Anti-freezing and plugging system of high-pressure gas production pipeline in condensate gas field

A high-pressure gas and pipeline technology, applied in pipeline heating/cooling, mining fluid, earthwork drilling and mining, etc., can solve problems such as large environmental impact, high requirements, and prevention of pipeline freezing and blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

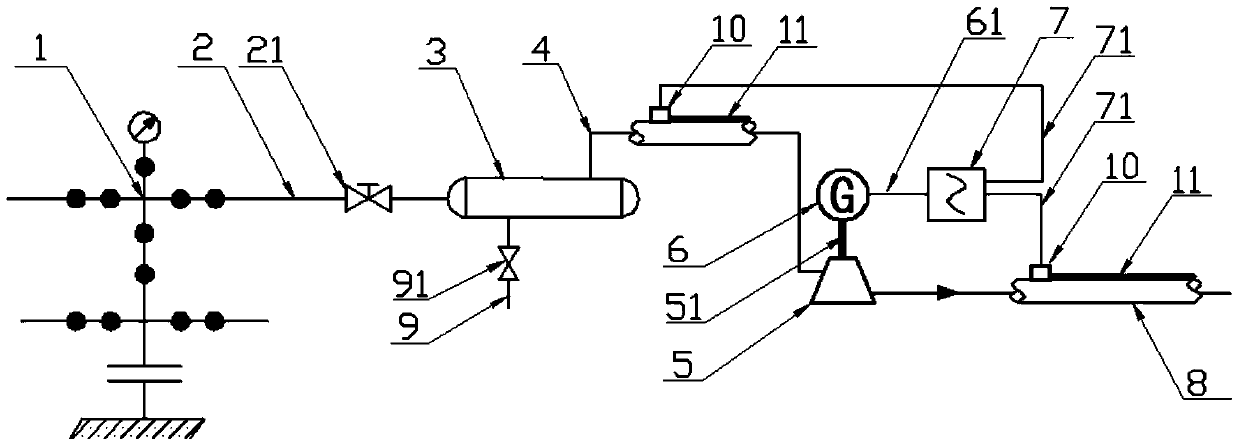

[0013] Such as figure 1 As shown, the anti-freezing and blocking system of the high-pressure gas production pipeline in the condensate gas field provided by the present invention includes a gas well collection tree 1, a horizontal separator 3, a scroll-type high-pressure gas expander 5, a power junction box 10, and a pipeline electric heating cable 11 , generator 6 and transformer 7, the gas well collection tree 1 communicates with the horizontal separator 3 through the gas outlet pipeline 2, the bottom of the horizontal separator 3 is equipped with a sewage pipeline 9, and the horizontal separator 3 is provided with an outlet pipeline 4 through its top It communicates with one end of the scroll-type high-pressure gas expander 5, and the other end of the scroll-type high-pressure gas expander 5 is provided with a gas pipeline 8, and the outlet pipeline 4 and the gas pipeline 8 are provided with a power junction box 10 and a pipeline power supply. The heating cable 11, the vort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com