Biological enzyme-chemical compound catalyst and preparation method and application thereof

A composite catalyst and biological enzyme technology, which can be applied in the fields of biochemical equipment and methods, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that biological enzymes cannot be recycled, increase production costs, etc., and achieve good industrial application prospects. , mild reaction, no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

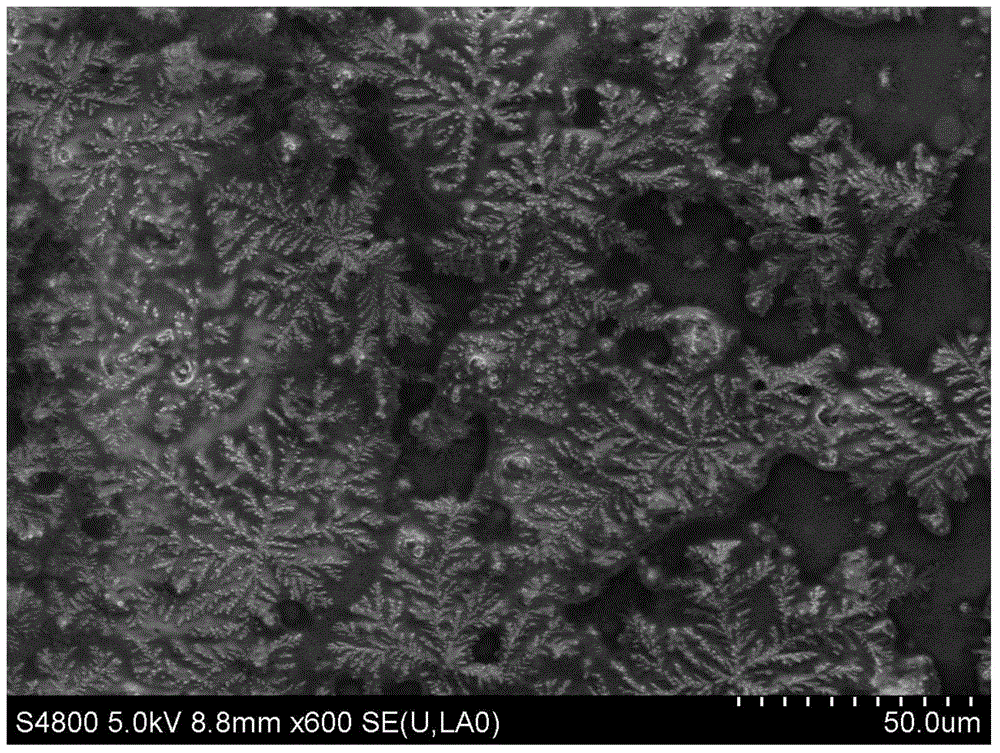

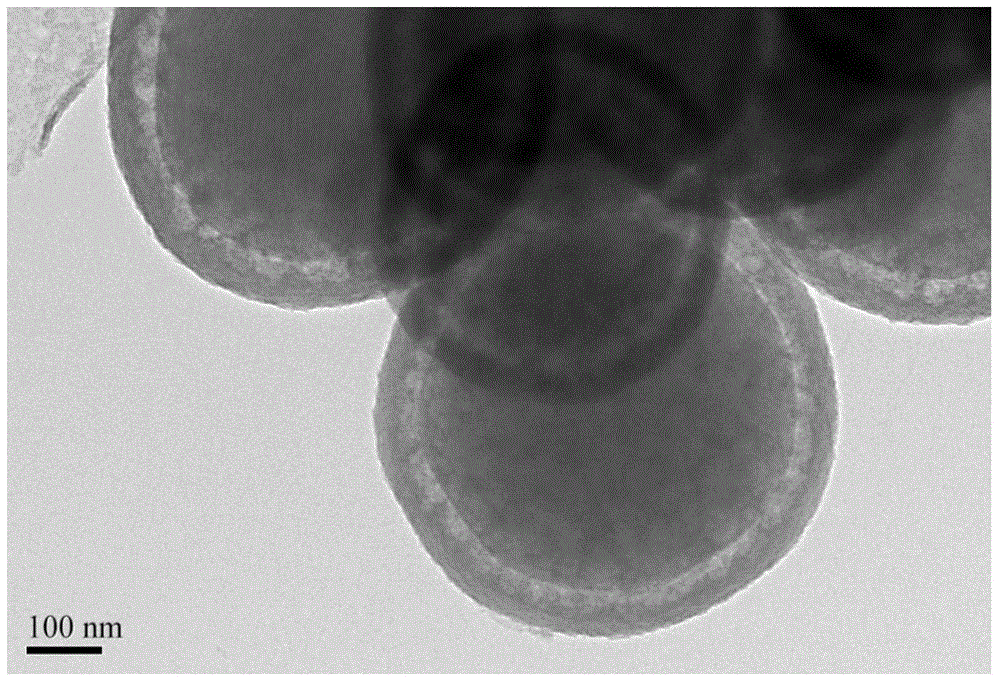

[0030] (1), preparation of chemical catalyst

[0031] Add 0.25g of mesoporous carbon spheres to 1.1mL of 0.06mol / L NH 4 RuCl 6 In aqueous solution, ultrasonic for 15 minutes, stand still for 12 hours, and dry at 100°C for 30 minutes. 0°C and under vigorous stirring, add 2.5 mL of 0.5 mol / L KBH dropwise to the above solution 4 Aqueous solution, stirring was continued for 30 minutes after the dropwise addition was completed. Centrifuge to obtain a black solid, which is repeatedly washed with deionized water until neutral.

[0032] Add the product obtained in the above steps into a mixed solution of 45mL of ethanol, 83mL of water, 0.17g of cetyltrimethylammonium bromide, 62μL of dodecanol and 1.7mL of 30mg / mL sodium hydroxide, and sonicate for 15 minutes. After stirring for 60 minutes, 2.7 mL of tetraethylorthosilicate and 0.2 mL of N-aminoethyl-γ-aminopropyltrimethoxysilane were slowly added dropwise. After stirring at 60°C for 3 hours, the product was washed by centrifugat...

Embodiment 2

[0040] (1), the preparation of chemical catalyst is the same as embodiment 1.

[0041] (2) A cross-linking reaction

[0042]Add the chemical catalyst with a core-shell structure obtained in step (1) and 50 μL of glutaraldehyde into 25 mL of water, sonicate for 15 minutes, stir for 15 minutes, centrifuge and wash three times, add 25 μL of glucoamylase, 25 mL of water, and stir in an ice-water bath for 4 hours. Centrifuge to obtain a black solid, which is repeatedly washed with deionized water until neutral.

[0043] (3) The secondary crosslinking reaction is the same as in Example 1, and the sample is marked as EI-Ru-B / mCairmSiO 2 -2.

Embodiment 3

[0045] (1), the preparation of chemical catalyst is the same as embodiment 1.

[0046] (2) A cross-linking reaction

[0047] Add the chemical catalyst with a core-shell structure obtained in step (1) and 150 μL of glutaraldehyde into 25 mL of water, sonicate for 15 minutes, stir for 15 minutes, centrifuge and wash three times, add 25 μL of glucoamylase, 25 mL of water, and stir in an ice-water bath for 4 hours. Centrifuge to obtain a black solid, which is repeatedly washed with deionized water until neutral.

[0048] (3) The secondary crosslinking reaction is the same as in Example 1, and the sample is marked as EI-Ru-B / mCairmSiO 2 -3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com