Method for preparing nanoparticle dual-mode fluorescent probe by virtue of co-assembly technology

A technology of nanoparticles and fluorescent probes, applied in the field of preparation of nano-fluorescent probes, which can solve the problems of low biocompatibility, poor water solubility, and large size of composite nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

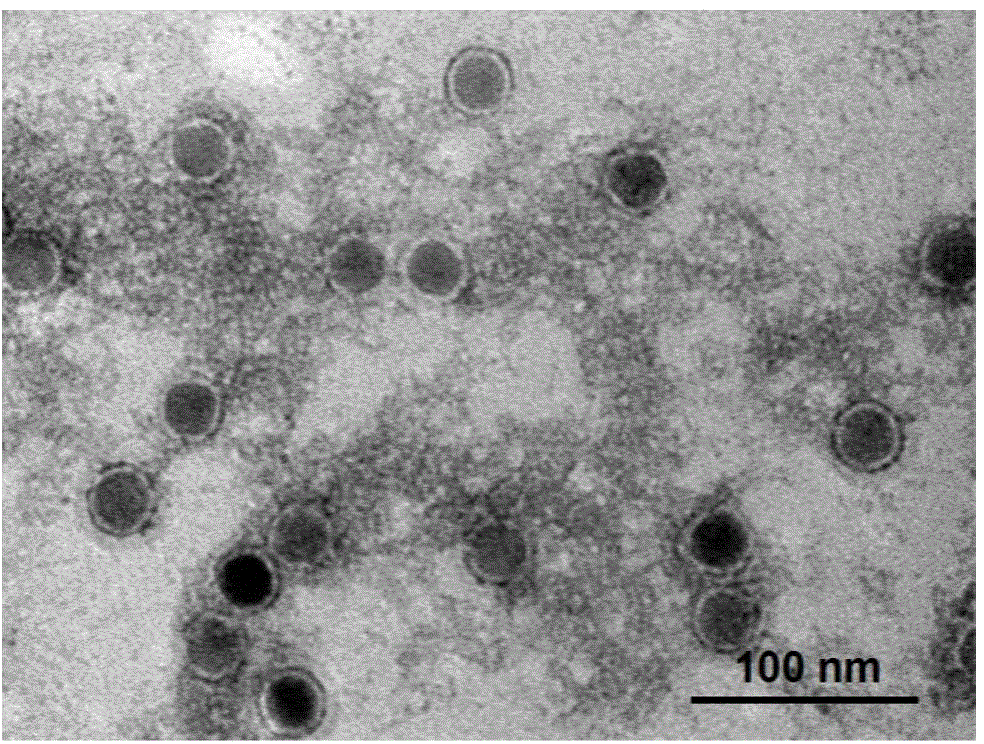

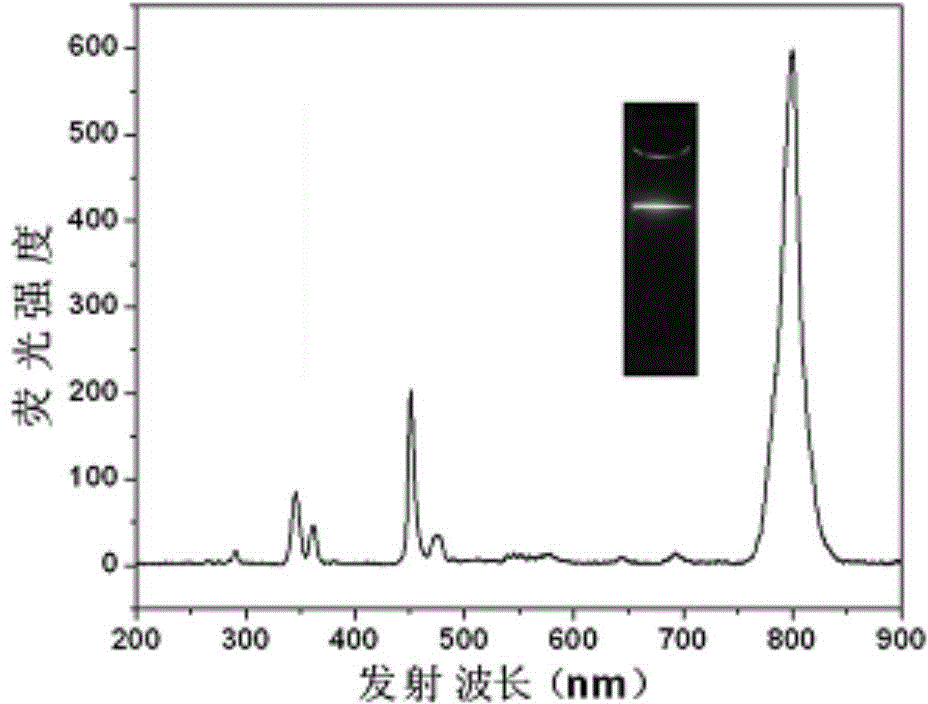

[0024] 1) The oleic acid (OA, Z-9-octadecenoic acid) ligand is coated with blue light (for the up-converted luminous color, it is only related to the type of rare earth metal doped, and has nothing to do with the size of the nanoparticles, etc. ) upconverting nanoparticles NaYF 4 : Yb, Tm (the molar ratio Y / Yb / Tm during preparation is 80 / 19 / 1; Wang.F., Liu.X.G.Chem.Soc.Rev., 2009,38,976-999) adding organic solvent chloroform Mix and centrifuge with anti-precipitant acetone (the volume ratio of anti-precipitant and organic solvent is 3-1:1), remove excess ligand, and redisperse the precipitate in chloroform at a concentration of 3 mg / mL;

[0025] 2) The orange-emitting (3.3nm) down-conversion nanoparticles CdTe coated with mercaptopropionic acid (MPA) (Zhang.H., Wang.L.P., Xiong.H.M., Hu.L.H., Yang.B.Adv.Mater .2003, 15, 1712-1715) after centrifugation (using a centrifuge at 9000-12000r / min, 10-20min), the precipitate was dispersed in water again.

[0026] 3) At room temperat...

Embodiment 2

[0028] 1) The oleic acid (OA, Z-9-octadecenoic acid) ligand is coated with blue light (for the up-converted luminous color, it is only related to the type of rare earth metal doped, and has nothing to do with the size of the nanoparticles, etc. ) upconverting nanoparticles NaYF 4 : Yb, Tm (the molar ratio Y / Yb / Tm during preparation is 80 / 19 / 1; Wang.F., Liu.X.G.Chem.Soc.Rev., 2009,38,976-999) adding organic solvent chloroform Mix and centrifuge with anti-precipitant acetone (the volume ratio of anti-precipitant and organic solvent is 3-1:1), remove excess ligand, and redisperse the precipitate in chloroform at a concentration of 3 mg / mL;

[0029] 2) Green-emitting (2.2nm) down-conversion nanoparticles CdTe coated with mercaptopropionic acid (MPA) (Zhang.H., Wang.L.P., Xiong.H.M., Hu.L.H., Yang.B.Adv.Mater .2003, 15, 1712-1715) after centrifugation (using a centrifuge at 9000-12000r / min, 10-20min), the precipitate was dispersed in water again.

[0030] 3) NaYF stabilized with ...

Embodiment 3

[0032] 1) The oleic acid (OA, Z-9-octadecenoic acid) ligand is coated with blue light (for the up-converted luminous color, it is only related to the type of rare earth metal doped, and has nothing to do with the size of the nanoparticles, etc. ) upconverting nanoparticles NaYF 4 : Yb, Tm (the molar ratio Y / Yb / Tm during preparation is 80 / 19 / 1; Wang.F., Liu.X.G.Chem.Soc.Rev., 2009,38,976-999) adding organic solvent chloroform Mix and centrifuge with anti-precipitant acetone (the volume ratio of anti-precipitant and organic solvent is 3-1:1), remove excess ligand, and redisperse the precipitate in chloroform at a concentration of 3 mg / mL;

[0033] 2) The down-conversion nanoparticles CdTe coated with mercaptopropionic acid (MPA) (Zhang.H., Wang.L.P., Xiong.H.M., Hu.L.H., Yang.B.Adv.Mater .2003, 15, 1712-1715) after centrifugation (using a centrifuge at 9000-12000r / min, 10-20min), the precipitate was dispersed in water again.

[0034] 3) NaYF stabilized with 3 mg / mL blue-emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com