Alloy refining agent and preparation method thereof

A refiner and alloy technology, which is applied in the field of alloy refiner and its preparation to achieve the effect of inhibiting more and more coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

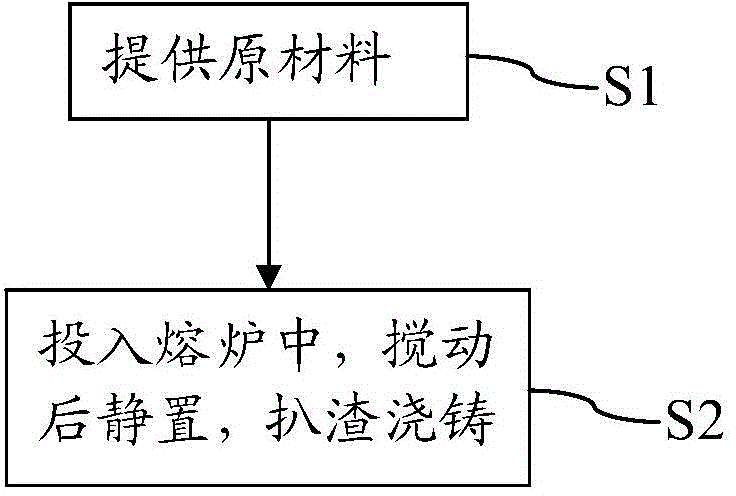

[0021] Such as figure 1 As shown, for the above-mentioned alloy refiner for the refinement of aluminum-titanium-boron or aluminum-titanium-carbon master alloy, the present invention provides a preparation method of the alloy refiner, which comprises the following steps:

[0022] S1. In terms of weight percentage, according to 80% to 95% of aluminum titanium boron or aluminum titanium carbon master alloy: 0.1% to 10% of lanthanum cerium rare earth metal, 1% to 30% of phosphorus metal, and added to aluminum titanium boron Or Al-Ti-C master alloy to form a mixture; wherein, Al-Ti-B or Al-Ti-C master alloy includes: titanium 1-5.5%, boron 0.1-1%, carbon 0.2-1%; lanthanum-cerium rare earth metal includes: lanthanum 23 ~39%, cerium 45~55%, neodymium 8~20%;

[0023] S2. After raising the temperature of the furnace to 720-900°C, add the mixture into the aluminum-titanium-boron or aluminum-titanium-carbon master alloy melting furnace, and after stirring, stand still for 10-30 minutes ...

Embodiment 1

[0030] In terms of weight percentage, it is provided as 80% aluminum titanium boron or aluminum titanium carbon master alloy, 0.1% lanthanum cerium rare earth metal, and 1% phosphorus metal. And add it to aluminum titanium boron or aluminum titanium carbon master alloy to form a mixture. Among them, lanthanum and cerium rare earth metals include: 23% lanthanum, 45% cerium, and 8% neodymium.

[0031] After heating the furnace to 900°C, add the mixture into the aluminum-titanium-boron or aluminum-titanium-carbon master alloy melting furnace, stir it, let it stand for 10-30 minutes for slag removal, and directly cast it into an ingot or prepare it into a wire rod.

Embodiment 2

[0033] In terms of weight percentage, it is provided as 95% aluminum titanium boron or aluminum titanium carbon master alloy, 10% lanthanum cerium rare earth metal, and 30% phosphorus metal. And add it to aluminum titanium boron or aluminum titanium carbon master alloy to form a mixture. Among them, lanthanum and cerium rare earth metals include: 39% lanthanum, 55% cerium, and 20% neodymium.

[0034] After heating the furnace to 720°C, add the mixture into the aluminum-titanium-boron or aluminum-titanium-carbon master alloy melting furnace, stir it, let it stand for 10-30 minutes to remove slag, and directly cast it into an ingot or prepare it into a wire rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com