Mechanical hand

A manipulator and finger technology, applied in the field of manipulators, can solve the problems of high labor costs, less agricultural labor, and labor difficulties, and achieve the effects of avoiding mechanical damage, reducing mechanical damage, and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

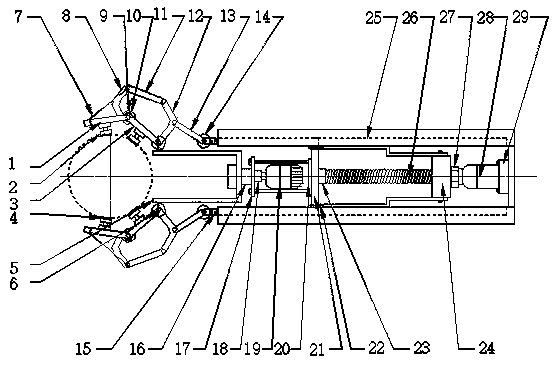

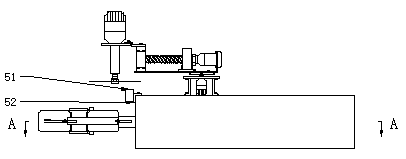

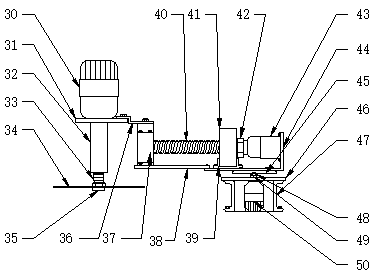

[0026] Such as figure 1 and figure 2 Shown, a kind of manipulator includes: finger linkage mechanism, finger linkage driving part, telescoping part, cutting part and vision system, described finger linkage mechanism is connected with finger linkage driving part, and described finger linkage drives The part is connected with the telescopic part, the cutting part is connected with the fixed slide rail of the telescopic part, and the vision system is connected with the telescopic part.

[0027] according to figure 1, the finger linkage mechanism includes: far knuckle 1, flat plate pressure sensor 2, proximal knuckle 3, silica gel pad 4, support plate 5, connecting rod fixture 6, tension spring 7, remote lever 8, torsion spring 9, Torsion spring fixing part 10, intermediate connecting rod 11, driving rocker 12, driving connecting rod 13, connecting rod fixing part 14 and S-type pressure sensor 15; The two ends of described S-type pressure sensor 15 are respectively connected wi...

Embodiment 2

[0034] The finger link mechanism that the present invention adopts uses extension spring as 7 as a limiting mechanism, so that it has a grasping function; the finger link mechanism adopts a series link mechanism, and the extension spring 7 and the finger link With the cooperation of the mechanism, the target object is grasped, and the finger linkage mechanism can adapt to the shapes of various objects; and considering the vulnerability of fruits, the proximal knuckle 3 and the far knuckle of the finger linkage The middle position of 1 is installed flat plate pressure sensor 2 respectively, is used for sensing the contact force of fruit, avoids the fruit damage that causes because of excessive contact force; The friction force between the fruit and the finger surface has a certain buffering effect on the force applied to clamping the fruit, further reducing the mechanical damage of the force-type clamping to the fruit; A potentiometer is set at the hinge of the S-type pressure ...

Embodiment 3

[0036] The working mode that can be realized by the present invention is to collect the maturity degree, position size, position and stem position information of the target through the industrial camera in the vision system, and then feed back the collected information to the controller, and the controller will process and analyze the collected information And to locate the mature fruit and its stalk, the controller drives each motor to work independently through the motor driver: through the telescopic motor to control the finger linkage mechanism to realize the clamping of the fruit; through the arm telescopic lead screw motor, lifting motor and rotating motor drive, The positioning of the fruit clamping part is realized; the cutting of the stem is realized by controlling the rotation of the circular blade by the shearing motor; the positioning of the cutting part of the fruit stem is realized by driving the shearing telescopic motor and the shearing rotation motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com