Prestressed modulus type duct piece for whole-ring reinforcing in tunnel and construction method

A prestressed, in-tunnel technology, used in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of inability to share the internal force of the original segment, damage the bearing capacity of the original segment, and affect the normal operation of the vehicle. The effect of reducing structural deformation and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

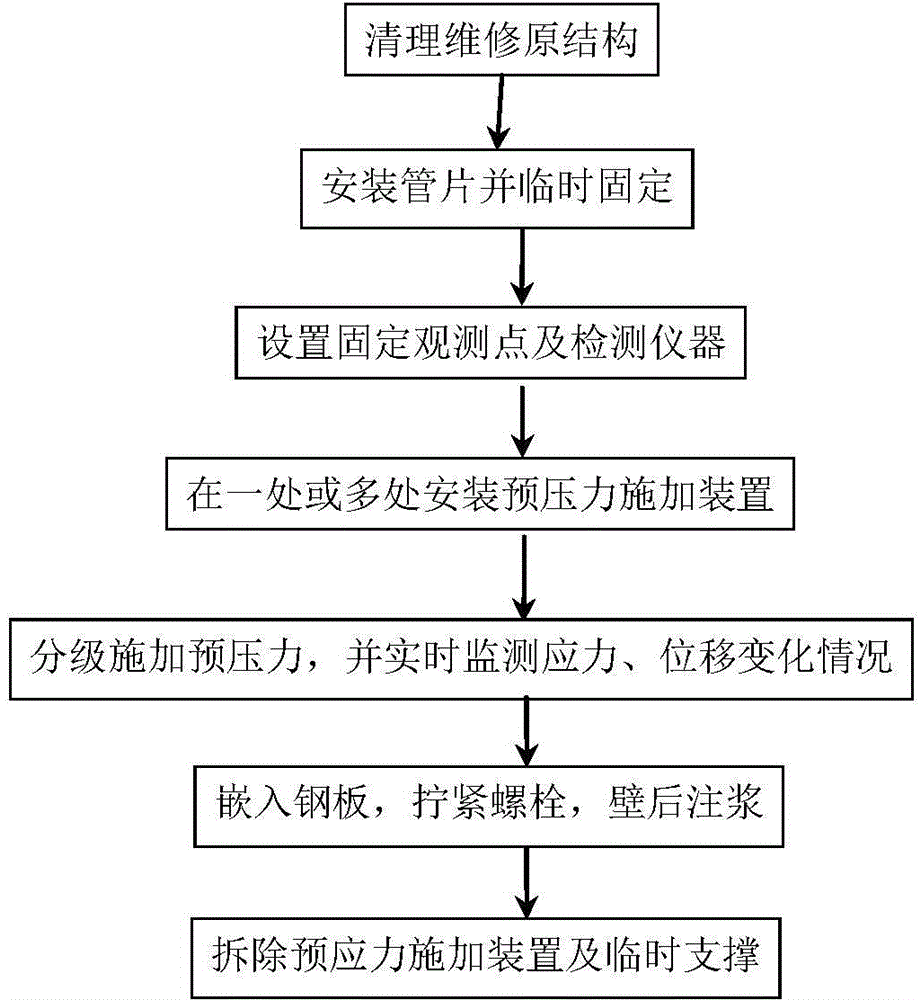

[0043] The present invention is described in detail below in conjunction with accompanying drawing:

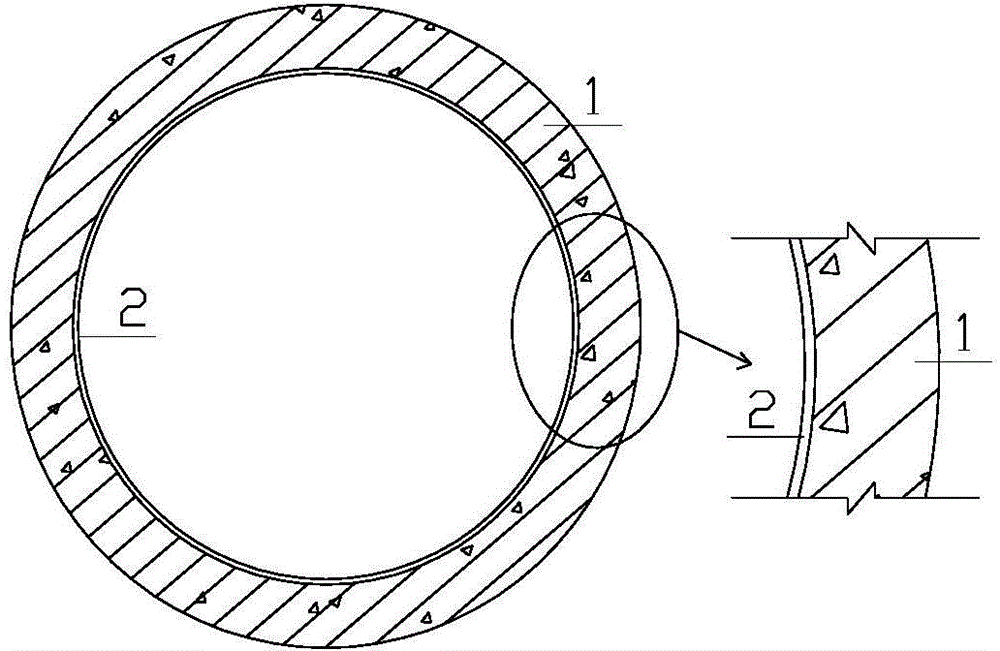

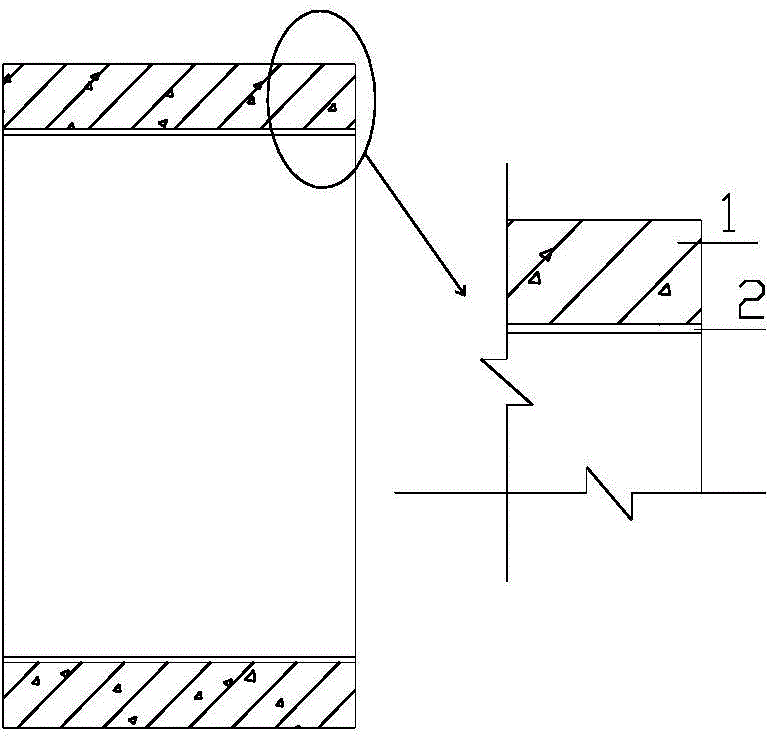

[0044] Such as Figure 3(a) - Figure 13 As shown, a prestressed modulus segment used for the whole ring reinforcement of the tunnel includes an arc-shaped segment 3-9, and the inner surface or / and outer surface of the arc-shaped segment are provided with a plurality of parallel longitudinal ribs 3-2, and adjacent longitudinal ribs are connected by transverse ribs 3-1, and the longitudinal ribs 3-2 and transverse ribs 3-1 protrude from the inner surface or / and outer surface of the segment. The top and bottom surfaces of the segment are provided with a pre-pressure applying device installation groove 3-5, and bolt holes 3-3 and grouting holes 3-4 are installed on the segment; this segment structure avoids a large reduction in tunnel Inner building limits; the structure has preload, actively bears the external load, changes the stress state of the original segment, and reduces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com