Hard top plate waterflooding pressure relief treatment method

A technology of water injection pressure relief and hard roof, applied in earth-moving drilling, discharging machinery, ground mining, etc., can solve the problems of heavy workload, impact danger, gap, etc., and achieve the effect of reducing workload and ensuring safe mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

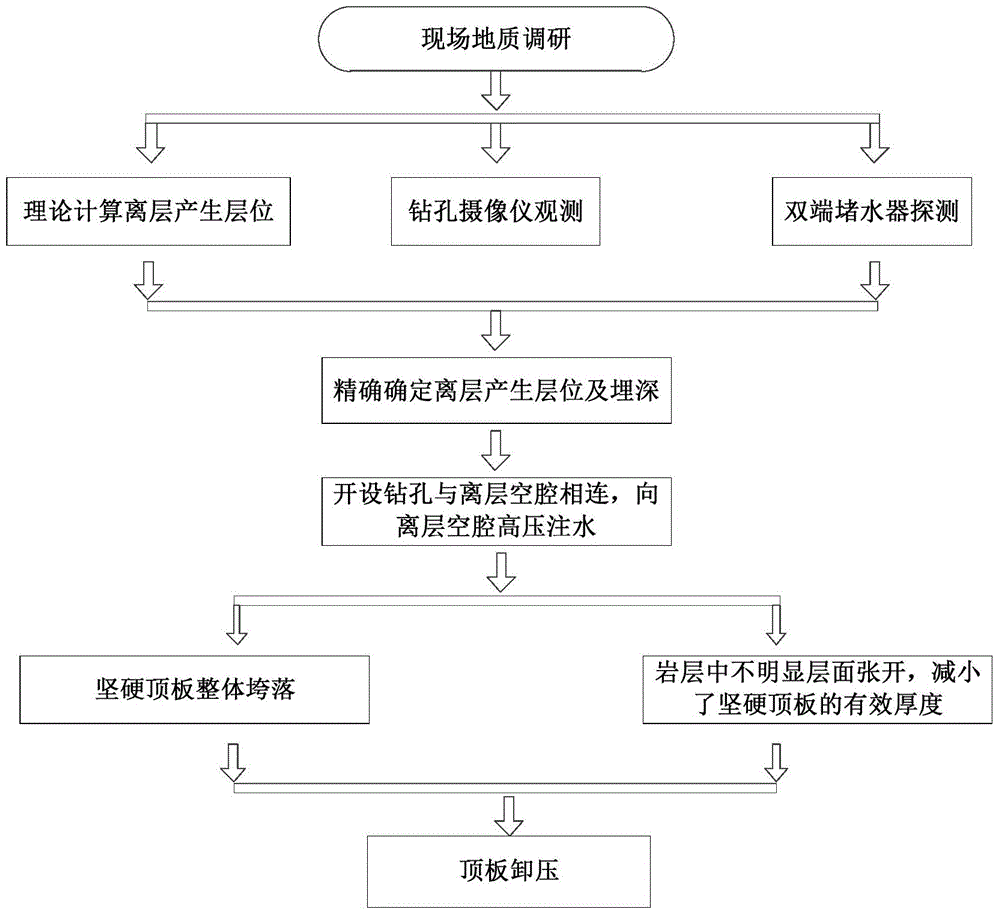

[0024] combine figure 1 As shown, a method for water injection and pressure relief of a hard roof comprises the following steps:

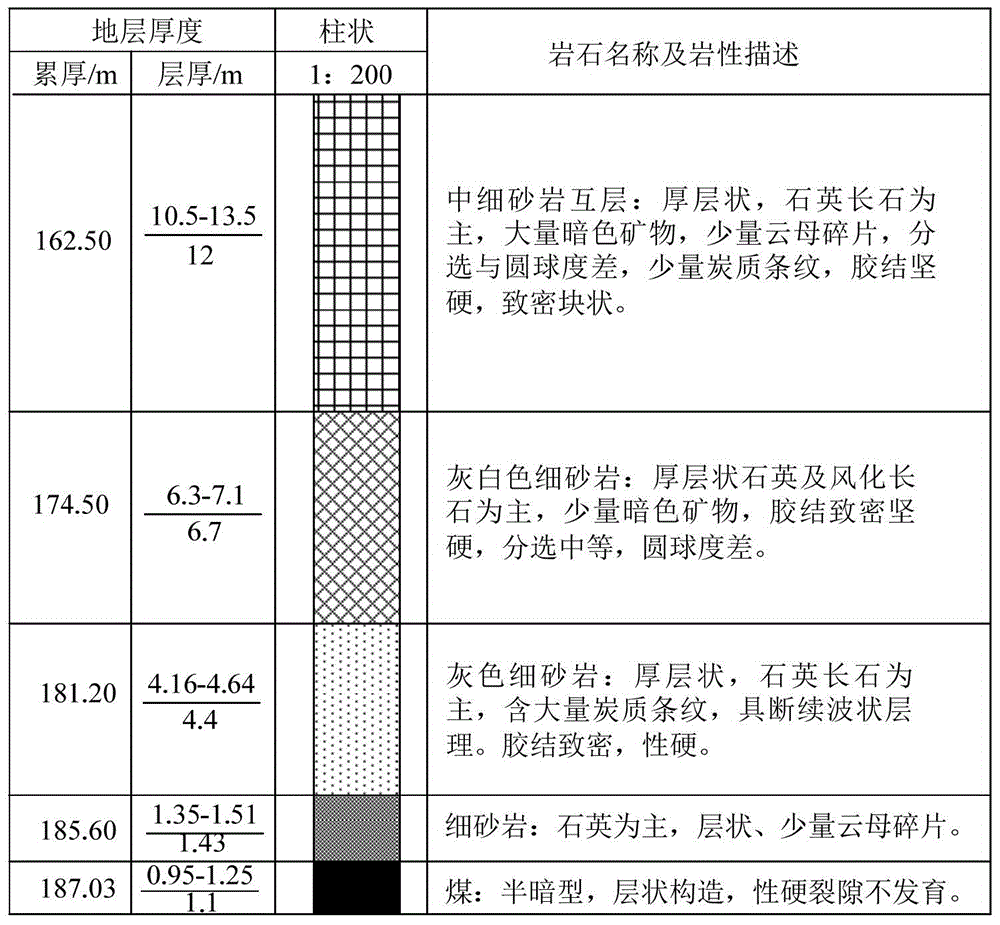

[0025] The first step: select the 7605 working face of a certain mine as the research object, the comprehensive histogram of the working face is as follows figure 2 As shown, based on the experimental data of rock mechanics, the horizon generated by the abscission layer is calculated, and the specific parameters are shown in Table 1.

[0026] Table 1 Lithology parameters

[0027]

[0028] Among them, the calculation of the horizon of the immediate top abscisive layer is calculated according to the formula (1):

[0029] (w i+1 ) 1 =E 1 h 1 3 ( 1 h 1 +γ i+1 h i+1 ) / (E 1 h 1 3 +E i+1 h i+1 3 ) (1)

[0030] Among them, the values of i are 0, 1, 2 respectively.

[0031] It is determined by calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com