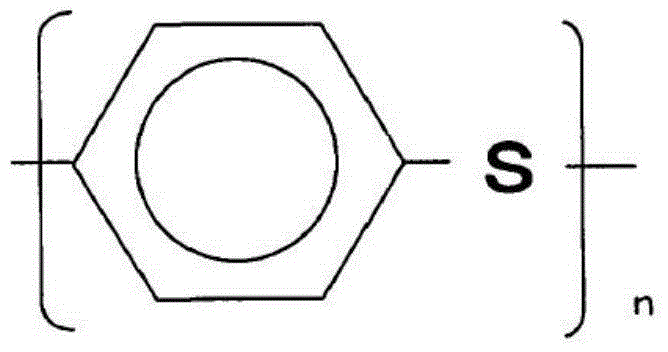

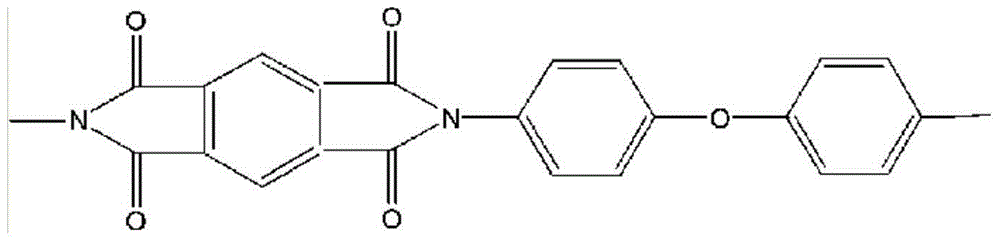

Flame retardant yarn comprising aromatic polymer fiber containing sulfuryl, fabric made of same and preparation method

A technology of aromatic polymers and yarns, applied in fabrics, yarns, textiles, etc., can solve problems such as obvious droplet phenomenon, difficult dyeing, secondary damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

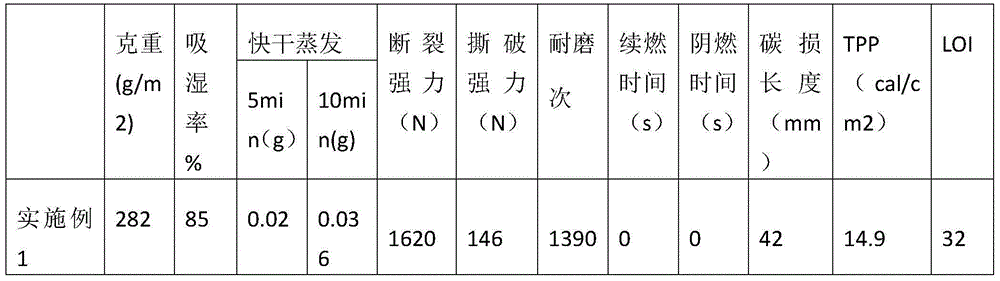

[0170] The fiber weight ratio is: 30% H-PSA fiber, 20% flame-retardant nylon, 35% flame-retardant viscose, 15% aramid 1414, the four kinds of fibers pass through the clear cotton blended strip prepared by conventional cotton spinning system equipment, and then pass through the ring Spinning spinning machine spins into 24s spun yarn, which is made into flame-retardant 24s / 2 ply yarns as weaving warp yarns. Using the same similar process and blending ratio, 20s / 2 is used as weaving weft yarn. The natural color twill fabric with a weight of 267g / m2 is produced by air-jet weaving. The washed fabric is spray dyed in the overflow dyeing vat. The resulting colored finished fabric has a gram weight of 282g / m2.

Embodiment 2

[0172] The fiber weight ratio is: 25% H-PSA fiber, 30% flame-retardant nylon, 35% flame-retardant viscose, 10% aramid 1414, the four kinds of fibers are passed through the clear cotton blended strip prepared by conventional cotton spinning system equipment, and then passed through compact The spinning frame spun into 30s spun yarn, which is combined by the plying machine to make a flame-retardant 30s / 2 ply yarn as the weaving warp. Using the same similar process and blending ratio to make 28s / 2 as weaving weft yarn. A natural twill fabric with a weight of 207g / m2 is produced through a shuttle loom. The washed fabric is spray dyed in the overflow dyeing vat. The resulting colored finished fabric has a gram weight of 212 g / m2.

Embodiment 3

[0174] The fiber weight ratio is: 20% H-PSA fiber, 35% flame-retardant nylon, 40% flame-retardant viscose, 5% aramid 1414, the four kinds of fibers pass through the clear cotton blended strip prepared by conventional cotton spinning system equipment, and then pass through compact The spinning frame spun into 32s spun yarn, which is combined with the yarn by the plying machine to make a flame-retardant 32s / 2 ply yarn as the weaving warp yarn. The plain weave fabric of 195g / m2 is produced by weaving a shuttle loom. The washed fabric is spray dyed in the overflow dyeing vat. The resulting colored finished fabric has a weight of 202g / m2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com