Calcining method for preparing rutile-type titanium dioxide powder

A technology for preparing gold from rutile titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor quality of rutile titanium dioxide products, low conversion rate of production raw materials, high production energy consumption, etc., and achieve heat preservation time Short, reduce production costs, reduce the effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] A manufacturer produces a kind of rutile titanium dioxide. The raw material is metatitanic acid. The calcining equipment used is a calcining rotary kiln with a designed production capacity of 40,000 tons. The original process parameters obtained by implementing the traditional process are shown in Table 1:

[0075] Table 1 Original process parameters

[0076]

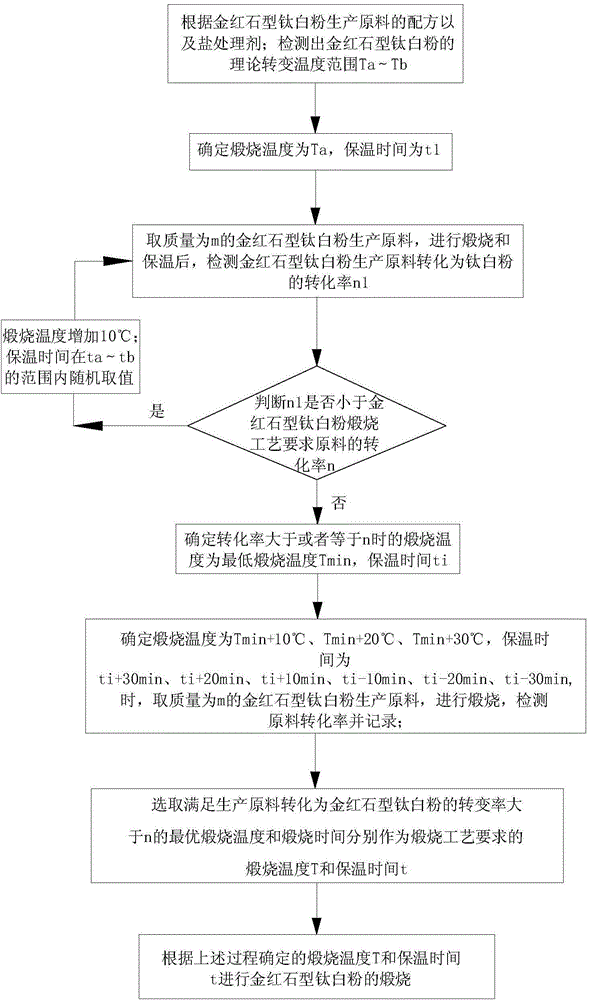

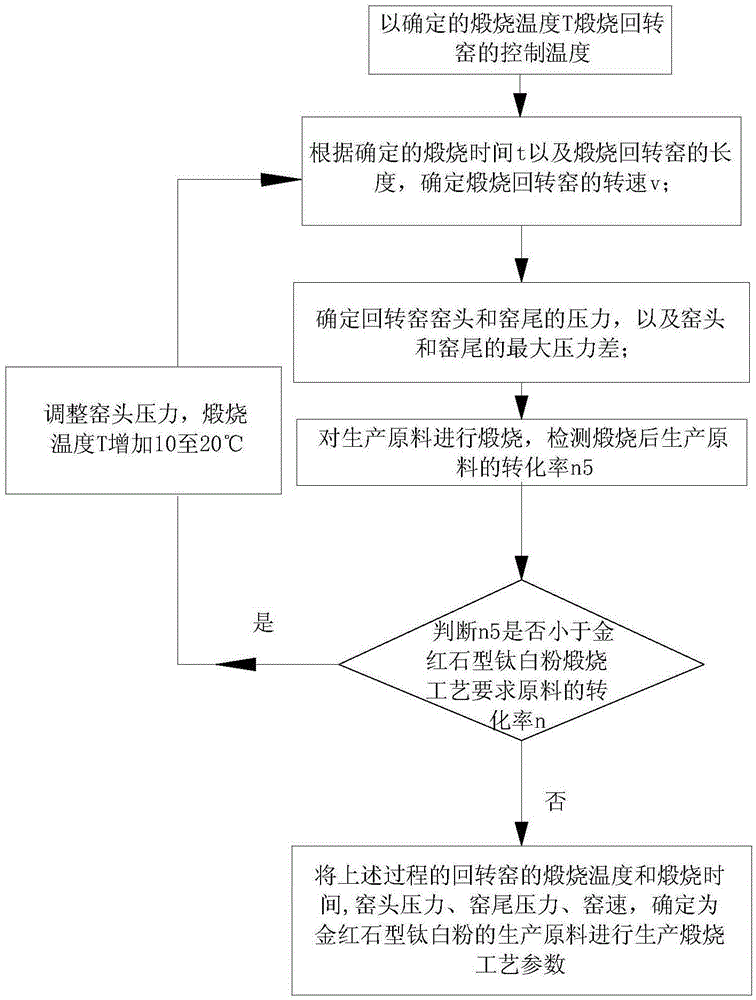

[0077] 1. Determine the optimal calcination temperature T and holding time t

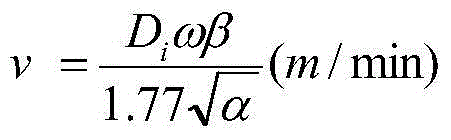

[0078] 1.1 According to the production raw material is metatitanic acid, and the salt treatment agent used; the salt treatment agent is zinc sulfate, zinc chloride, zinc oxide, aluminum oxide, etc. It is detected that the theoretical transformation temperature range of the production raw material into titanium dioxide is 800-1000°C; the holding time of the production raw material in the calcination equipment is 60-90min; the calcination temperature of the production raw material is determined to be 800°C, and the holding time is t1=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com