Device for grinding lead screw precisely

A lead screw and precision grinding technology, which is applied in the direction of tangent devices, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., can solve the problems of decreased grinding accuracy, affecting grinding effect, and high manufacturing cost, and achieve reduced surface roughness, Improved fatigue strength and service life, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

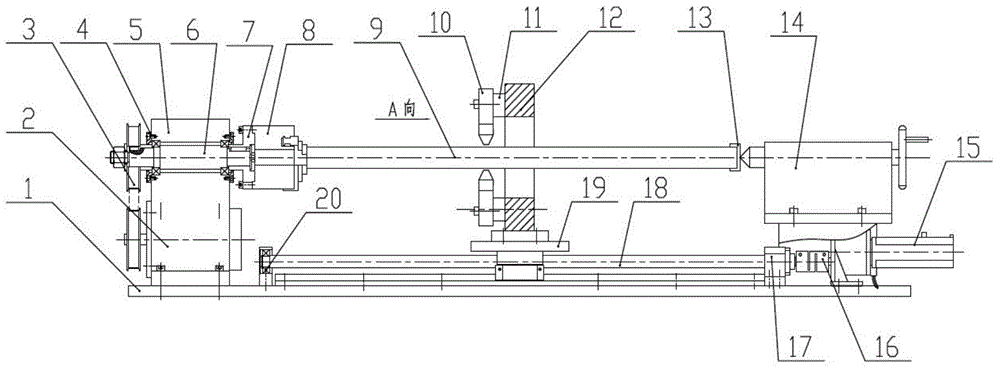

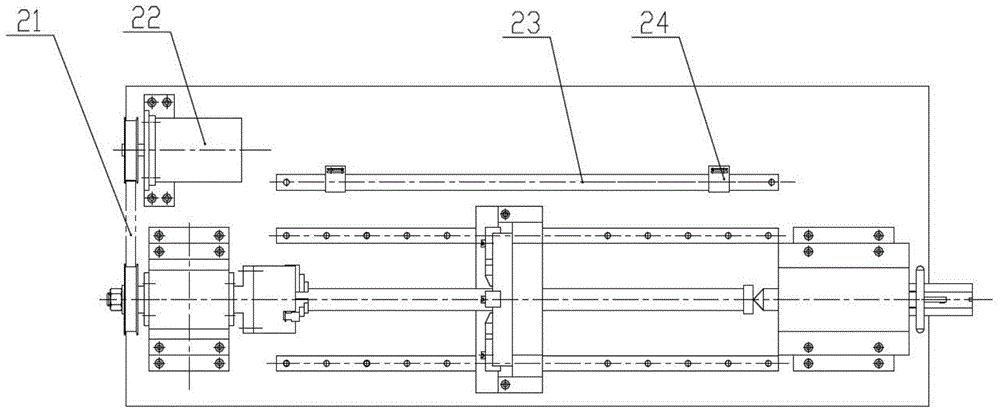

[0015] Such as figure 1 , figure 2 with image 3 As shown, a device for precision grinding screw, the device consists of a base plate 1, a pad 2, a synchronous pulley 3, a main shaft end cover 4, a main shaft positioning seat 5, a main shaft 6, a flange 7, a three-jaw automatic Centering chuck 8, workpiece 9, grinding magnetic pole group 10, arc iron 11, magnetic pole support seat 12, workpiece support 13, tailstock 14, auxiliary servo motor 15, coupling 16, screw positioning bearing seat 17 , lead screw 18, supporting plate 19, lead screw positioning bearing seat 220, synchronous belt 21, reduction motor 22 for main servo, sensor positioning seat 23, limit sensor 24, two slideways 25, lead screw nut 26 and sliding block 27, the main servo reducer 22 and the auxiliary servo motor 15 are fixed on the base plate 1 with recessed bolts, the limit sensor 24 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com