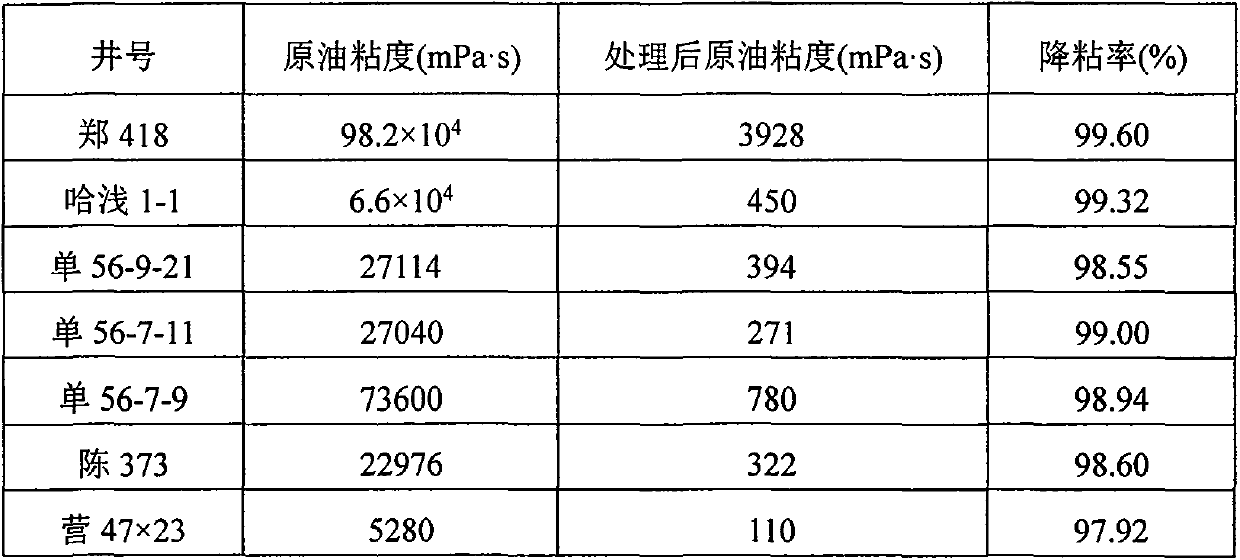

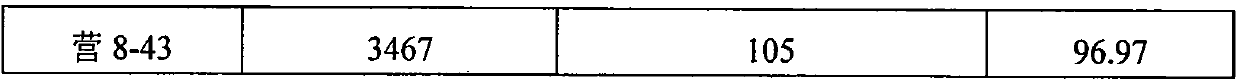

A method for preparing heavy oil viscosity reducer by using gutter oil as raw material

The technology of a viscosity reducer for heavy oil and waste oil is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve problems such as low cost, and achieve the effects of low cost, improved fluidity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] (1) Add 100g of waste oil and 0.3molN,N-dimethyl-1,3-propanediamine into a reaction vessel with a water separator, add 0.1g of sodium hydroxide, mix them, and put them in an oil bath at 160°C Medium constant temperature reaction, the time is 5h, when no water comes out, cool to room temperature for use;

[0008] (2) Put the above reaction product into a reaction vessel with a stirring device, pass nitrogen gas for 15 minutes, drive out the air in the reactor, raise the temperature to 105°C, and slowly drop 0.15mol ethylene glycol diglycidyl ether into it with a dropping funnel , The reaction time was 4h, and the product was obtained. The molecular weight of the product was determined to be 825 by mass spectrometry.

Embodiment 2

[0010] (1) Add 150g of waste oil and 0.3molN,N-dimethyl-1,3-propanediamine into a reaction vessel with a water separator, add 0.1g of sodium hydroxide, mix them, and put them in an oil bath at 160°C Medium constant temperature reaction, the time is 5h, when no water comes out, cool to room temperature for use;

[0011] (2) Put the above reaction product into a reaction vessel with a stirring device, pass nitrogen gas for 15 minutes, drive out the air in the reactor, raise the temperature to 105°C, and slowly drop 0.15mol ethylene glycol diglycidyl ether into it with a dropping funnel , The reaction time was 4h, and the product was obtained. The molecular weight of the product was determined to be 830 by mass spectrometry.

Embodiment 3

[0013] (1) Add 200g of waste oil and 0.3mol N,N-dimethyl-1,3-propanediamine into a reaction vessel with a water separation device, add 0.1g of sodium hydroxide, mix, and place in 160°C oil React at constant temperature in the bath for 5 hours. When no water comes out, stop heating and cool to room temperature for later use;

[0014] (2) Add the above reaction product into a reaction vessel with a stirring device, pass nitrogen gas for 15 minutes, drive out the air in the reactor, raise the temperature to 105°C, and slowly drop 0.15mol of neopentyl glycol diglycidol into it with a dropping funnel Ether, the reaction time was 4h, and the product was obtained. The molecular weight of the product was determined to be 970 by mass spectrometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com