A method for producing macroelement water-soluble fertilizer at low cost

A large amount of elements, low-cost technology, applied in the direction of inorganic fertilizers, ammonium salt fertilizers, nitrate fertilizers, etc., can solve the problems of less soluble phosphate production processes, high manufacturing costs, and low investment, and achieve reasonable graded use and transportation The effect of convenience and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

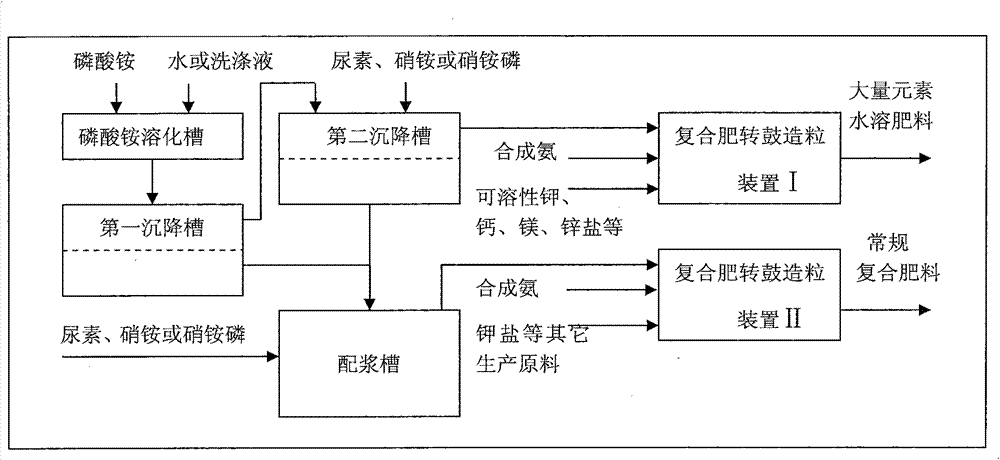

Method used

Image

Examples

Embodiment 1

[0034] "17-18-17" macroelement water-soluble fertilizer (medium element type), supporting 15-23-10 (its formula is: N=10.61%, P 2 o 5 = 46.55% of monoammonium phosphate 165.37kg / t, insufficient P 2 o 5 Provided by the ammonium phosphate in the mixed slurry of the ammonium phosphate slurry II of the first settling tank and the co-dissolving slurry II of the second settling tank during the preparation of the 17-18-17 water-soluble fertilizer; N=32.00%, P 2 o 5 = 4.00% ammonium nitrate 219.68kg / t; K 2 O=50% potassium sulfate 199.65kg / t; N=81.94% synthetic ammonia 38.38kg / t; H 2 SO 4 =98% sulfuric acid 70.38kg / t) preparation of compound fertilizer.

[0035] raw material:

[0036] Monoammonium phosphate: N=10.61%, P 2 o 5 =46.55%, water-soluble matter=81.00%, water-insoluble matter=17.00%, water=2.00%;

[0037] Phosphorous ammonium nitrate: N=32.00%, P 2 o 5 = 4.00%, water-insoluble matter ≤ 0.01%, water = 1.00%;

[0038] Calcium nitrate: N=13%, soluble (calcium+magnes...

Embodiment 2

[0055] "17-17-17" macroelement water-soluble fertilizer (trace element type), supporting 20-18-12 (its formula is: N=10.39%, P 2 o 5 = 48.00% monoammonium phosphate 165.83kg / t, insufficient P 2 o 5 Provided by the ammonium phosphate in the mixed slurry of the ammonium phosphate slurry II of the first settling tank and the co-dissolving slurry II of the second settling tank during the preparation of 17-17-17 water-soluble fertilizer; N=46.00% urea 266.67 kg / t; K 2 O=60% potassium chloride 200.21kg / t; N=81.94% synthetic ammonia 46.33kg / t; H 2 SO 4 =98% sulfuric acid 105.11kg / t) preparation of compound fertilizer.

[0056] raw material:

[0057] Monoammonium phosphate: N=10.39%, P 2 o 5 =48.00%, water-soluble matter=78.79%, water-insoluble matter=19.21%, water=2.00%;

[0058] Urea: N=46.00%, water insoluble ≤0.01%, water=1.00%;

[0059] Zinc sulfate: Zn=35%, water insoluble ≤0.01%, water=1.00%;

[0060] Potassium chloride: K 2 O=60.00%, water insoluble ≤0.01%, water=1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com