Linear type multiple row horizontal-type-like double-face machining multiple spindles drilling machine

A technology of double-sided machining and multi-axis drilling machine, which is applied in metal processing equipment, parts of boring machine/drilling machine, metal processing machinery parts, etc. Achieve the effect of improving processing efficiency, high processing accuracy and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

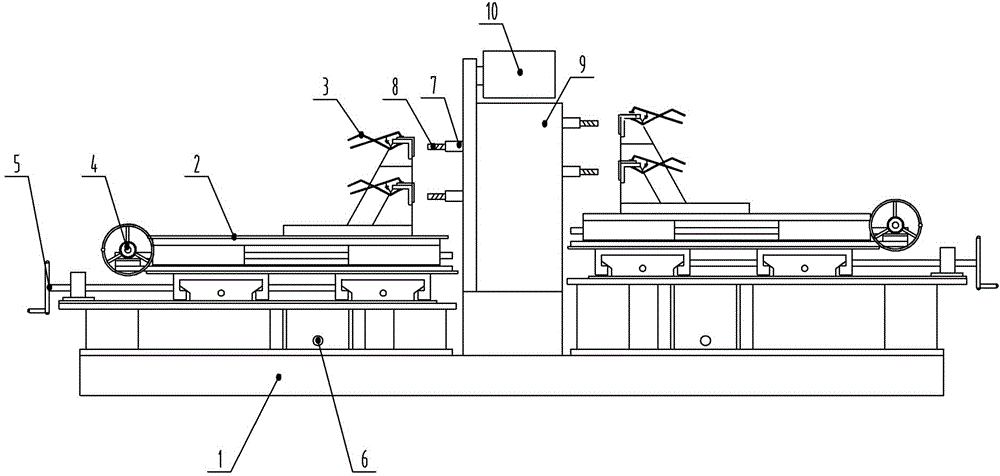

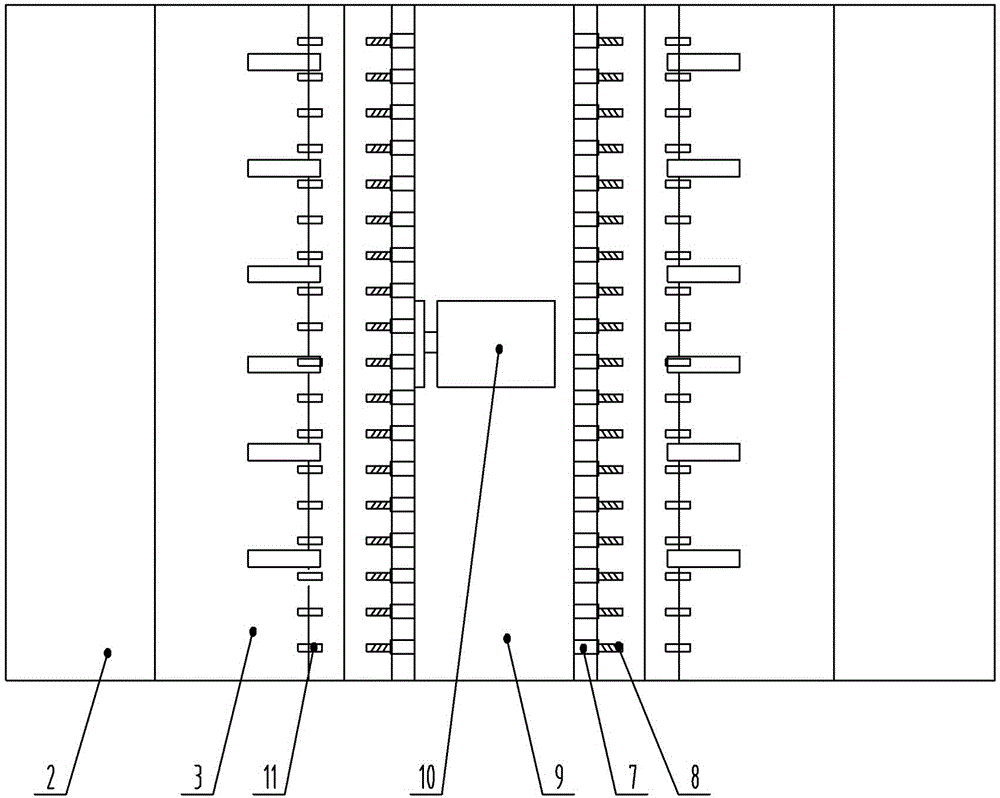

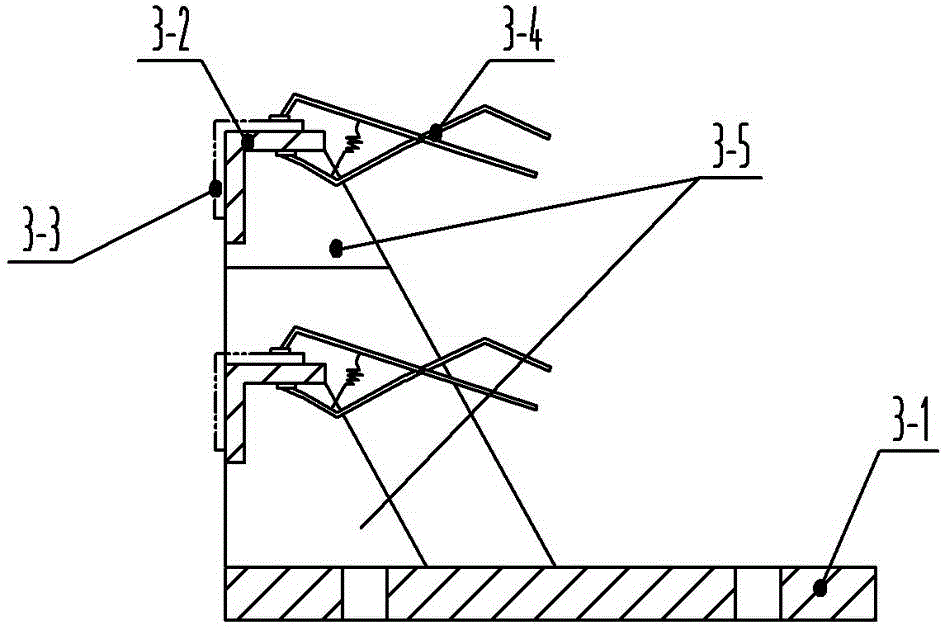

[0043] see Figure 1-2 , in the figure, the linear multi-row class horizontal double-sided processing multi-axis drilling machine of the present invention includes a common base 1, a fuselage, a workbench 2, a fixture 3 and a drilling unit, and the drilling unit is longitudinally along the top surface of the common base Centered and fixedly installed, there are two workbenches, which are respectively fixedly installed on the fuselage at both longitudinal ends of the shared base. The workbench longitudinal reciprocating movement mechanism 4, workbench transverse reciprocating movement mechanism 5 and Workbench lifting and moving mechanism 6, each workbench is equipped with a set of clamps, and the drilling unit includes a main shaft 7, a drill bit 8, a gear box 9 and a driving mechanism 10. On the horizontal frame, a cooling spray system 11 is respectively installed corresponding to each drill bit position. The main shafts are horizontally installed in the gearbox in four rows...

Embodiment 2

[0054] Present embodiment figure is not drawn. This embodiment is similar in structure to Embodiment 1, and the structurally identical parts will not be repeated here. The difference is that in this embodiment, a universal joint and its fixing mechanism are installed on the drill bit installation end of the main shaft, and between the main shaft and the drill bit. .

[0055] Compared with Embodiment 1, this embodiment is due to the addition of universal joints and adjustable spindle spacing, so that one machine can be used for multiple purposes, and rows of holes with different hole spacings can be processed at one time on the same equipment, which has a wider application range and is more convenient to use. The production cost is reduced, thus facilitating popularization and implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com