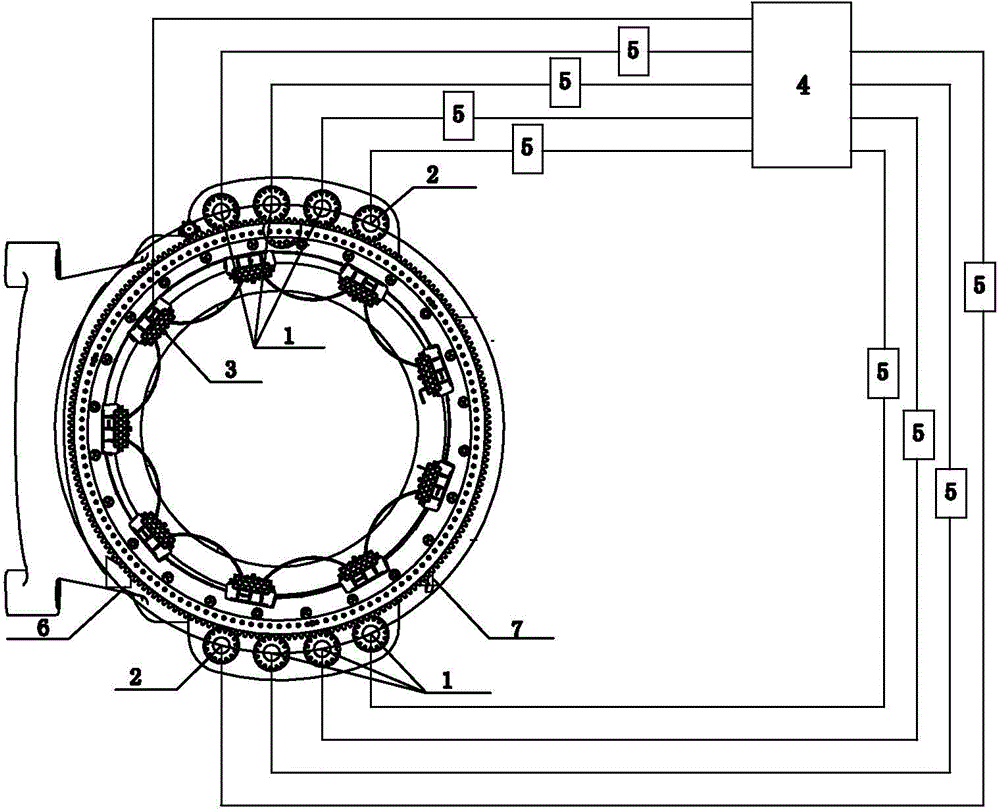

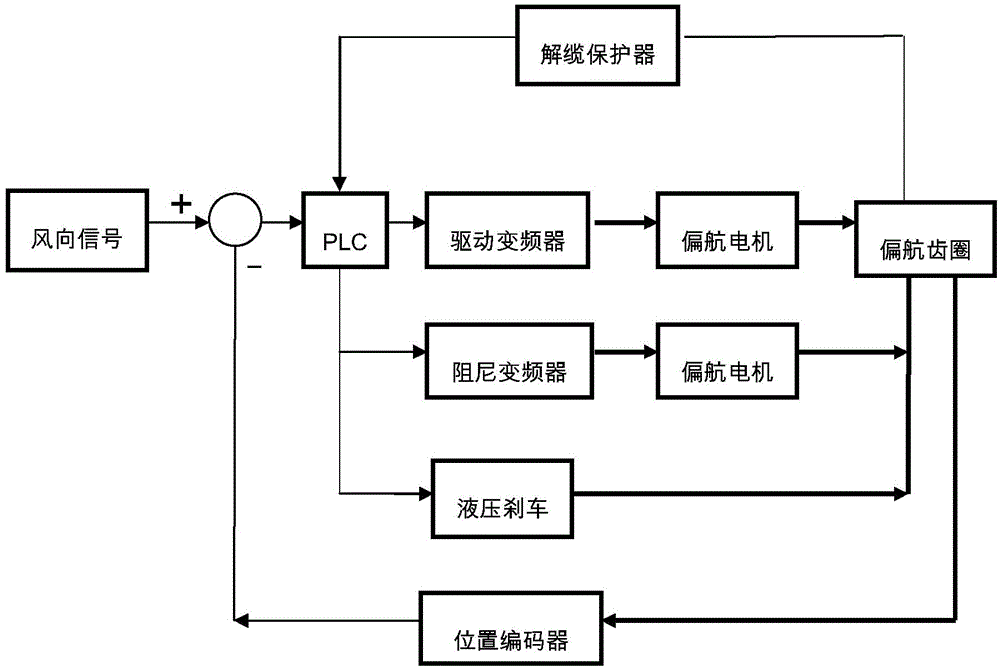

[0024] Example: such as figure 1 As shown, the yaw system includes a main control controller 4, 8 sets of frequency converters 5, 8 yaw motors, a braking system 3, a cable unwinding protector 6, and a position encoder 7. The 8 sets of frequency converters are independently Drive 8 yaw motors, 6 of the 8 yaw motors are yaw drive motor 1, 2 are yaw damping motor 2 during start and stop, 1 position encoder 7 and 1 uncable protector 6 are respectively installed on the yaw ring gear, and 8 groups of frequency converters 5, uncable protectors 6, and position encoders 7 are respectively connected to the main controller 4.

[0025] This example is used for a 1.5MW wind turbine. Two sets of yaw motors are selected and evenly arranged on the circumference of the yaw ring gear.

[0026] Wherein the uncable protector 6 is a conventional part of the existing wind turbine.

[0027] The frequency converters 5 all adopt four-quadrant frequency converters. The brake system 3 is a hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com