Oxide film transistor and manufacturing method thereof

A technology of oxide thin film and manufacturing method, which is applied in transistors, semiconductor/solid-state device manufacturing, electric solid-state devices and other directions, can solve problems such as the influence of oxide thin-film transistor characteristics, the normal use of thin-film transistors, and the damage to the back channel, etc. Save production time, save production cost, and improve the effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

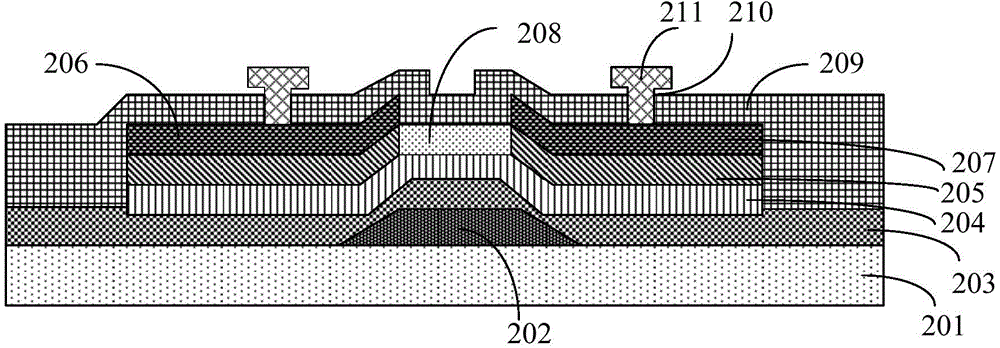

[0031] refer to figure 1 , figure 1 It is a schematic flowchart of an embodiment of the method for fabricating an oxide thin film transistor of the present invention. The manufacturing method of the present embodiment comprises the following steps:

[0032] 101: Form a gate, a gate insulating layer, and an oxide semiconductor film layer sequentially on a first substrate.

[0033] Specifically, firstly, a metal film layer is formed on the first substrate by deposition, the metal film layer is exposed through a first photomask, and the metal film layer is etched to form a gate. Among them, the first photomask is an ordinary photomask that can only etch one layer.

[0034] Wherein, the first substrate includes a glass substrate and a quartz substrate, and may also be other substrates in other implementation manners, which is not limited here.

[0035] The metal film layer includes at least one of aluminum Al, molybdenum Mo, copper Cu, and silver Ag, and may be other metals in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com