Ion sensing film and preparation method thereof

An ion-sensing, one-sided technology, applied in the field of medical devices, can solve the problems of poor therapeutic effect, single electrostatic or magnetic therapy, and small application range, and achieve the goal of enhancing immunity, good biocompatibility, and improving cell activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

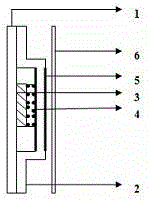

Image

Examples

example 1

[0038] In the first step, the medical grade polylactic acid with a molecular weight of 10W is added to ethyl acetate to dissolve to obtain a mixed solution. In order to ensure that the mixed solution completely dissolves the medical grade polylactic acid without residue, stir at room temperature with a magnetic stirrer at a speed of 100r / min 5 minutes until completely dissolved, then the mixed solution was mixed by ultrasonic vibration, exhausted for 30 minutes, and then the exhausted mixed solution was molded, turned, calendered, and cut to form a polylactic acid film with a film thickness of 0.3mm. Among them, the molded The temperature is 250°C;

[0039] In the second step, spread the polylactic acid film cut into 100mm*100mm on a flat panel, and after cleaning the film with alcohol, put PVDC (vinylidene chloride-acrylate copolymer) with good barrier properties on the polylactic acid film Coating on one side, and then drying in an oven for 48 hours to form a composite film;...

example 2

[0046] In the first step, the medical grade polylactic acid with a molecular weight of 20W is added to ethyl acetate to dissolve to obtain a mixed solution. In order to ensure that the mixed solution completely dissolves the medical grade polylactic acid without residue, stir with a magnetic stirrer at a speed of 100r / min at room temperature 5 minutes until completely dissolved, then the mixed solution was mixed by ultrasonic vibration, exhausted for 30 minutes, and then the exhausted mixed solution was molded, turned, calendered, and cut to form a polylactic acid film with a film thickness of 0.5mm. Among them, the molded The temperature is 280°C;

[0047] In the second step, spread the polylactic acid film cut into 100mm*100mm on a flat panel, clean the film with alcohol, and then coat one side of the polylactic acid film with PTFE (polytetrafluoroethylene) with good barrier properties. Cover, and then dry in an oven for 48 hours to make a composite film;

[0048] The third...

example 3

[0054] In the first step, add medical grade polylactic acid with a molecular weight of 30W to ethyl acetate to dissolve to obtain a mixed solution. In order to ensure that the mixed solution completely dissolves the medical grade polylactic acid without residue, stir with a magnetic stirrer at a speed of 100r / min at room temperature 5min until completely dissolved, then the mixed solution was mixed by ultrasonic vibration, exhausted for 30min, and then the exhausted mixed solution was molded, turned, calendered, and cut to form a polylactic acid film with a film thickness of 0.7mm. Among them, the molded The temperature is 300°C;

[0055] In the second step, spread the polylactic acid film cut into 100mm*100mm on a flat panel, and after cleaning the film with alcohol, place PVDF (polydenetetrafluoroethylene) with good barrier properties on one side of the polylactic acid film. Coating, and then drying in an oven for 48 hours to make a composite film;

[0056] The third step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com