Rotary jet self-priming type short-range strengthening foam production device for dust suppression of coal mining machine

A coal mining machine, self-priming technology, applied in the field of rotary jet self-priming short-range enhanced foam production device, can solve the problems that are not suitable for the time and space conditions of the machine mining face, difficult to meet the efficient dust suppression of the coal mining machine, and the geometry of the foaming device Long scale and other issues, to achieve the effect of improving stability and economy, high reliability, and improving the ability to absorb air and blowing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

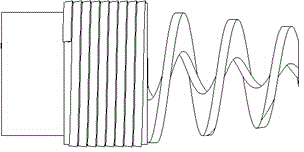

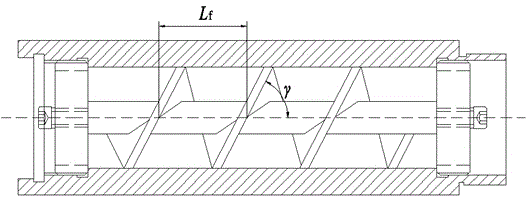

[0018] Example 1: Such as figure 1 As shown, the rotating jet self-priming short-range enhanced foam generating device used for coal shearer dust suppression in the present invention is mainly composed of a pressure water supply pipe 1, a swirl nozzle 2 and a jet foaming cylinder 3. The pressure water The supply pipe 1 is connected with the swirl nozzle 2, and the jet foaming cylinder body 3 is sequentially provided with an air suction chamber 4, a liquid suction chamber 5, a mixing throat 6, a pressurized foam chamber 7, an enhanced foam production chamber 8 and a speed-increasing outlet. flow chamber9. Wherein, the swirl nozzle 2 is screwed into the suction chamber 4 in the jet foaming cylinder 3 through threads, and the cavity of the suction chamber 4 is a tapered structure, and its contraction angle α 1 =30°, the suction chamber 4 is provided with an oblique suction hole 10; the cavity of the liquid suction chamber 5 is a tapered structure, and its contraction angle α ...

Embodiment 2

[0019] Example 2: Such as figure 1 As shown, the rotating jet self-priming short-range enhanced foam generating device used for coal shearer dust suppression in the present invention is mainly composed of a pressure water supply pipe 1, a swirl nozzle 2 and a jet foaming cylinder 3. The pressure water The supply pipe 1 is connected with the swirl nozzle 2, and the jet foaming cylinder body 3 is sequentially provided with an air suction chamber 4, a liquid suction chamber 5, a mixing throat 6, a pressurized foam chamber 7, an enhanced foam production chamber 8 and a speed-increasing outlet. flow chamber9. Wherein, the swirl nozzle 2 is screwed into the suction chamber 4 in the jet foaming cylinder 3 through threads, and the cavity of the suction chamber 4 is a tapered structure, and its contraction angle α 1 =45°, the suction chamber 4 is provided with an oblique suction hole 10; the cavity of the liquid suction chamber 5 is a tapered structure, and its contraction angle α ...

Embodiment 3

[0020] Example 3: Such as figure 1 As shown, the rotating jet self-priming short-range enhanced foam generating device used for coal shearer dust suppression in the present invention is mainly composed of a pressure water supply pipe 1, a swirl nozzle 2 and a jet foaming cylinder 3. The pressure water The supply pipe 1 is connected with the swirl nozzle 2, and the jet foaming cylinder body 3 is sequentially provided with an air suction chamber 4, a liquid suction chamber 5, a mixing throat 6, a pressurized foam chamber 7, an enhanced foam production chamber 8 and a speed-increasing outlet. flow chamber9. Wherein, the swirl nozzle 2 is screwed into the suction chamber 4 in the jet foaming cylinder 3 through threads, and the cavity of the suction chamber 4 is a tapered structure, and its contraction angle α 1 =60°, the suction chamber 4 is provided with an oblique suction hole 10; the cavity of the liquid suction chamber 5 is a tapered structure, and its contraction angle α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com