Collophanite froth flotation collecting agent and preparation method thereof

A foam flotation and collector technology, applied in flotation, solid separation and other directions, can solve the problems of low phosphorus recovery rate, poor selectivity, poor hard water resistance, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

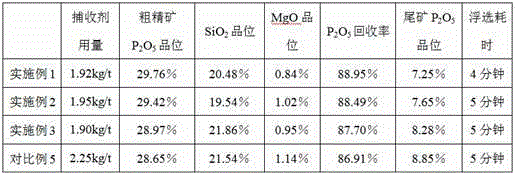

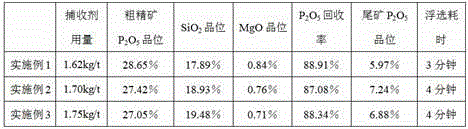

Examples

Embodiment 1

[0019] (1) Prepare materials according to the following parts by mass: 0.75 parts of stearic acid, 0.2 parts of oleic acid, and 0.05 parts of citric acid;

[0020] (2) Mix stearic acid and oleic acid in step (1) evenly, add 0.15 parts by mass of sodium hydroxide solution with a concentration of 30wt% after mixing evenly, and carry out saponification reaction at 80-90°C for 30 minutes to obtain saponified product ;

[0021] (3) Add the citric acid in step (1) to the saponified product obtained in step (2) and mix evenly to obtain a mixture;

[0022] (4) Add 0.05 parts by mass of sodium chloride to the mixture obtained in step (3) for salting out, and then dry to obtain a dry basis;

[0023] (5) Add dimethyl phthalate of 5% dry basis mass to the dry basis substance obtained in step (4), and stir to obtain the basic substance;

[0024] (6) Add 2% diesel oil by mass of the basic substance to the basic substance obtained in step (5), and stir evenly to obtain a collophosite foam ...

Embodiment 2

[0027] (1) Prepare materials according to the following parts by mass: 0.6 parts of stearic acid, 0.3 parts of oleic acid, and 0.1 parts of citric acid;

[0028] (2) Mix stearic acid and oleic acid in step (1) evenly, add 0.25 parts by mass of sodium hydroxide solution with a concentration of 40wt% after mixing evenly, and carry out saponification reaction at 90-100°C for 45 minutes to obtain saponified product ;

[0029] (3) Add the citric acid in step (1) to the saponified product obtained in step (2) and mix evenly to obtain a mixture;

[0030] (4) Add 0.15 parts by mass of sodium chloride to the mixture obtained in step (3) for salting out, and then dry to obtain a dry basis;

[0031] (5) Add sodium dodecylsulfonate of 8% dry basis mass to the dry basis substance obtained in step (4), and stir to obtain the basic substance;

[0032] (6) Diesel oil with a mass of 8% of the basic substance is added to the basic substance obtained in step (5), and after stirring evenly, a c...

Embodiment 3

[0035] (1) Prepare materials according to the following parts by mass: 0.3 parts of stearic acid, 0.5 parts of oleic acid, and 0.2 parts of citric acid;

[0036] (2) Mix stearic acid and oleic acid in step (1) evenly, add 0.10 parts by mass of sodium hydroxide solution with a concentration of 45wt% after mixing evenly, and carry out saponification reaction at 100-120°C for 60 minutes to obtain saponified product ;

[0037] (3) Add the citric acid in step (1) to the saponified product obtained in step (2) and mix evenly to obtain a mixture;

[0038] (4) adding 0.2 parts by mass of sodium chloride to the mixture obtained in step (3) for salting out, and then drying to obtain dry matter;

[0039] (5) Add sodium dodecylbenzenesulfonate with 15% dry basis mass to the dry substance obtained in step (4), and stir to obtain the basic substance;

[0040] (6) Diesel oil with a mass of 1% of the basic substance is added to the basic substance obtained in step (5), and after stirring ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com