A method for extracting and refining long-chain dibasic acids

A long-chain dibasic acid and extraction technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve the problem of large amount of alkali, high salt content, increased sewage treatment costs, etc. problem, to achieve the effect of less material, high purity and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

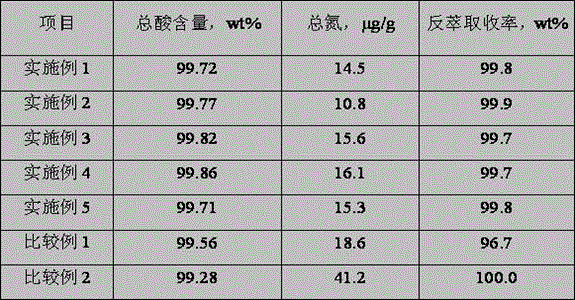

Examples

Embodiment 1

[0038] Take 2000ml and get C by fermenting Candida tropicalis 12 h 22 o 4 Fermented liquid, concentration is the fermented liquid of 160g / L. Heat the terminated fermentation broth at 85°C, let it stand for about 2 hours, then remove the residual liquid wax in the upper layer, then lower the temperature to 70°C, and filter through microfiltration to remove impurities such as bacteria cells to obtain the filtrated liquid. Add H to the filtrate 2 SO 4 Adjust the pH to 2.5 and heat to 90 °C to give C 12 h 22 o 4 The crystallized aqueous solution was cooled to room temperature and filtered to obtain a filter cake.

[0039] Put C 12 h 22 o 4 Filter cake and isobutyl ether (isobutyl ether and C 12 h 22 o 4 The weight ratio is 7:1) mixed, heated to 90°C, stood still for 30min, and separated the lower aqueous phase; then added 300mL deionized water to the solvent phase to wash the organic phase, and separated the aqueous phase again; then added to the organic phase 0.3g o...

Embodiment 2

[0042] Take 2000ml and get C by fermenting Candida tropicalis 12 h 22 o 4 Fermented liquid, concentration is the fermented liquid of 160g / L. The fermented liquid is heated to 85°C, and enters a microfiltration device to remove bacterial cells and liquid wax, etc., to obtain a clarified filtrate containing long-chain dibasic acid salts. Add H to the filtrate 2 SO 4 Adjust the pH to 3.0 and heat to 95 °C to give C 12 h 22 o 4 The crystallized aqueous solution was cooled to room temperature and filtered to obtain a filter cake.

[0043] Will C 12 h 22 o 4 Filter cake and n-butyl ether (n-butyl ether and C 12 h 22 o 4 The weight ratio is 6:1) mixed, heated to 95°C, stood still for 30min, and the lower aqueous phase was separated; 280mL deionized water was added to the solvent phase to wash the organic phase, and the aqueous phase was separated again; 0.2g was added to the organic phase Activated carbon was decolorized by heat preservation for 30 minutes, and then fil...

Embodiment 3

[0046] Take 2000ml and get C by fermenting Candida tropicalis 13 h 24 o 4 Fermented liquid, concentration is the fermented liquid of 154g / L. Heat to 70°C, filter through a ceramic microfiltration membrane, remove bacteria and residual liquid wax to obtain a filtrate. Add H to the filtrate 2 SO 4 Adjust the pH to 2.4 and heat to 95 °C to give C 13 h 24 o 4 The crystallized aqueous solution was cooled to room temperature and filtered to obtain a filter cake.

[0047] Put the obtained C 13 h 24 o 4 Filter cake and n-butyl ether (n-butyl ether and C 13 h 22 o 4 The weight ratio is 4:1), mix, mix and heat to 105°C, stand still for 45min, and remove the lower aqueous phase; then add 310mL deionized water to the solvent phase to wash the organic phase, and then separate the aqueous phase; add 0.15 g activated carbon was decolorized by heat preservation for 30min, and then the activated carbon was removed by filtration.

[0048] Add 130 µg / g of octylphenol polyoxyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com