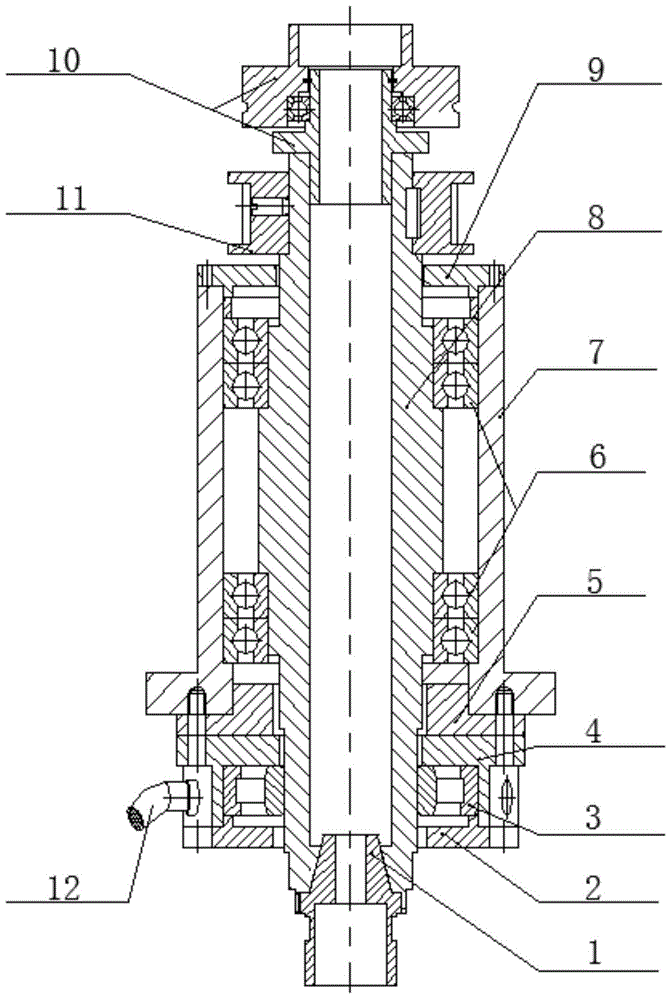

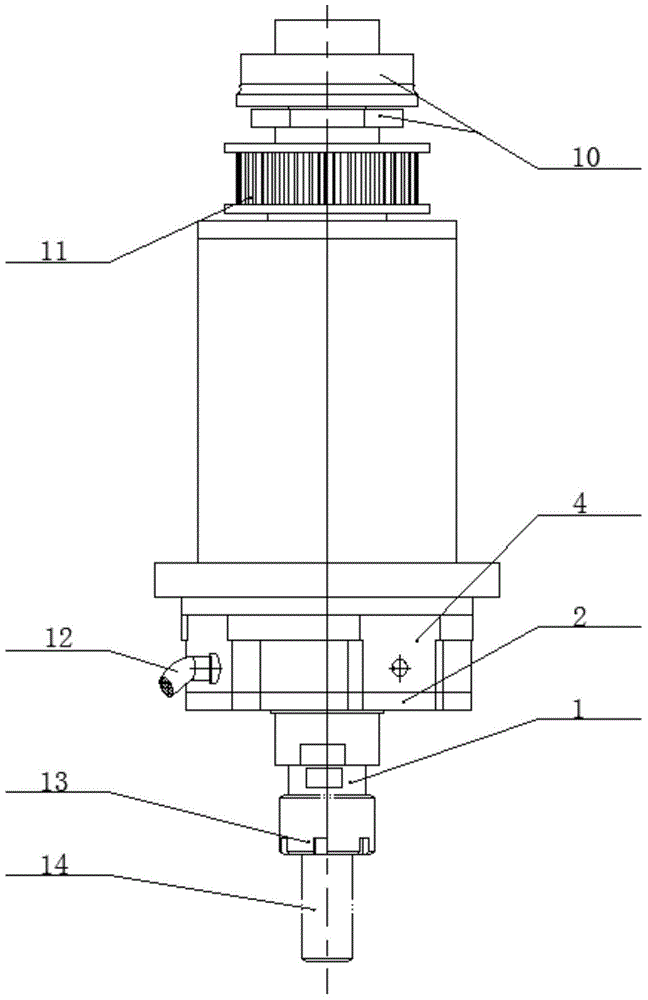

High-speed arc discharge, flushing and rotating main shaft device

A technology of arc discharge and rotating spindle, which is applied in the direction of accessory devices, electrode manufacturing, electric processing equipment, etc. It can solve the problems of limited conductive overcurrent capacity of brushes, current conduction of a large number of contact cores, and high development costs, so as to improve reliability. The simplicity of maintenance guarantee, the reduction of the difficulty of rotating conduction, and the optimization of the effect of the conductive contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Fix the tool electrode 14 with a diameter of 20mm on the custom-made tool handle 1 through the water stop chuck assembly 13, and at the same time fasten the 1-inch water pump water supply pipe to the rotary joint 10 through the pipe interface thread, and adjust the pressure of the water supply overflow valve 1- 2MPa, the fluid inside the mandrel 8 is supplied to the tool electrode 14 through the customized tool handle 1 under the action of the pressure difference, and is sprayed out from the flushing hole on the tool electrode 14 to realize the flushing liquid in the electrode; turn on the discharge power, set the discharge current, the current of the discharge wire 12 passes through the conductive disk 4 and the conductive bearing 3, and then converts the power supply of the static wire into the rotation power supply of the mandrel 8, and is finally conducted to the tool electrode 14 by the customized tool handle 1 and the water stop chuck assembly 13 , The plasma is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com