Novel environment-friendly composite slurry and preparation method thereof

A kind of composite slurry and environment-friendly technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of high surface tension, rigidity, poor elasticity, etc., and achieve good adhesion, low cost, and good desizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

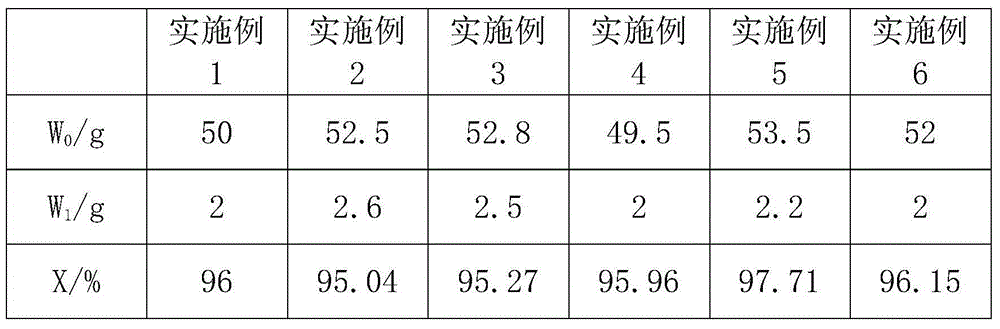

Examples

Embodiment 1

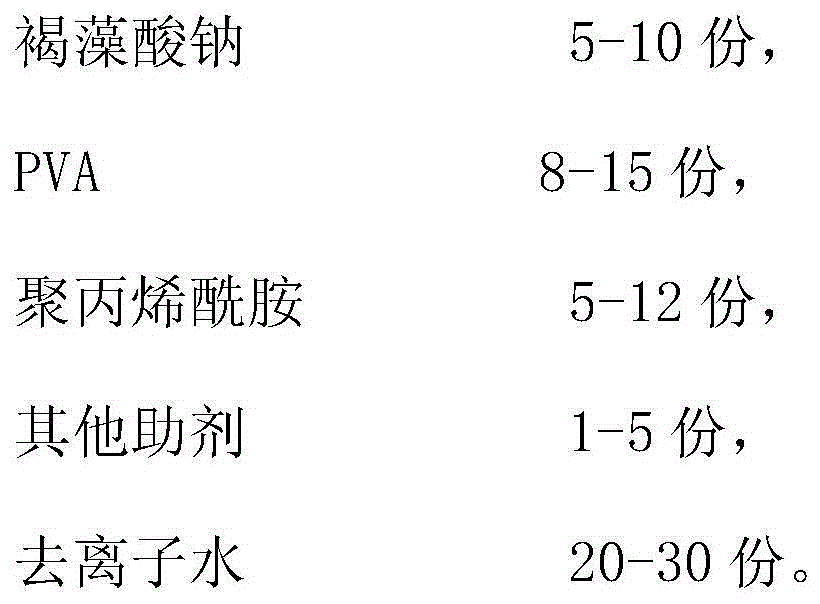

[0026] A novel environment-friendly composite slurry, in parts by weight, comprises the following components:

[0027] 5 parts of sodium alginate, 8 parts of PVA, 5 parts of polyacrylamide, 1 part of other additives, 20 parts of deionized water.

[0028] Its preparation method comprises the following steps:

[0029] (1) The pulp kettle is cleaned with deionized water, and dried for later use;

[0030] (2) Add 20 parts of deionized water and 5 parts of sodium alginate into the slurry kettle, start the mixer, slowly raise the temperature to 60°C, and stir for 30 minutes at a speed of 500 rpm;

[0031] (3) Add 1 part of other additives, continue to stir, and adjust its pH to 5, cool down to 40°C, slowly add 8 parts of PVA and 5 parts of polyacrylamide, stir while adding, and get a new type of environmentally friendly compound after stirring for 50 minutes. slurry.

Embodiment 2

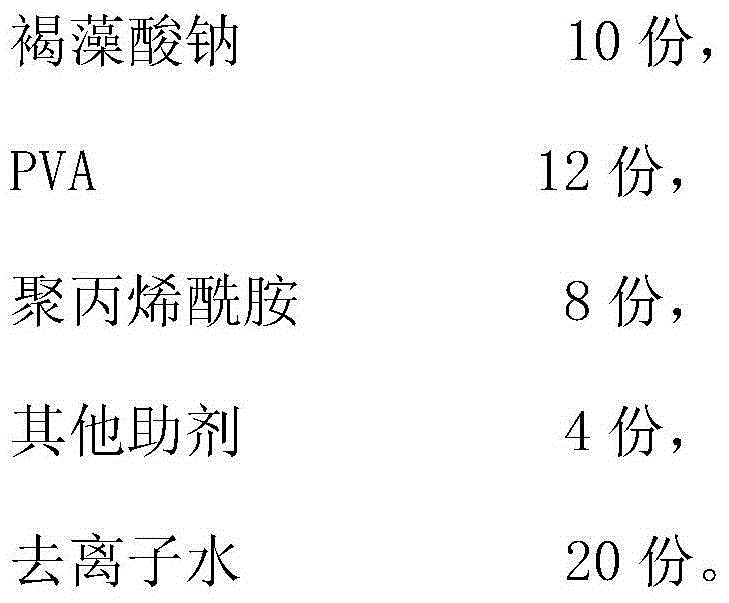

[0033] A novel environment-friendly composite slurry, in parts by weight, comprises the following components:

[0034] 10 parts of sodium alginate, 15 parts of PVA, 12 parts of polyacrylamide, 5 parts of other additives, 30 parts of deionized water.

[0035] Its preparation method comprises the following steps:

[0036] (1) The pulp kettle is cleaned with deionized water, and dried for later use;

[0037] (2) Add 30 parts of deionized water and 10 parts of sodium alginate into the slurry kettle, start the mixer, slowly raise the temperature to 70°C, and stir for 60 minutes at a speed of 800 rpm;

[0038] (3) Add 5 parts of other additives, continue stirring, adjust the pH to 7, cool down to 50°C, slowly add 15 parts of PVA and 12 parts of polyacrylamide, stir while adding, and get a new type of environmentally friendly compound after stirring for 100 minutes. slurry.

Embodiment 3

[0040] A novel environment-friendly composite slurry, in parts by weight, comprises the following components:

[0041] 6 parts of sodium alginate, 9 parts of PVA, 6 parts of polyacrylamide, 2 parts of other additives, 22 parts of deionized water.

[0042] Its preparation method comprises the following steps:

[0043] (1) The pulp kettle is cleaned with deionized water, and dried for later use;

[0044] (2) Add 22 parts of deionized water and 6 parts of sodium alginate into the slurry kettle, start the mixer, slowly raise the temperature to 62°C, and stir for 35 minutes at a speed of 550 rpm;

[0045] (3) Add 2 parts of other additives, continue to stir, adjust the pH to 6, cool down to 42°C, slowly add 9 parts of PVA and 6 parts of polyacrylamide, stir while adding, and get a new type of environmentally friendly compound after stirring for 55 minutes. slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com