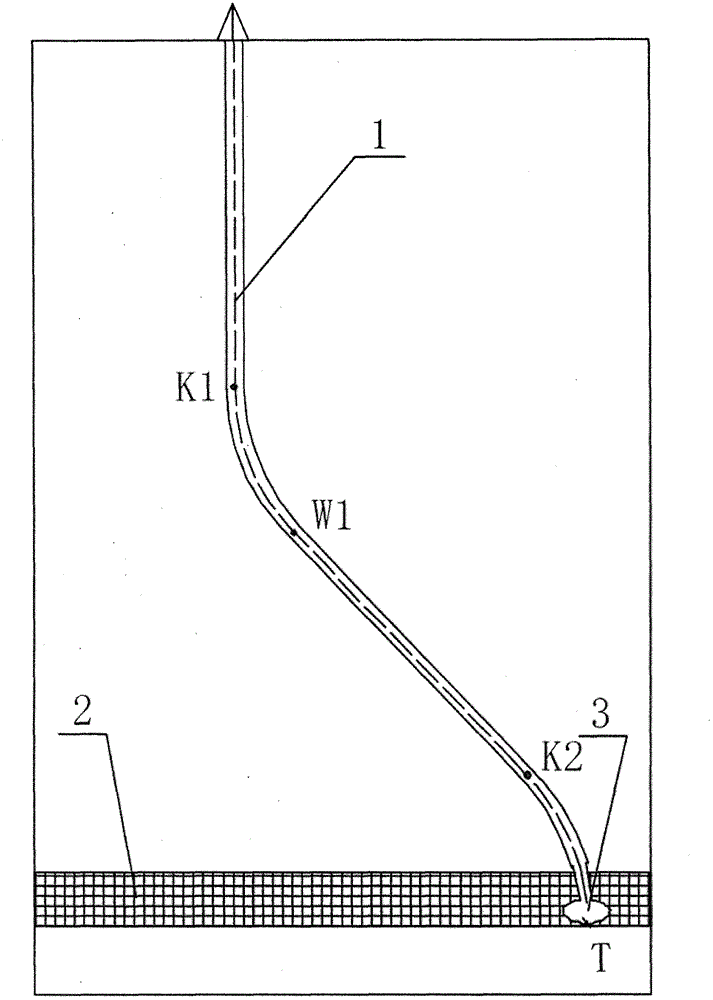

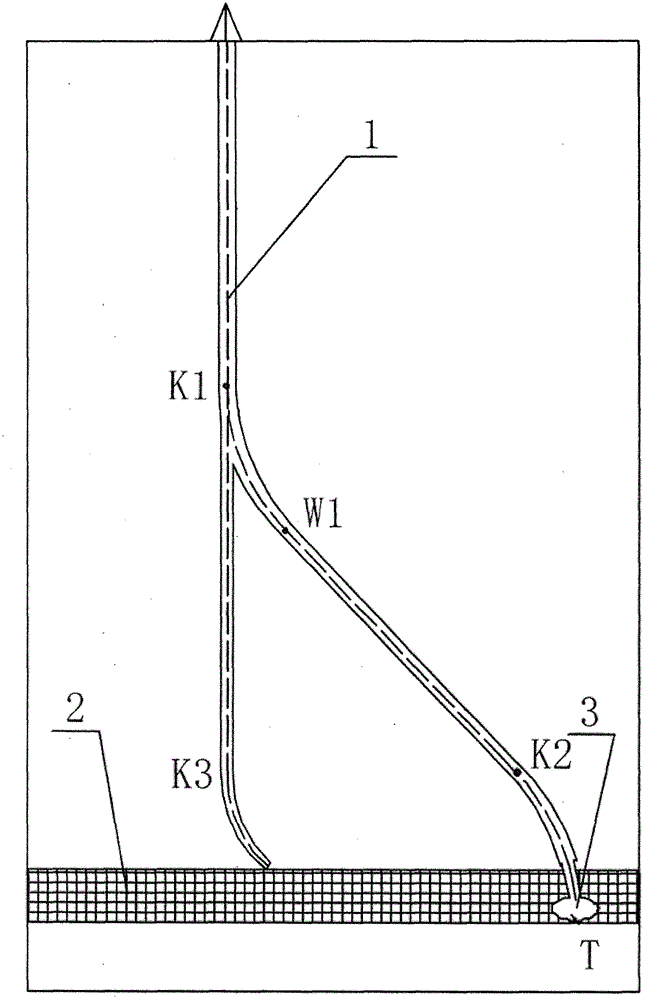

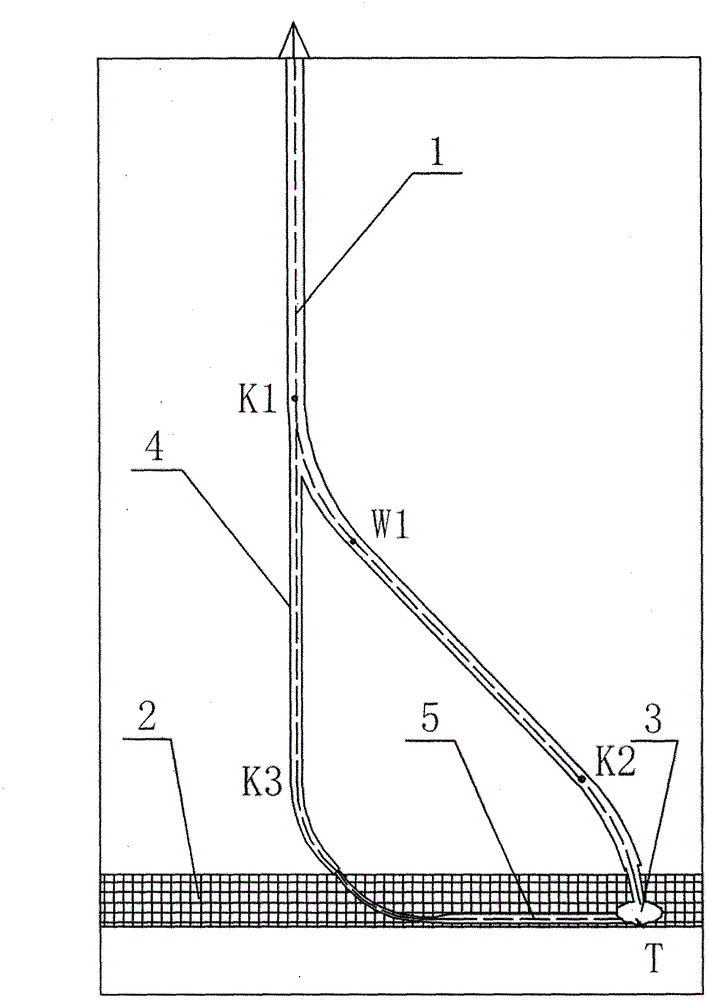

Single borehole multilateral directional butted well salt mining method

A technology of docking wells and single drilling holes, which is applied in earth-moving drilling, surface mining, underground mining, etc., can solve the problems of difficulty in drilling and mining in salt mines and high drilling costs, and is conducive to stope pressure management and accurate docking. The effect of improving efficiency, directional design and simplification of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] see Figure 5 , in the embodiment of the present invention, a single drilling branch directional butt joint well salt mining method, taking the Dongying Delta Salt Mine in Shandong as an example, the mining depth of the salt mine is about 4000 meters, and the directional horizontal well connection mining method is proposed. There are 2 wells in each group, the total drilling depth of the well group reaches about 8,500 meters, and the total cost of the well group reaches more than 25 million yuan. Adopting the single-drilling branch butt-joint communication mode of the present invention will reduce the drilling footage of each well group by more than 3,500 meters, and save about 70% of the well construction cost. Specific steps are as follows:

[0033] Step 1: First, use a Φ444.5mm drill bit to open the hole, drill to a depth of 400 meters, and run into a Φ339.7mm casing for about 400 meters of cementing; then use a Φ311.1mm drill bit to drill to about 3480 meters, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com