Control method of minimum-flow recirculation valve of water supply pump of power station boiler

A minimum flow, recirculation valve technology, applied in the control of water supply, preheating, steam generation, etc., can solve the problems of frequent and unstable adjustment of the recirculation valve, internal leakage of the valve core, and premature opening, etc., to improve the control stability. , to avoid spool scouring, the effect of smooth control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and do not limit the protection scope of the present invention.

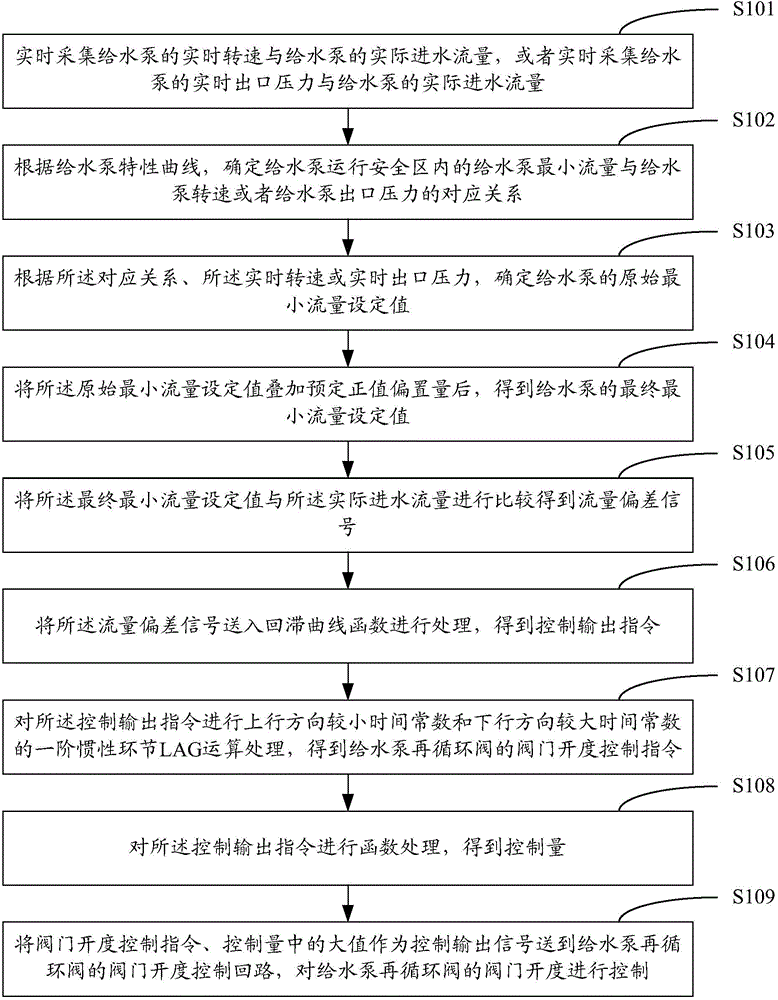

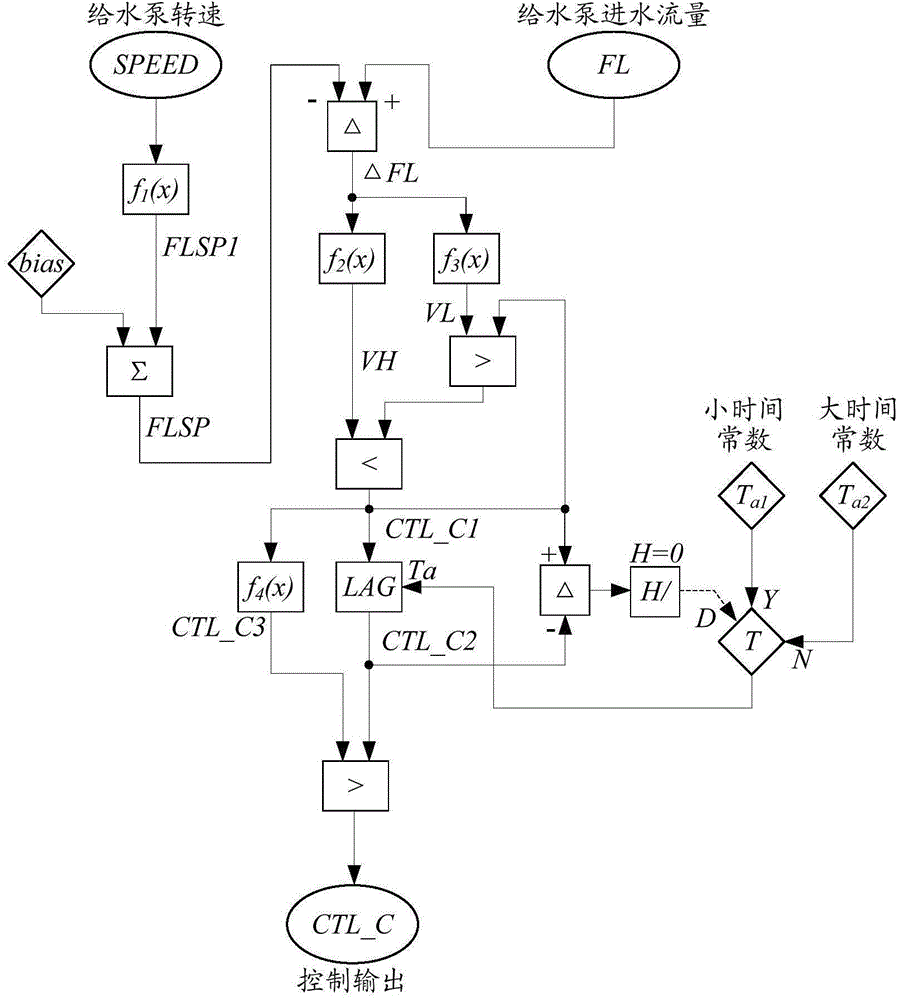

[0027] figure 1 A schematic flowchart of a method for controlling a minimum flow rate recirculation valve of a utility boiler feed water pump according to an embodiment of the present invention is shown in . Such as figure 1 As shown, the method in this embodiment includes steps:

[0028] Step S101: collecting the real-time rotational speed of the feedwater pump and the actual water inlet flow of the feedwater pump in real time, or collecting the real-time outlet pressure of the feedwater pump and the actual water inlet flow of the feedwater pump in real time;

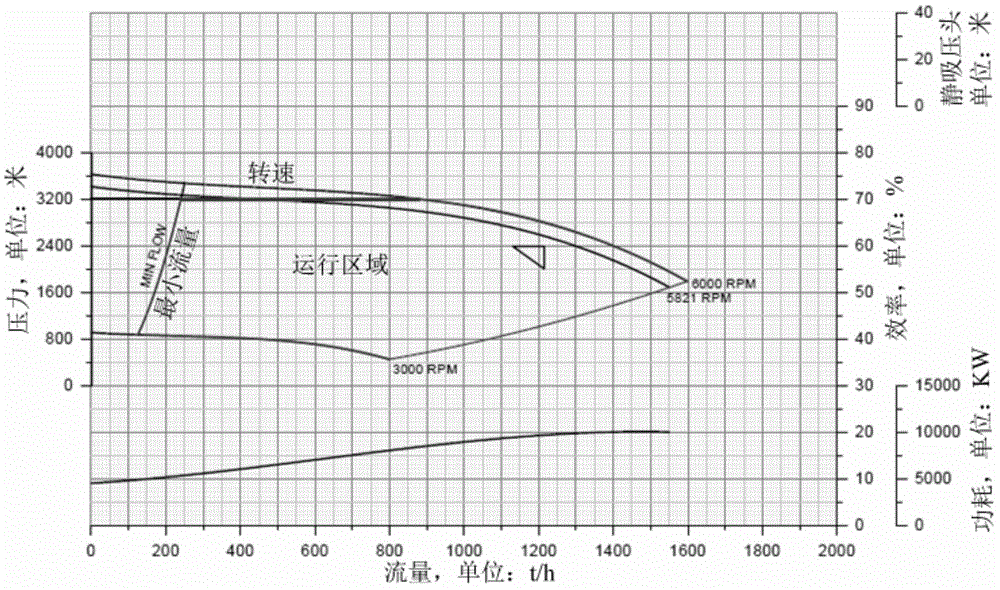

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com