Fixed alloy gas roasting device

A baking device and stationary technology, applied in the field of stationary alloy gas baking devices, can solve the problems of excess capacity, increase in gas content, temperature drop in molten steel, etc., to reduce personal injury or equipment damage accidents, save gas energy, Highly flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

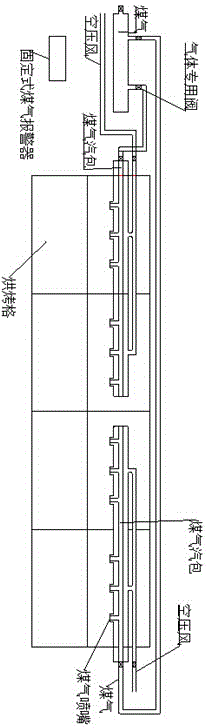

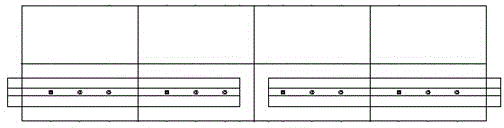

[0012] see Figure 1-Figure 2 , In the embodiment of the present invention, a fixed alloy gas roasting device.

[0013] Equipment before improvement: external gas pipe

[0014] An oxygen pipe with a length of about 2m and a diameter of 15mm, point out the gas with a diameter of 2-3mm at intervals of 25cm in the length direction of the front end, a total of 6 gas holes, 4 alloy warehouses use 6 gas holes, and the rear end of the oxygen pipe is connected to the The gas hose is connected. When in use, the gas hose needs to be placed at the bottom of the silo and baked across the silo. Due to the small space of the oxygen pipe and the small flame strength, it cannot meet the baking temperature and the gas pressure is unstable. Turning off the flame during the roasting process poses a safety hazard.

[0015] Improved equipment: gas nozzle built-in

[0016] There are 2 gas drums with a diameter of 150mm and a length of 2100mm built in the alloy silo. Each gas drum supplies 2 baki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com