Nickel-cobalt lithium aluminate composite positive electrode material and preparation method thereof

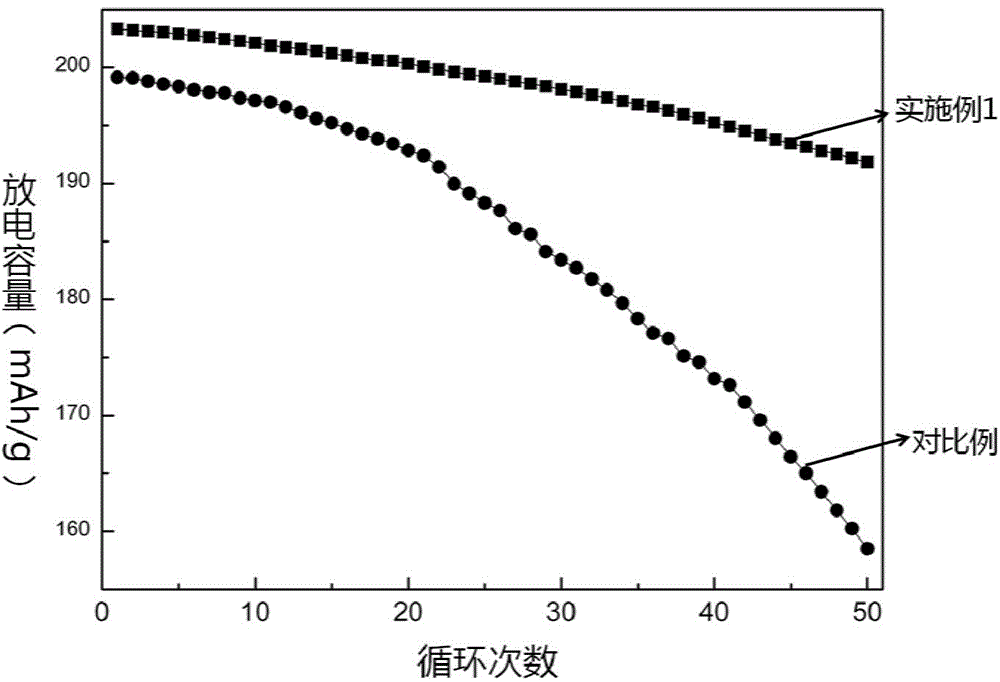

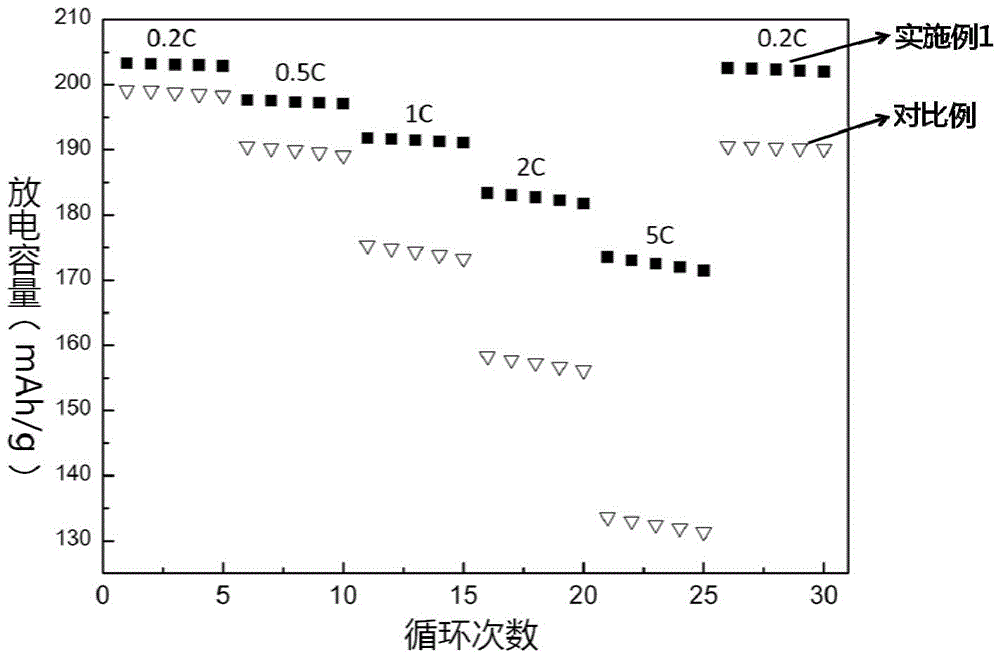

A composite cathode material, lithium nickel cobalt aluminate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor cycle performance and rate performance, and achieve improved rate performance, improved cycle performance, inhibited The effect of interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

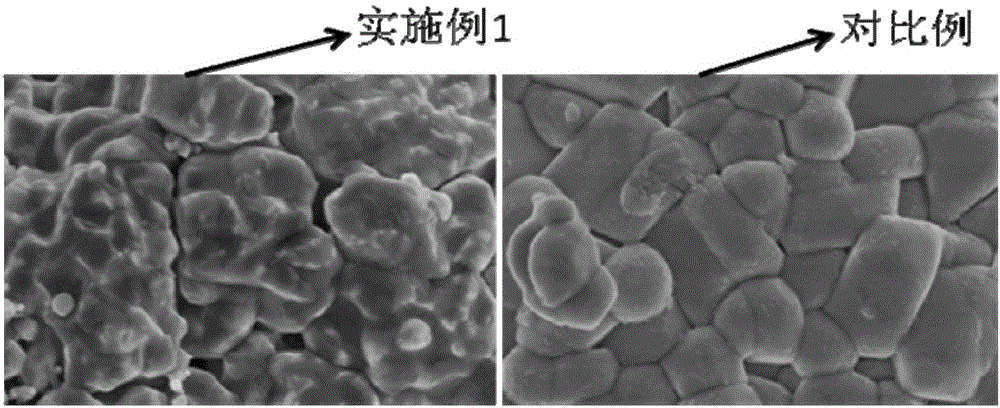

Embodiment 1

[0054] (1) Weigh 7.5002g Al(NO 3 ) 3 9H 2 Dissolve O in 500mL of ionized water, stir until completely dissolved, and set aside;

[0055] (2) Weigh 1.2g NaOH and dissolve it in 500mL ionized water to prepare a lye with a concentration of 0.06mol / L, and set aside;

[0056] (3) Weigh 250g LiNi 0.815 co 0.15 al 0.035 o 2 Add it to the above aluminum nitrate solution, stir for 10 minutes, adjust the pH value to 8.5 with sodium hydroxide solution, continue to stir for 30 minutes, filter with suction, and wash with deionized water for 3 times;

[0057] (4) Then the obtained suction filtrate was kept at 300° C. for 4 hours in an air atmosphere, cooled to room temperature naturally, and sieved with a 200-mesh metal screen to obtain a sample compounded with Al2O3;

[0058] (5) Weigh 2.5g of acetylene black and disperse it in 500mL of pure water, stir and mix for 30min, add the sample compounded with aluminum oxide obtained above and continue to stir for 30min, then use the thicke...

Embodiment 2

[0062] (1) Weigh 15.004g Al(NO 3 ) 3 9H 2 Dissolve O in 500mL of ionized water, stir until completely dissolved, and set aside;

[0063] (2) Weigh 1.2g NaOH and dissolve it in 500mL ionized water to prepare a lye with a concentration of 0.06mol / L, and set aside;

[0064] (3) Weigh 250g Li 0.96 Ni 0.8 co 0.15 al 0.05 o 2 Add it to the above aluminum nitrate solution, stir for 30 minutes, adjust the pH value to 8 with sodium hydroxide solution, continue to stir for 10 minutes, filter with suction, and wash with deionized water for 5 times;

[0065] (4) Then the obtained suction filtrate was kept at 600° C. for 4 hours in an air atmosphere, cooled naturally to room temperature, and passed through a 200-mesh metal screen to obtain a sample compounded with Al2O3;

[0066] (5) Weigh 2.5g graphene and disperse it in 500mL pure water, stir and mix for 30min, add the sample compounded with aluminum oxide obtained above and continue to stir for 30min, then use thickener carboxym...

Embodiment 3

[0070] (1) Weigh 6.662g Al 2 (SO4) 3 18H 2 O was dissolved in 500mL deionized water, stirred until completely dissolved, and set aside;

[0071] (2) Weigh 1.2g NaOH and dissolve it in 500mL deionized water to prepare a lye solution with a concentration of 0.06mol / L for use;

[0072] (3) Weigh 250g LiNi 0.9 co 0.05 al 0.05 o 2 Add it to the above aluminum sulfate solution, stir for 30 minutes, adjust the pH value to 8 with sodium hydroxide solution, continue to stir for 30 minutes, filter with suction, and wash with deionized water for 3 times;

[0073] (4) Then the obtained suction filtrate was kept at 400° C. for 9 hours in an air atmosphere, naturally cooled to room temperature, and passed through a 200-mesh metal screen to obtain a sample compounded with Al2O3;

[0074] (5) Weigh 2.5g of carbon nanotubes and disperse them in 500mL of pure water, stir and mix for 30 minutes, add the sample compounded with aluminum oxide obtained above and continue to stir for 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com