Suspension type vibration-proof structure

An anti-vibration structure and suspension technology, which is applied in the direction of anti-vibration, building components, etc., can solve problems such as difficult to realize, and achieve the effects of low power consumption, high efficiency, and reduced seismic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

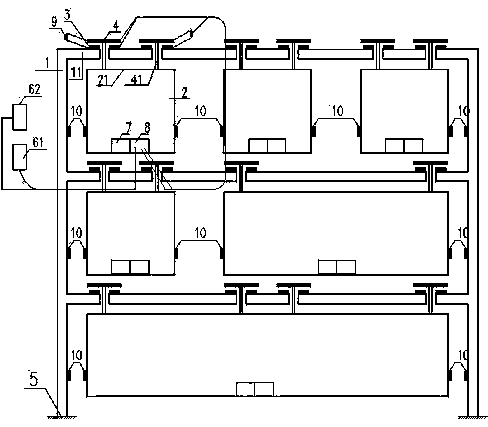

[0025] Embodiment 1: as figure 1 Shown is the principle diagram of the repulsive suspension structure of the present invention.

[0026] In this embodiment, the substructure magnets (4) and magnets (3) adopt electromagnets, which means that several substructures (2) are made in the engineering structure (1), above the top (21) of the substructure (2) A substructure magnet (4) is formed, and a magnet (3) is formed above or below the structural beam or plate (11) of the engineering structure (1) corresponding to the substructure magnet (4); and the engineering structure (1) and A control device is formed between the substructures (2). Wherein, the substructure magnet (4) is connected to the top (21) of the substructure (2) through a connecting rod (41) passing through the structural beam or plate (11), and placed above the magnet (3) ; The magnet (3) is fabricated above the structural beam or plate (11); and the substructure magnet (4) and the magnet (3) have the same electrom...

Embodiment 2

[0032] Embodiment 2: as image 3 Shown is the principle diagram of another embodiment of the repulsive suspension structure of the present invention.

[0033] In this embodiment, the substructure magnets (4) and magnets (3) adopt electromagnets, which means that several substructures (2) are made in the engineering structure (1), above the top (21) of the substructure (2) A substructure magnet (4) is formed, and a magnet (3) is formed above or below the structural beam or plate (11) of the engineering structure (1) corresponding to the substructure magnet (4); and the engineering structure (1) and A control device is formed between the substructures (2). Among them, the substructure magnet (4) is connected with the top (21) of the substructure (2) through the connecting rod (41), and placed above the magnet (3), and the magnet (3) is connected through the connecting piece (31 ) is connected to the underside of the structural beam or plate (11); and the substructure magnet (4...

Embodiment 3

[0034] Embodiment 3, as Figure 4 Shown is the principle diagram of the suction type suspension structure of the present invention.

[0035]In this embodiment, the substructure magnets (4) and magnets (3) adopt electromagnets, which means that several substructures (2) are made in the engineering structure (1), above the top (21) of the substructure (2) A substructure magnet (4) is formed, and a magnet (3) is formed above or below the structural beam or plate (11) of the engineering structure (1) corresponding to the substructure magnet (4); and the engineering structure (1) and A control device is formed between the substructures (2). Among them, the substructure magnet (4) is directly fabricated on the top (21) of the substructure (2) and placed under the magnet (3), and the magnet (3) is also directly fabricated on the structural beam or plate (11 ) below; and the electromagnetic polarities of the opposite faces of the substructure magnet (4) and magnet (3) are opposite w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com