Entire-tire gasification device and method for waste tires

A technology for gasification device and waste tires, which is applied in gasification process, fixed bed gasification, manufacture of combustible gas, etc., can solve the problems of difficult operation, high energy consumption, poor operation flexibility, etc., and achieves simple and economical equipment structure. Effective and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

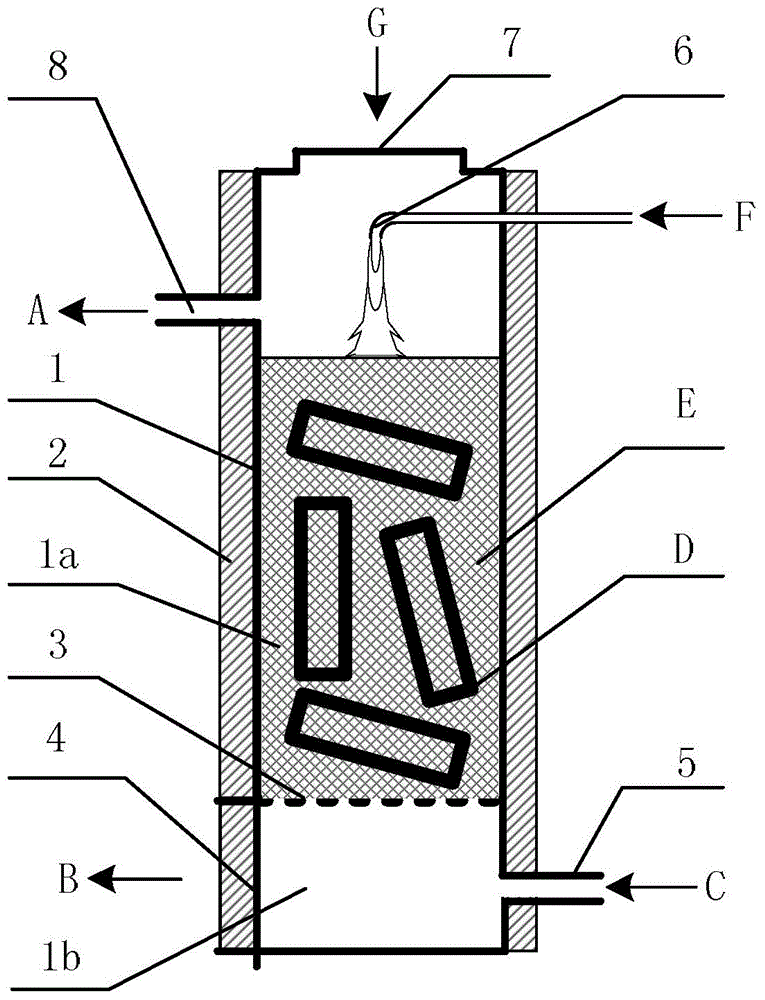

[0023] The gasification device schematic diagram of the present invention is as figure 1 Shown:

[0024] 1) The gasification furnace body 1 of the device is made of carbon steel, and the upper and lower parts are respectively welded with flat heads. The lower part of the gasification furnace body 1 is equipped with a porous grate 3, which is made of cast iron; the porous grate 3 is arranged at the lower part of the gasification furnace body 1. Occupying 1 / 4 of the height of the gasification furnace body, the gasification furnace body 1 is divided into two parts: the upper gasification chamber 1a and the lower ash box 1b. An opening is set on the left side of 1b as the ash outlet 4;

[0025] 2) A gasification agent inlet 5 is provided on the lower right side of the ash box 1b, a plasma ignition device 6 is provided on the upper side of the gasification chamber 1a, and a gas outlet 8 is installed on the other side of the upper part of the gasification chamber 1a, and the outlet...

Embodiment 2

[0030] As in the waste tire and biomass co-gasification device of Example 1, the mass ratio of waste tires in the mixed raw materials is 40%, the waste tires are Bridgestone car tires with a size of 215 / 70R15, and the biomass is rice husks with a length of 1 cm. ; The ignition fuel F is natural gas; the oxygen-enriched air is used as the gasification agent C, the oxygen content in the oxygen-enriched air is 50%, and the oxygen excess coefficient is 0.35; the gasification temperature in the furnace is maintained at 850°C; the gas A produced has a low calorific value 7MJ / m 3 , The gasification is completed in about 2.5 hours. After completion, the quality of non-steel wire solid ash is 12% of the gasification raw material quality (excluding steel wire), and the ash quality is less.

Embodiment 3

[0032] As in the waste tire and biomass co-gasification device in Example 1, the mass ratio of waste tires in the mixed raw materials is 50%, the waste tires are Pirelli truck tires with a size of 295 / 80R22.5, and the biomass is 3 cm in length. Fuel; the ignition fuel F is acetylene; oxygen is used as the gasification agent C, and the oxygen excess coefficient is 0.30; the gasification temperature in the furnace is maintained at 900°C; the low calorific value of the produced gas A is 10MJ / m 3 , the gasification is completed in about 2 hours. After completion, the quality of non-steel wire solid ash is 10% of the gasification raw material quality (excluding steel wire), and the ash quality is less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com