Rapid composite roof roadway support method for high-stress water guiding karst cave group

A composite roof, high stress technology, applied in mine roof supports, tunnels, earthwork drilling and other directions, can solve problems such as the failure of the support capacity to achieve the expected support effect, the normal construction of the roadway, and the excessive pressure of the surrounding rock. The installation process is convenient and quick, the maintenance works are reduced, and the supporting cost is saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

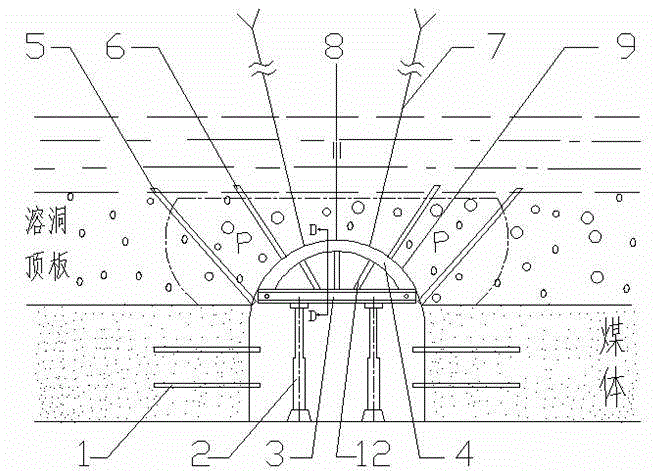

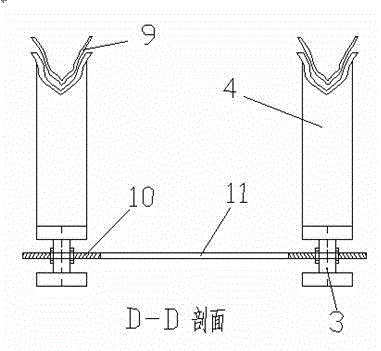

[0027] Implement a kind of fast supporting method for composite roof roadway of high-stress water-conducting karst cave group, and its described method is to carry out as follows:

[0028] Step 1. After the excavation of the roadway is formed, the side anchor rod 1 is driven into the two sides of the roadway for support, and the coal side is controlled first, and then the self-drilling arch foot grouting anchor is implanted in the roadway arch foot and vault 5 and self-drilling vault grouting bolts 6, with a row spacing of 1.0-1.5m.

[0029] This support method is due to the excavation of the roadway. The two arches and the top of the arch will produce stress concentration phenomena. The maximum stress at the two arches can reach 2 to 5 times the stress of the original rock. On the one hand, the pole can improve the bearing capacity of the rock mass at the vault and arch foot of the roadway, effectively control the slipping, instability and deformation of the rock mass at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com