Strand pelletizing device and method for ultra-high fluidity thermoplastic resin

A thermoplastic resin and molding device technology, which is used in the field of drying, cooling, and high-flow resin strands, can solve the problems of complicated operation, pulling strands, insufficient toughness, etc., and achieve uniform pelletizing particles, less fine dust, and appearance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The apparatus and method for strand granulation and molding of ultra-high fluidity thermoplastic resin disclosed in the present invention will be further described below in conjunction with specific embodiments.

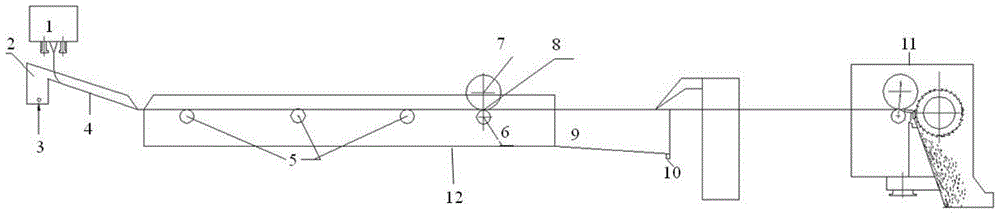

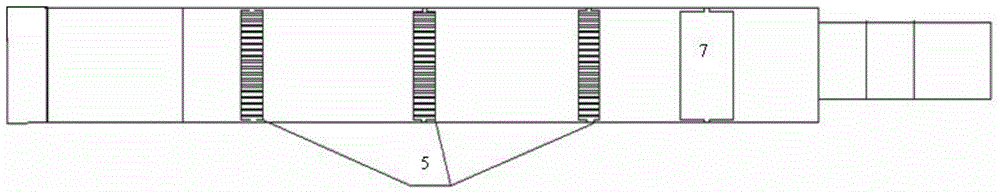

[0020] The strand granulation molding device for ultra-high fluidity thermoplastic resin includes a die head 1, an inclined water tank is provided under the die head 1, and a deflector 4 is arranged on the inclined water tank, which is connected with the water inlet bucket 2. The inclination angle of the deflector 4 is 5°-30°, the water inlet 2 is provided with a water inlet 3 water inlet valve, the ultra-high fluidity thermoplastic resin melt flows out vertically from the die head 1, and falls on the deflector 4 of the inclined water tank. The melt index of the ultra-high fluidity thermoplastic resin is greater than or equal to 200g / 10min, especially greater than or equal to 400g / 10min. The water flow enters the guide plate 4 from bottom to top and flows out f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com