Non-silicon grease type mold release agent for special-shaped rubber tube

A release agent and rubber technology, which is applied in the field of rubber hose molding and processing for automobiles, can solve the problems of rubber quality and life-span adverse effects, and achieve the effects of excellent isolation effect, easy cleaning, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 prepares polyether surfactant

[0040] Raw materials (parts by weight, 1kg per part by weight, the same below):

[0041] The weight of synthetic polyol polyoxyethylene polyoxypropylene ether A consists of:

[0042] Pentaerythritol: 50 parts; Ethylene oxide: 450 parts; Propylene oxide: 500 parts.

[0043] The weight of synthetic polyol polyoxyethylene polyoxypropylene ether B consists of:

[0044] Pentaerythritol: 50 parts; Ethylene oxide: 120 parts; Propylene oxide: 830 parts.

[0045] The weight of synthetic polyol polyoxyethylene polyoxypropylene ether C consists of:

[0046] Pentaerythritol: 20 parts; Ethylene oxide: 130 parts; Propylene oxide: 850 parts.

[0047] The preparation process of each of the above polyol polyoxyethylene polyoxypropylene ethers is as follows: add polyol and potassium hydroxide according to the weight composition in a high-pressure stainless steel kettle, mix and heat up to 60-80°C, and then add ethylene oxide and ring Prop...

Embodiment 2

[0049] Embodiment 2 Preparation of non-silicone grease type mold release agent for special-shaped rubber tube

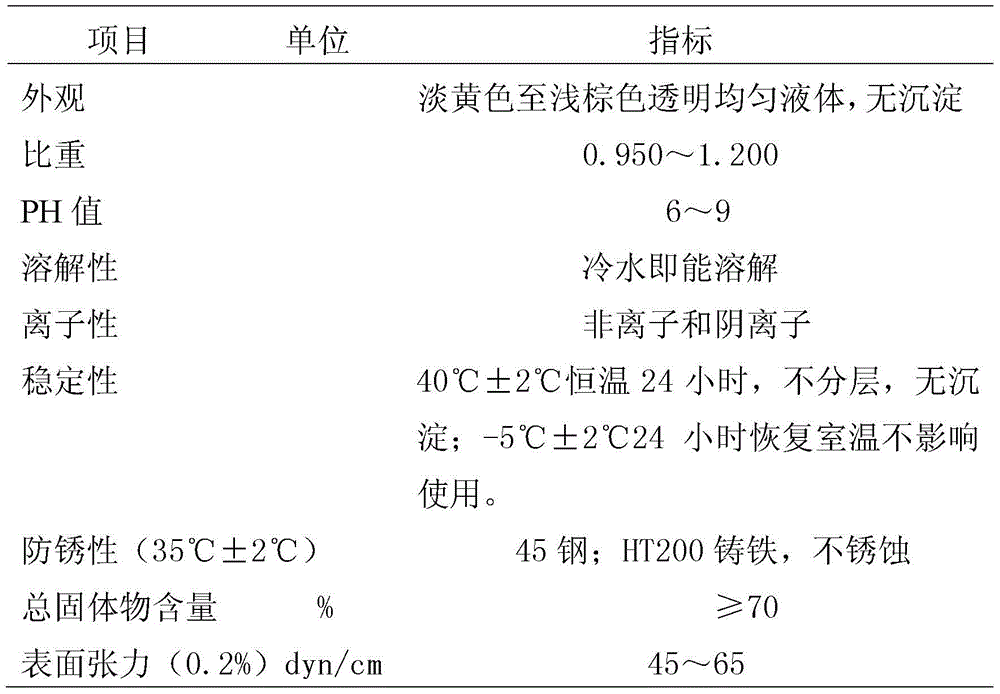

[0050] Using the three polyol polyoxyethylene polyoxypropylene ethers obtained in Example 1, the raw materials were mixed uniformly according to the formulas 1 and 2 in Table 2, respectively, to obtain the silicone grease-free mold release agent for special-shaped rubber tubes of the present invention.

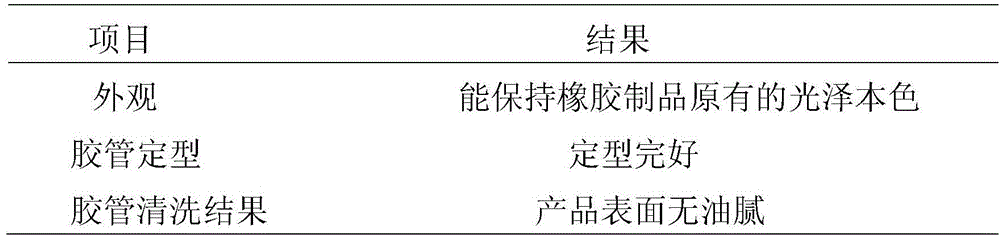

[0051]In the production line of rubber hose forming, especially the production line of rubber hose forming processing for automobiles, use cloth, brush or spray gun to clean the surface of metal film tools with 90 and 120 degrees and diameters of 1cm, 2cm, 3cm and 5cm respectively, and directly clean them according to the above The special-shaped rubber tubes obtained in formulas 1 and 2 were painted on the surface of the core type with a silicone-free mold release agent, and then the unshaped EPDM rubber and nitrile rubber tubes were respectively inserted into the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com