Method for treating acid waste water containing arsenic

A treatment method and wastewater technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, low cost, unstable sedimentation, etc. less pollution, good stability, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Treatment of arsenic filter cake waste residue hot acid leaching solution produced in copper concentrate smelting process

[0034] After oxidizing the leaching solution, the ions and their contents in the leaching solution: As(Ⅴ) 10.08g / L, Cu 2+ 5.07g / L, the anion is mainly SO 4 2- , the pH of the solution is about 2.19.

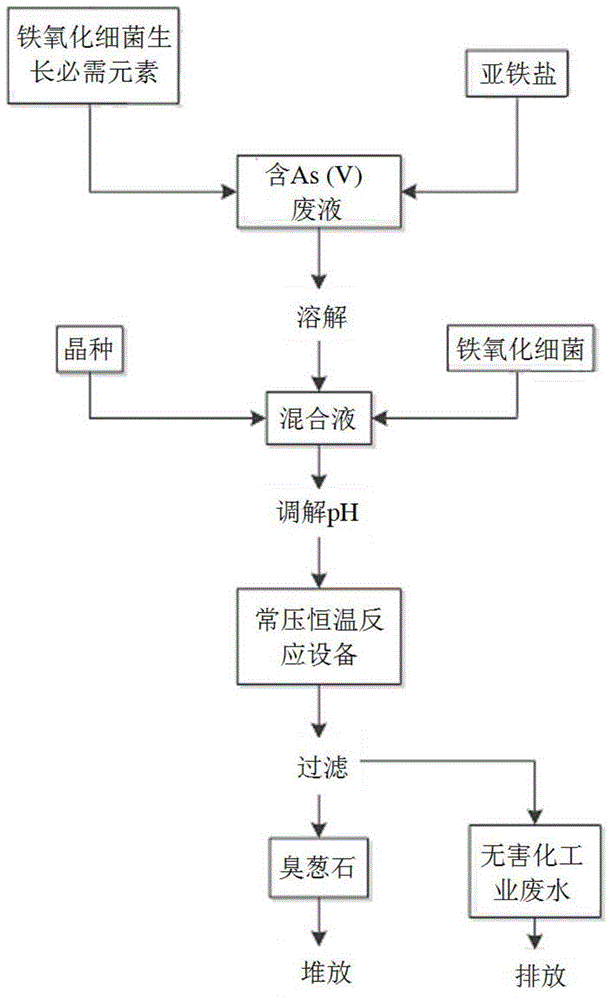

[0035] In this embodiment, the treatment of the above-mentioned arsenic-containing wastewater is carried out by the following method, which specifically includes the following steps (the treatment process is as follows: figure 1 shown):

[0036] (1) Add MgSO to 100 mL of the above-mentioned arsenic-containing wastewater diluted to an As(V) concentration of 3 g / L 4 , KCl, Ca(NO 3 ) 2 , (NH 4 ) 2 SO 4 and K 2 HPO 4 Make into Leathern medium, add 0.02g yeast extract powder, then add 1.668g FeSO 4 x7H 2 O, completely dissolved, so that the molar ratio of iron to arsenic in the solution is 1.5:1, add 2.0g of seed FeAsO 4 ·2H 2 O...

Embodiment 2

[0041] Example 2 Treatment of the bioleaching solution of arsenic-containing gold concentrate

[0042] After oxidizing the leaching solution, the ions and their contents in the leaching solution: As(Ⅴ) 2.21g / L, Fe 3+ 4.26g / L, the anion is mainly SO 4 2- , the pH of the solution is about 1.6.

[0043] In this embodiment, the treatment of the above-mentioned arsenic-containing wastewater is carried out by the following method, which specifically includes the following steps (the treatment process is as follows: figure 1 shown):

[0044] (1) Remove Fe to 100 mL 3+ Add MgSO to the above-mentioned arsenic-containing wastewater 4 , KCl, Ca(NO 3 ) 2 , (NH 4 ) 2 SO 4 and K 2 HPO 4 Prepare 9K medium, add 0.02g yeast extract powder, then add 2.46g FeSO 4 x7H 2 O, completely dissolved, so that the molar ratio of iron to arsenic in the solution is 3:1, and 1.0g of seed FeAsO is added 4 ·2H 2 O, and inoculated with acid-resistant and arsenic-resistant acclimated Thiobacillu...

Embodiment 3

[0048] Example 3 Treatment of Waste Liquid from Zinc Refinery

[0049] Various ions and their contents in the waste liquid of zinc refinery: As 21.35g / L, Zn 1.55g / L, Cu 3.64g / L, Pb 3.72g / L, etc., pH is about 1.0.

[0050] In this embodiment, the treatment of the above-mentioned arsenic-containing wastewater is carried out by the following method, which specifically includes the following steps (the treatment process is as follows: figure 1 shown):

[0051] (1) MgSO was added to 100 mL of the above-mentioned arsenic-containing wastewater that had removed Pb and Cu ions and was diluted to contain As(V) of 3 g / L. 4 , KCl, Ca(NO 3 ) 2 , (NH 4 ) 2 SO 4 and K 2 HPO 4 Make up into Leathern medium, then add 2.23g FeSO 4 x7H 2 O, completely dissolved, so that the molar ratio of iron to arsenic in the solution is 2:1, and 1.0g of seed FeAsO is added. 4 ·2H 2 O, and inoculated with acid-resistant and arsenic-resistant acidophilic Thiobacillus ferrooxidans, and adjusted the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com