Waste water pump repairing and coating method

A technology for waste and water pumps, which is applied to coatings, devices for coating liquid on surfaces, and surface pretreatment, etc. It can solve problems such as reduced water extraction efficiency, low-efficiency operation of water pumps, and damage to pump bodies, and achieves improved gas resistance. Erosion and wear ability, smooth water flow through the flow channel, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

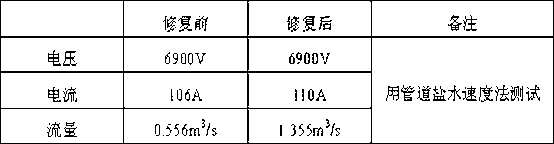

Examples

Embodiment 1

[0025] Example 1 The method for repairing and coating the waste water pump includes the following steps:

[0026] ⑴Preparation work: first set up the heat preservation shed, then use the air compressor to drive the sandblasting gun to derust the painted surface of the waste pump body until the fresh metal surface is completely exposed, and finally, make the waste pump body and the heat preservation shed reach 20~30°C .

[0027] ⑵Repair of the diaphragm of the waste pump body: Use an acetylene torch to burn and remove the old coating on the damaged part of the diaphragm, remove the edge of the damaged diaphragm and make it tidy; cut the steel plate with the same size and shape as the damaged diaphragm, and weld it According to the characteristic curve and operating conditions of the pump, the length of the tongue is shortened by 4~30mm, and the end of the tongue is close to the axis and impeller by 3~18mm; preheat the welding part to make the temperature 280 ~320℃, interm...

Embodiment 2

[0032] Example 2 The method for repairing and coating the waste water pump includes the following steps:

[0033] ⑴Preparation work: first set up a heat preservation shed, then use solvent acetone to clean the oil stains on the waste pump body, and then use an air compressor to drive a sandblasting gun to derust the painted surface of the waste pump body until the fresh metal surface is completely exposed. Finally, use The waste pump body and the heat preservation shed reach 20~30°C.

[0034] ⑵Repair of the diaphragm of the waste pump body: Use an acetylene torch to burn and remove the old coating on the damaged part of the diaphragm, remove the edge of the damaged diaphragm and make it tidy; cut the steel plate with the same size and shape as the damaged diaphragm, and weld it According to the characteristic curve and operating conditions of the pump, the length of the tongue is shortened by 4~30mm, and the end of the tongue is close to the axis and impeller by 3~18mm; p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com