Micro-fluidic chip surface hydrophilic modification treatment method and hydrophilic surface gradient manufacture method

A microfluidic chip and processing method technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve problems such as poor modification effect, blurred boundaries, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

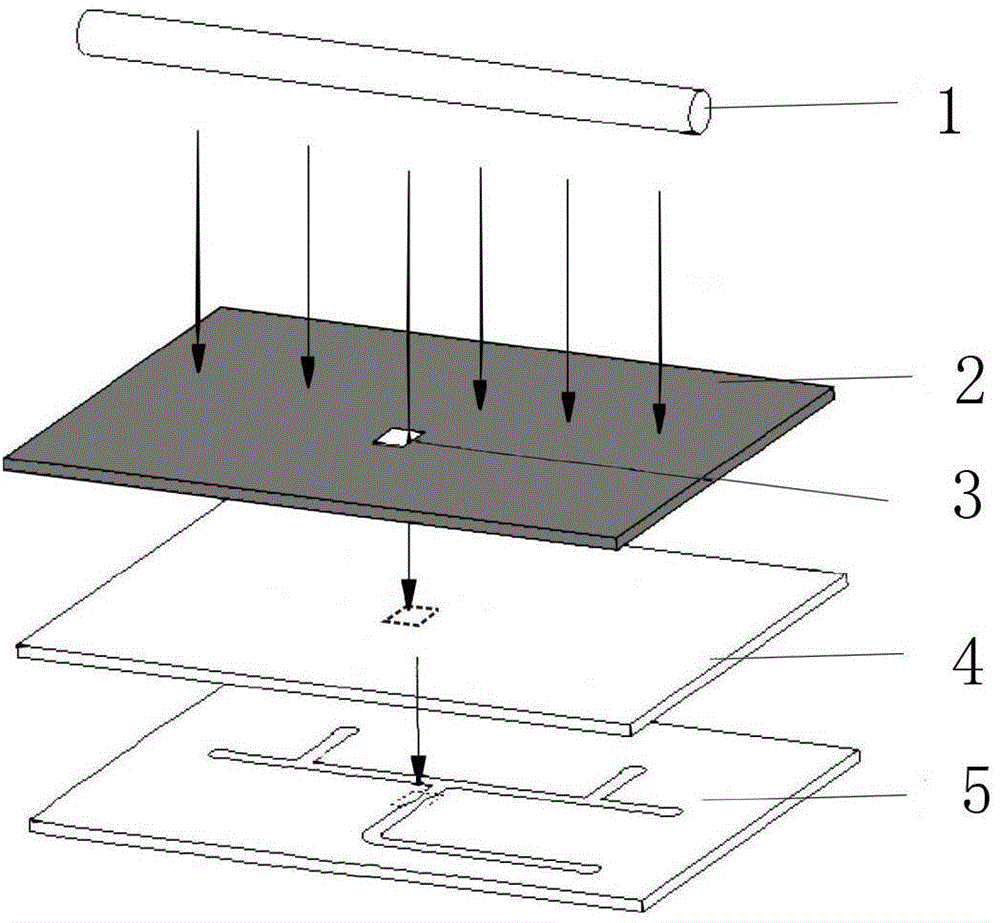

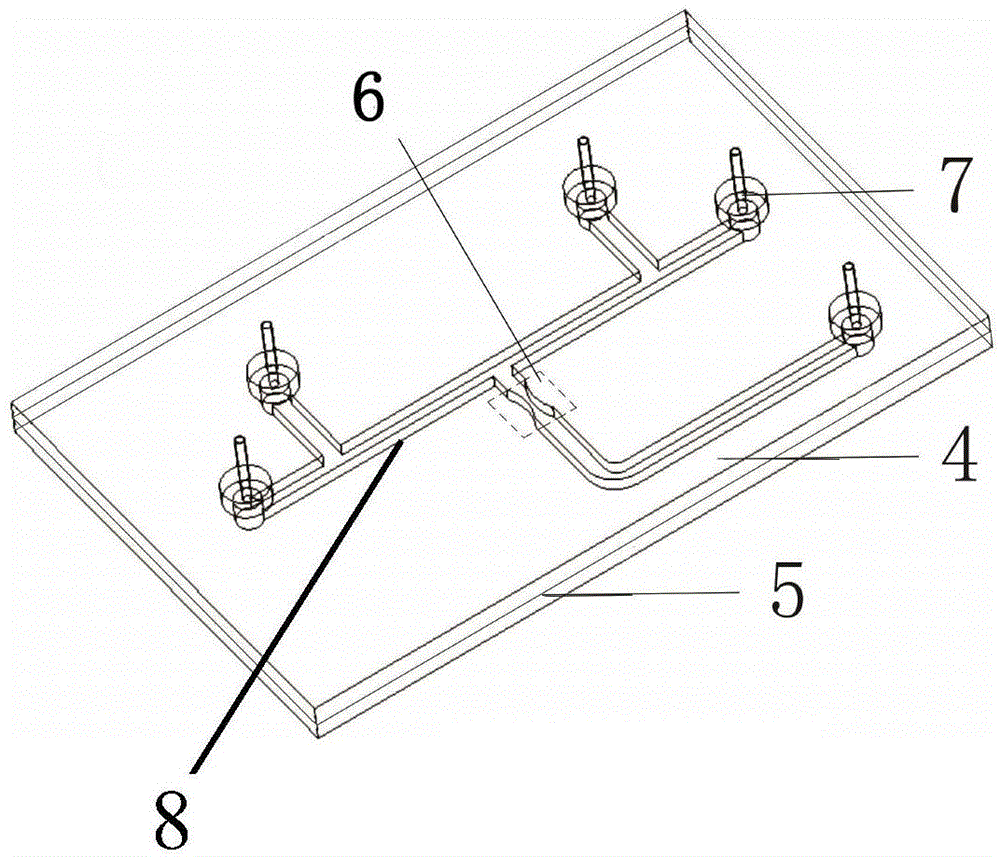

[0040] Such as figure 1 , figure 2 As shown, a treatment method for hydrophilic modification of the surface of a microfluidic chip, the material of the cover plate 4 and the bottom plate 5 of the microfluidic chip in this embodiment is polymethyl methacrylate, including the following steps:

[0041] (1) configuring a hydrophilic solution: using absolute ethanol to configure a benzophenone solution with a mass fraction of 3% as a photoinitiator, and then mixing the benzophenone solution with acrylic acid to obtain a hydrophilic solution;

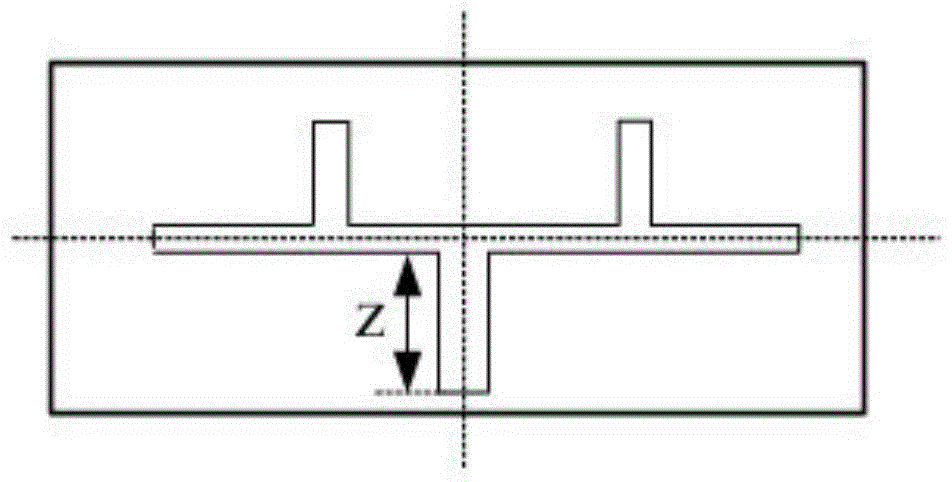

[0042] (2) According to the required hydrophilic treatment area 6 pattern positions of the microfluidic chip pipeline 8, the mask plate 2 is made, and the mask plate light hole 3 on the mask plate 2 is aligned with the hydrophilic treatment area 6, so that Ultraviolet light can be irradiated to the hydrophilic treatment area 6 through the light-transmitting hole, and the mask plate 2 is made of CO 2 Obtained by laser etching, the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com