Pretreatment method for improving anaerobic biogas-production by penicillin slag

A penicillin slag and biogas production technology, which is applied in the direction of waste fuel, fermentation, etc., can solve the problems of reducing biogas production and anaerobic digestion inhibition, and achieve the effects of reducing residual potency, fully degrading, and increasing nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

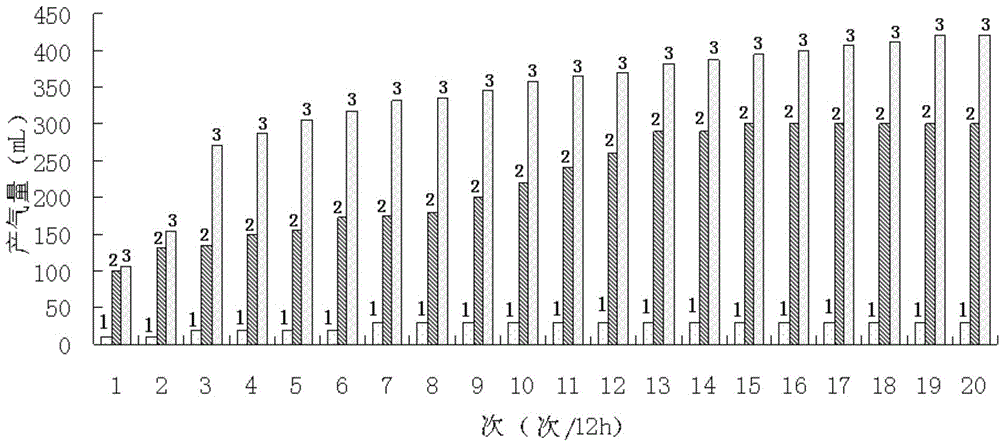

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: a kind of pretreatment method that improves the anaerobic biogas production capacity of penicillin slag described in this embodiment is specifically carried out according to the following steps:

[0018] 1. Take the dehydrated penicillin residue from a pharmaceutical factory that produces antibiotics, then add distilled water and stir evenly to obtain fermentation raw materials, put the fermentation raw materials in a microwave oven, digest them at a temperature of 100°C to 105°C for 55s to 65s, and cool to Room temperature, obtain the penicillin slag after digestion;

[0019] The volume ratio of the quality of penicillin scum after dehydration in the pharmaceutical factory producing antibiotics to distilled water is 1g:(0.2~0.5)mL;

[0020] The water content in the dehydrated penicillin slag of the pharmaceutical factory producing antibiotics is 72.0% to 78.0%, the solid content is 22.0% to 28.0%, and the mass percentage of C in the solid is 45...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that: the penicillin slag after dehydration in the pharmaceutical factory producing antibiotics described in step 1 has a water content of 75.0% and a solid content of 25.0%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass percentage of C in the solid described in step 1 is 47.0%, the mass percentage of N is 10.5%, H The mass percentage content is 7.1%, and the penicillin residue is 2.1mg / g. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com