A kind of double-sided adhesive tape for lithium battery and preparation method thereof

A double-sided tape, lithium battery technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of reducing the service life of lithium batteries, reducing the performance of lithium batteries, affecting the performance of lithium batteries, etc. , to achieve the effect of improving service life, good resistance to lithium battery electrolyte performance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A double-sided adhesive tape for lithium batteries of the present invention comprises a first sealing hot-melt pressure-sensitive adhesive layer, a base film layer, a second sealing hot-melt pressure-sensitive adhesive layer, and a non-tacky sealing adhesive layer at normal temperature sequentially connected from top to bottom And double-sided silicon-free release film layer.

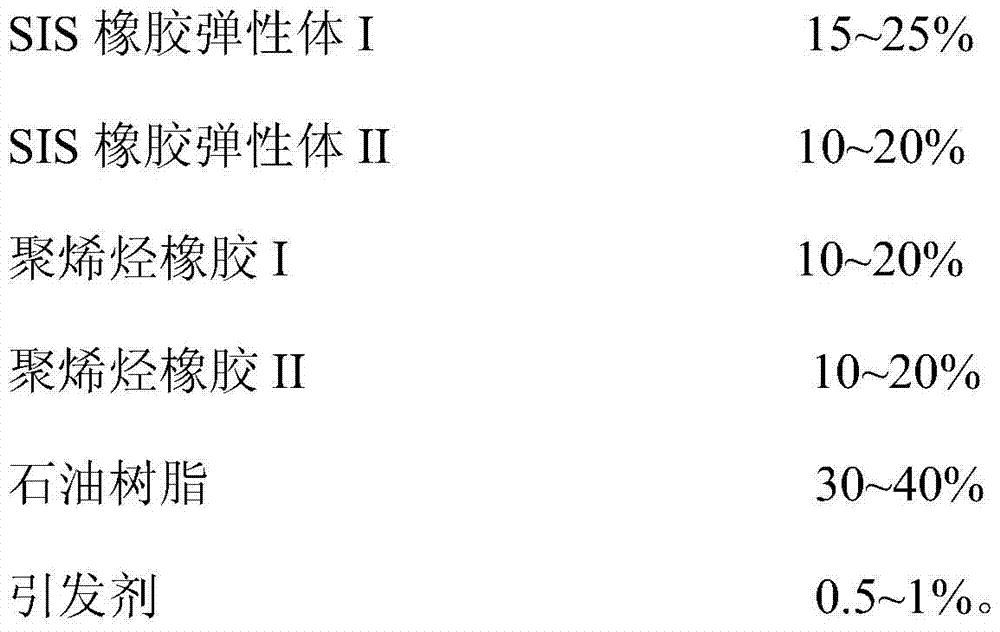

[0046] The first sealing hot-melt pressure-sensitive adhesive layer of the present embodiment includes the following raw materials in mass percentage:

[0047]

[0048]

[0049] The second sealing hot-melt pressure-sensitive adhesive layer of the present embodiment includes the following raw materials in mass percentage:

[0050]

[0051] The normal temperature non-tack sealant layer of the present embodiment comprises the following raw materials in mass percentage:

[0052]

[0053] The base film layer in this embodiment is a PET film layer.

[0054] The thicknesses of the first se...

Embodiment 2

[0066] A double-sided adhesive tape for lithium batteries of the present invention comprises a first sealing hot-melt pressure-sensitive adhesive layer, a base film layer, a second sealing hot-melt pressure-sensitive adhesive layer, and a non-tacky sealing adhesive layer at normal temperature sequentially connected from top to bottom And double-sided silicon-free release film layer.

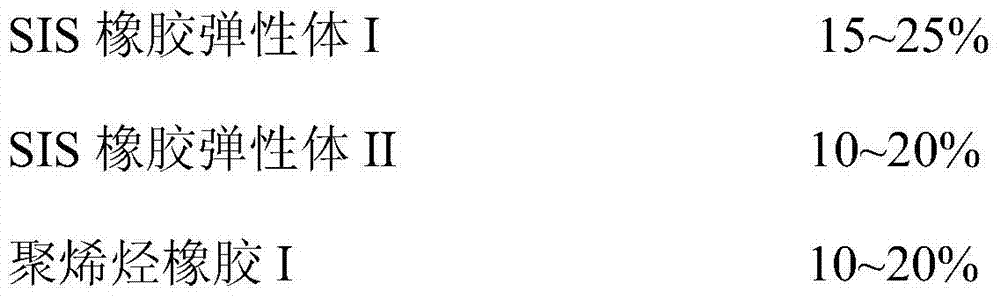

[0067] The first sealing hot-melt pressure-sensitive adhesive layer of the present embodiment includes the following raw materials in mass percentage:

[0068]

[0069] The second sealing hot-melt pressure-sensitive adhesive layer of the present embodiment includes the following raw materials in mass percentage:

[0070]

[0071] The normal temperature non-tack sealant layer of the present embodiment comprises the following raw materials in mass percentage:

[0072]

[0073]

[0074] The base film layer in this embodiment is a PET film layer.

[0075] The thicknesses of the first se...

Embodiment 3

[0087] A double-sided adhesive tape for lithium batteries of the present invention comprises a first sealing hot-melt pressure-sensitive adhesive layer, a base film layer, a second sealing hot-melt pressure-sensitive adhesive layer, and a non-tacky sealing adhesive layer at normal temperature sequentially connected from top to bottom And double-sided silicon-free release film layer.

[0088] The first sealing hot-melt pressure-sensitive adhesive layer of the present embodiment includes the following raw materials in mass percentage:

[0089]

[0090] The second sealing hot-melt pressure-sensitive adhesive layer of the present embodiment includes the following raw materials in mass percentage:

[0091]

[0092] The normal temperature non-tack sealant layer of the present embodiment comprises the following raw materials in mass percentage:

[0093]

[0094] The base film layer in this embodiment is a PET film layer.

[0095] The thicknesses of the first sealing hot-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com