Making method of anti-static lamination type support pad for protecting LCD panel

An antistatic layer and a technology for its production method are applied in the direction of lamination, lamination devices, chemical instruments and methods, etc., which can solve problems such as product damage and physical property changes, so as to prevent the inflow of foreign matter, reduce the penetration of foreign matter, and reduce product damage or The effect of product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments.

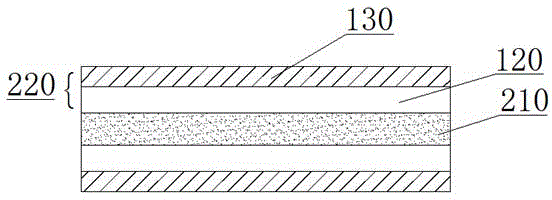

[0022] Refer to figure 1 .

[0023] The manufacturing method of the anti-static laminated support pad for protecting the LCD panel is characterized in that it comprises the following steps:

[0024] (1) In the anti-static film formation stage, method one, spray a conductive material coating liquid on at least one side of the polyolefin film 120, and cross-link it through thermal hardening or light hardening treatment to form an anti-static coating treatment layer 130 of the anti-static film 220; Method two, the anti-static resin added with anti-static conductive material is extruded to form the anti-static film 220, and then heat-bonded or heat-sealed on the layer The finishing stage on the compression support pad.

[0025] (2) In the formation stage of the laminated support pad, the antistatic film (220) obtained in step (1) is laminated to at least one surface of the foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com