Pipe punching machine

A technology for punching machines and pipes, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc. It can solve the problems of difficult discharge of waste materials, achieve high production efficiency, reduce labor intensity of workers, and improve punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Although the present invention has been described with reference to specific embodiments, those skilled in the art will be able to make obvious modifications and modifications to the present invention after reading the above description without departing from the intent and essence of the present invention. The present invention intends to include such modifications and modifications within the scope of the claims.

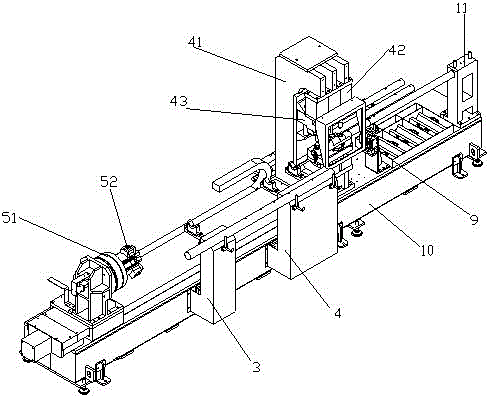

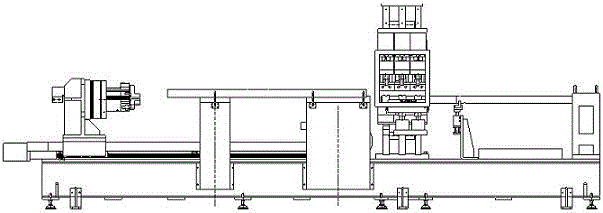

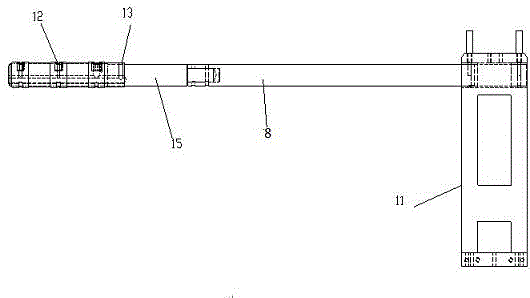

[0034] combine Figure 1~Figure 8 , the pipe punching machine of the present invention includes a base 10 and a mounting base 41 installed on the base 10, a punching device is installed on the mounting base 41, and it is characterized in that the base 10 is equipped with a A workpiece clamping device and a workpiece lifting device that cooperate with each other, the workpiece lifting device is located between the punching device and the workpiece clamping device, and the punching device includes a mounting frame 11 and an oil Cylinder one 42, the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com